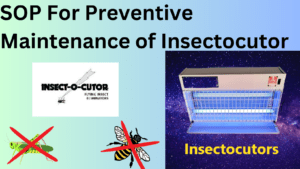

The objective of this Standard Operating Procedure for Preventive Maintenance of Insectocutor is to outline the steps and guidelines for conducting preventive maintenance on the Insectocutor (insect fly killer) to ensure its optimal performance in attracting and eliminating insects.

SOP For Preventive Maintenance of Insectocutor:

- OBJECTIVE:

- To lay down the procedure for the Preventive Maintenance of Insectocutor.

- SCOPE:

- This SOP is applicable for the Preventive Maintenance of Insectocutor installed.

- RESPONSIBILITY:

- Technician/ Officer Engineering shall be responsible for proper execution of Preventive Maintenance of Insectocutor as per SOP.

- Engineering – Head shall be responsible for reviewing the SOP and for ensuring proper execution of Preventive Maintenance of Insectocutor.

- ACCOUNTABILITY:

- Engineering – Head shall be accountable for proper implementation of the SOP.

- DEFINITIONS:

- Nil

- PROCEDURE:

- Preventive Maintenance of Insectocutor shall be executed as per the SOP No.: SOP/EN/XXXYYY – Execution of Preventive Maintenance.

- Ensure that the spare parts are available at the time of preventive maintenance.

- Preventive Maintenance of Insectocutor – Mechanical

- Check and clean the bottom tray

- Switch off the power supply of the Insectocutor.

- Remove the screw of bottom tray.

- Remove tray and de-dust with lint free cloth.

- Clean the tray with lint free cloth dipped in water.

- Refit the tray as earlier and tight the screw.

- The checking and cleaning frequency shall be daily as per SOP/HR/XXXYYY.

- Preventive Maintenance – Electrical

- Checking of control circuit

- Switch off the power supply of the Insectocutor.

- Clean the control card panel with soft brush.

- Check the control card and its components for any overheating.

- Checking shall be done after every six month.

- Checking of tube lights

- Ensure that the fluorescent lamp is glowing properly to attract the insects.

- Replace the fluorescent lamp, if observed light is less.

- Checking shall be done after every six month.

- Checking of electrical contacts

- Ensure that the power supply to the machine is switched off.

- Open contactor contact points cover.

- Remove dust from control panel with help of air blower.

- Physically checked all the contacts for pitting and carbon deposits in the contacts.

- Clean all the contacts with carbon tetra chloride or with contactor cleaner.

- Replace the contacts if found damaged or welded.

- Checking of contactors shall be done on half yearly basis.

- Post Preventive Maintenance – Check List

- Record the Preventive Maintenance details as per the Format No. : SOP/EN/XXXYYY “Preventive Maintenance Checklist for Insectocutor”.

- ABBREVIATIONS

- CRF No. : Change Request Form number

- REFERENCES

- Nil.

- DISTRIBUTION LIST

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES

- Preventive Maintenance of Insectocutor checklist: SOP/EN/XXXYYY

Preventive Maintenance of Insectocutor Checklist & Records.

| Equipment Name | Location | ||

| Equipment ID | Frequency |

| Check List | Check | Remark |

| Half Yearly Check List | ||

| Checking of control circuit and wiring. | ||

| Checking of tube lights for lamp glowing. | ||

| Checking of electrical contacts. |

Frequently Asked Questions:

What is the objective of the SOP for preventive maintenance of the Insectocutor (insect fly killer)?

Answer: The objective of this SOP is to outline the steps and guidelines for conducting preventive maintenance on the Insectocutor to ensure its optimal performance in attracting and eliminating insects.

Who is responsible for the preventive maintenance of the Insectocutor?

Answer: Maintenance personnel are responsible for the preventive maintenance of the Insectocutor.

How often should preventive maintenance be conducted on the Insectocutor?

Answer: Preventive maintenance should be conducted on the Insectocutor at least once every month or as per the manufacturer’s recommendations based on usage and environmental conditions.

What equipment and tools are required for performing preventive maintenance on the Insectocutor?

Answer: The equipment and tools required for preventive maintenance of the Insectocutor include the Insectocutor itself, safety gear (gloves, safety goggles, etc.), cleaning materials (lint-free cloths, brushes, etc.), Insectocutor cleaning spray or mild detergent solution, screwdriver (if required for accessing interior components), and replacement light tubes or bulbs (as needed).

What are the key steps involved in conducting preventive maintenance on the Insectocutor?

Answer: The key steps involved in conducting preventive maintenance on the Insectocutor are:

- Preparation

- Inspection

- Cleaning

- Light Tubes or Bulbs Replacement

- Insect Collection Tray Cleaning

- Electronic Components Check

- Calibration (if applicable)

- Electrical System Check

- Performance Test

- Documentation

- Final Checks

- Follow-up

Why is it important to regularly clean the Insectocutor and its components?

Answer: Regular cleaning of the Insectocutor and its components ensures optimal performance by removing dust, dirt, and debris that may interfere with attracting and eliminating insects.

Why is it important to maintain a maintenance log for the Insectocutor?

Answer: Maintaining a maintenance log helps track all maintenance activities performed on the Insectocutor, records any identified issues, and allows for better scheduling of future maintenance sessions. It also serves as a reference for monitoring the performance and history of the Insectocutor.

What is the significance of the performance test in preventive maintenance?

Answer: The performance test ensures that the Insectocutor is functioning effectively in attracting and eliminating insects. It verifies the brightness and effectiveness of the light tubes or bulbs in luring insects towards the device.