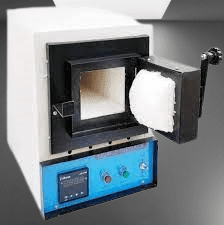

A muffle furnace is a type of furnace that is used to heat materials to high temperatures while keeping them isolated from their surroundings. This is achieved by placing the material in a ceramic or metal container known as a muffle, which is then heated in the furnace. Muffle furnaces are commonly used in materials science, chemistry, and other fields that require high-temperature processing of materials.

Working Principle of Muffle Furnace

Muffle furnaces work on the principle of indirect heating, where the heating elements are placed outside the furnace chamber, and the material to be heated is placed inside a separate chamber called a muffle. The muffle is typically made of a ceramic material such as alumina, which can withstand high temperatures and is resistant to chemical corrosion.

When the muffle furnace is turned on, an electric current is passed through the heating elements, which then heat up and radiate heat toward the muffle. The muffle, in turn, absorbs the heat and becomes hot, heating the material inside.

The temperature inside the muffle is controlled using a temperature controller, which monitors the temperature and adjusts the power supplied to the heating elements accordingly. This ensures that the material is heated to the desired temperature without overheating or underheating.

Muffle furnaces are typically used for high-temperature applications such as ashing, calcination, and sintering, where the material needs to be heated to temperatures of up to 1200°C or higher. The use of a muffle provides a controlled and isolated environment for heating materials, preventing contamination and ensuring consistent and accurate results.

Types of muffle furnaces

There are several types of muffle furnaces available, each with its own unique features and advantages. Here are some of the most common types of muffle furnaces:

- Box Furnace: Box furnaces are the most common type of muffle furnace. They consist of a metal box with a heating chamber and a muffle inside. The heating elements are located outside the muffle, and the temperature is controlled using a temperature controller. Box furnaces are versatile and can be used for a wide range of high-temperature applications.

- Tube Furnace: Tube furnaces consist of a cylindrical heating chamber with a muffle inside. The material to be heated is placed inside the muffle, which is surrounded by heating elements. Tube furnaces are often used for continuous processes such as chemical reactions and materials synthesis.

- Crucible Furnace: Crucible furnaces are designed for melting and heat-treating small amounts of material. They consist of a small muffle that can hold a crucible, which is used to contain the material being heated. The heating elements are located outside the muffle, and the temperature is controlled using a temperature controller.

- Split Furnace: Split furnaces have a removable muffle that can be easily taken out for cleaning or maintenance. This makes them ideal for applications where the muffle may become contaminated or damaged over time.

- Vacuum Furnace: Vacuum furnaces are designed to heat materials in a vacuum or low-pressure environment. They are often used for high-temperature processes that require precise temperature control and minimal contamination.

- Multi-Zone Furnace: Multi-zone furnaces have multiple heating zones, each with its own temperature control. This allows for precise temperature control across different areas of the muffle, making them ideal for applications such as crystal growth and materials synthesis.

Overall, the type of muffle furnace chosen will depend on the specific application and requirements of the user. Each type of furnace has its own unique advantages and limitations, and careful consideration should be given to factors such as temperature range, heating time, and material compatibility it is very common equipment of Quality Laboratories.

Major Components of a muffle furnace

The major components of a muffle furnace typically include:

- Heating elements: These are the components that generate heat within the furnace. They are usually made of resistance wire or ceramic materials.

- Muffle: This is the insulated chamber where the samples are placed for heating. The muffle is typically made of ceramic or other refractory materials and is designed to withstand high temperatures.

- Temperature controller: This component regulates the temperature within the furnace. It may include a digital display, setpoint adjustment, and various safety features.

- Thermocouple: This is a temperature sensor that measures the temperature inside the muffle and sends the information to the temperature controller.

- Power supply: This component provides the electrical power needed to operate the furnace.

- Insulation: This is the material that surrounds the muffle to help maintain a constant temperature inside the furnace.

- Outer casing: This is the protective outer shell of the furnace. It may be made of steel or other materials.

- Exhaust system: Some muffle furnaces may include an exhaust system to vent gases or fumes from the furnace.

Application, Benefits, and Features of a Muffle Furnace.

Muffle furnaces offer a range of features and benefits that make them a popular choice for high-temperature processing applications. Here are some of the main features and benefits of a muffle furnace:

- High-Temperature Capability: Muffle furnaces can heat materials to extremely high temperatures, typically up to 1200°C or higher. This makes them ideal for applications such as calcination, sintering, and annealing.

- Precise Temperature Control: Muffle furnaces offer precise temperature control, typically through the use of a temperature controller. This allows for accurate and consistent heating of materials, which is essential for many scientific and industrial applications.

- Isolated Environment: Muffle furnaces provide an isolated environment for heating materials, preventing contamination and ensuring consistent results. The muffle protects the material from exposure to the surrounding environment, such as air or gases.

- Versatility: Muffle furnaces are versatile and can be used for a wide range of applications, including washing, calcination, sintering, annealing, and materials synthesis.

- Easy Operation: Muffle furnaces are typically easy to operate, with simple controls and clear instructions. They require minimal maintenance and can be quickly and easily cleaned between uses.

- Safety: Muffle furnaces are designed with safety in mind, with features such as automatic shut-off and over-temperature protection. They also typically include safety equipment such as safety goggles and heat-resistant gloves.

- Durability: Muffle furnaces are built to last, with high-quality materials and sturdy construction. They are designed to withstand high temperatures and chemical exposure and can be used for many years with proper care and maintenance.

Overall, muffle furnaces offer a range of features and benefits that make them a reliable and effective tool for high-temperature processing applications. Their precise temperature control, isolated environment, versatility, and safety features make them a popular choice for scientific and industrial users alike.

Manufacturers of muffle furnaces

There are several manufacturers of muffle furnaces in India. Here are some of the leading manufacturers:

- Thermcraft India

- SGM Lab Solutions

- Labtech Engineering Company

- K. Scientific Instruments

Frequently Asked Questions:

What is the temperature range that should be considered when selecting a muffle furnace?

Answer: The temperature range of the furnace should match the temperature requirements of your application, considering both the maximum temperature required and the temperature range needed for your application.

Why is it important to consider the heating rate of a muffle furnace before purchasing?

Answer: The heating rate of the furnace should be sufficient for your application. If you require rapid heating or cooling, then look for a furnace with a high heating rate.

What should be considered when assessing the uniformity of temperature in a muffle furnace?

Answer: The temperature should be uniform across the workspace of the furnace. Consider the size of your samples and ensure that the furnace can accommodate them while maintaining temperature uniformity.

What type of atmosphere should be considered when selecting a muffle furnace?

Answer: Determine the type of atmosphere required for your application, such as air, inert gas, or vacuum. Look for a furnace that is designed to work with the appropriate atmosphere.

How can the size and capacity of a muffle furnace be determined?

Answer: Consider the size and capacity of the furnace in relation to the size of your samples and the throughput required for your application.

What features should be considered when assessing the control system of a muffle furnace?

Answer: The control system should be easy to use and allow for precise temperature control. Look for features such as programmable temperature ramp rates and data logging.

Why is it important to consider safety features when selecting a muffle furnace?

Answer: Safety features such as over-temperature protection, automatic shut-off, and safety interlocks can help prevent accidents and ensure the safe operation of the furnace.

What factors should be considered when assessing the quality and reliability of a muffle furnace?

Answer: Choose a reputable manufacturer with a proven track record of producing high-quality, reliable furnaces.

Why is it important to consider customer support when selecting a muffle furnace?

Answer: Good customer support, including technical support and after-sales service, can help ensure that any issues are addressed quickly and efficiently, minimizing downtime and maximizing productivity.

Muffle furnace price : Click on image

you may also read about Sterility Test by Open Method.

Muffle furnaces are essential for high-temperature applications in laboratories. What are the primary advantages of using a muffle furnace over other types of laboratory furnaces?