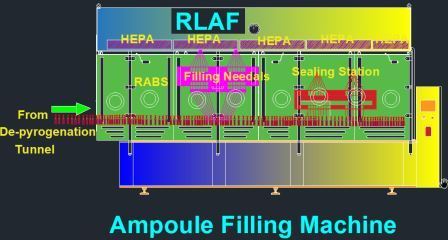

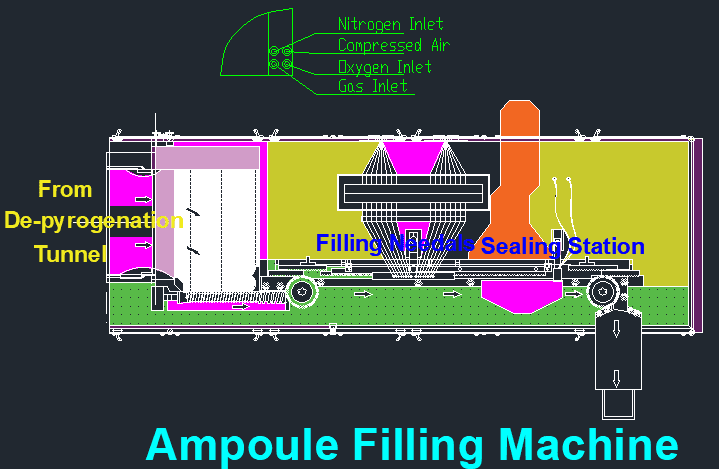

Ampoule Filling and Sealing Machine used to fill and seal D-type pre-sterilized ampoules. In our blog, we brief you about how to fill the ampules, the performance qualification of ampoule filling machines, ampoule filling machine manufacturers, ampoule filling machine uses ampoule filling process, and machine working principles. Machine designed to handle variations in ampoule neck diameters and thicknesses of readily accessible standard ampoules. The Filling unit has a frame made of SS 316 square pipes and is completely covered. The machine’s bottom side has a sizable hole for simple cleaning. Machines should operate entirely automatically with minimal manual input. Pre- and post-nitrogen filling as well as nitrogen filling during solution filling should be available at ampoules filling stations. Filling volume needs to be precise and manageable without coming into contact with any process or machine parts. The gas burner equipped with a hot suction system should be used to seal. The HEPA filter must be on the exhaust. Every operation should be performed in an aseptic space with laminar airflow and A Class with B class background.

In the pharmaceutical business, this equipment is used for automatic ampoule filling and sealing. Bottle feeding, Nitrogen pre-filling, bottle filling, Nitrogen after-filling, pre-heating, and drawbench sealing are all possible with the ampoule vertical filling and sealing machine.

It makes use of cutting-edge intelligent electronic control technologies and a stylish user interface. It properly ties together sterile and modern pharmaceutical production, and it complies with GMP standards.

This can be used individually, as well as in conjunction with other devices like a washing machine, a tunnel oven, and others to create an automatic production system.

Specification of Ampoule Filling and Sealing Machine:

| Size | Ampoule 1- 20ml |

| Capacity (bottles/hr) | 500/hr |

| Bottle Break Rate | ≤0.05% |

| Filling Accuracy | Ceramic Pump ≤±1.5% |

| Sealing Qualified Rate | ≥99.9% |

| Sealing Gas | LPG Gas, PNG + Oxygen, Natural Gas |

| Gas fuel consumption and pressure | 1.5-2.5 m3/h. 0.2-0.3Mpa |

| Oxygen consumption and pressure | 1.2-1.5 m3/h. 0.2-0.3Mpa |

Basic Operation and Principle of Ampoule Filling and Sealing Machine:

- Bottles enter this equipment via a mesh belt after drying in a tunnel oven. The belt has a block strip on one side. The strip has a fixed side. A slide-pressure spring guide rod gadget is used to link one side to the other. In addition to this, it features a position check component.

- Has positions for front and rear nitrogen filling. Additionally, a pressure monitoring device can be added. When the pressure drops below the preset level, it will stop to ensure that the nitrogen is filled for the stability of the antioxidant liquid.

- Employ the brand-new bottle-circling tool. Synchronous pulleys, which are used by gearboxes and have reliable looping and stable transmission, high certified sealing rate.

- This device features a filling cam that moves a connecting rod so that it can fill and suction. By moving the rod, the filling time can be altered.

- This device’s components include a ceramic pump, a pump fixing device, a fine-adjustment filling volume device, a no-bottle no-fill device, and a filling transmission device.

- To track the bottle-feeding location, this device uses photo electricity. The photoelectric signal will drive the solenoid valve to go through PLC when the bottle is missing. The pawl will be forced away from the swing arm, stopping the swing arm and the filling process.

- The filling needle has a separate device. According to need, each needle can be individually adjusted. Imported straight-line pin roller rail is used for needle lifting, allowing for solid movement. The liquid-contacting needle section is made of SS316L. qualified silicone tube is used in pipelines. The filling component uses approved materials that adhere to GMP standards.

- Roller uses an imported optical fiber to monitor ampoule bottle production.

- Class 100 laminar flow systems have stainless steel support frames, organic glass protection doors, and Class 100 FFU.

- A floating bacteria collector with equipment. The place is specified. an equipped platform for the coil-forming unit. The place is specified.

- Gloving the glass door with disinfectant.

- The central lubrication system on this machine is new. It may lubricate every moving component collectively to extend machine life and lower pollution.

Process management of the Ampoule Filling and Sealing Machine:

- At operating filling speeds, the filling machine should consistently and reproducibly achieve the following filling accuracy: Filling precision ought to be 1.0%.

- The equipment control system needs to be capable of adjusting and maintaining the fill rate (number of ampoules/minute) of the Ampoule Filling and Sealing Machine.

- Fill volume set must be done without making contact with any machine contact points.

- The apparatus shall regulate and keep track of the pressure and flow rate of the sterile nitrogen supply that will be utilized for nitrogen pre- and post-gassing.

- The machinery should regulate and keep an eye on the pressure and flow of the sterile gas supply that will be utilized to seal the ampoules.

- Nozzles must be drip-proof in order to prevent liquid from dropping if there is a problem maintaining GMP standards.

Failure mode recognition Ampoule Filling and Sealing Machine:

- Overload of infeed and outfeed. Pump Overload,

- Maximum Accumulation at Outfeed,

- The LAF blower is off.

- At the purging station, the gas flow decreases or increases.

- At the sealing station, the gas flow decreases or increases.

Certification & Documentations Ampoule Filling and Sealing Machine:

- GA Drawing & P&ID, Complete set of Top, Side & Elevation view.

- Ladder logic drawings.

- Motor certificates along with a flameproof certificate.

- MOC certificates of all contact & major non-contact parts including gaskets.

- Certificate of filter bag, pressure test certificate, or each component certificate.

- Complete set of DQ, and IQ Documents.

- All documents are as per URS

(OEMs) Manufacturers Ampoule Filling and Sealing Machine:

World wide there are many manufacturers of Ampoule Filling and Sealing Machines, Some of the well-known manufacturers are:

1. NKP Pharma Pvt. Ltd.

2. Snowbell Machines Pvt. Ltd.

3. Groninger & co. gmbh

4. Truking Technology Ltd.

5. Ambica Engineering Works

6. United Engineering

7. IMA PG Industries

8. Romaco Pharmatechnik GmbH

9. Bosch Packaging Technology

10. Accutek Packaging Equipment Companies, Inc.

11. Harsiddh Engineering Co.

FAQ:

1. How does the ampoule filling and sealing machine work?

Answer: This machine is designed around the idea that when an ampoule is filled and sealed, it travels slantwise while the machinery takes care of customizable elements like the container’s neck size, thickness, and shape. Empty ampoules that have been cleaned and sterilized are delivered mechanically onto a wire mesh conveyor belt through the sterilization tunnel. Afterward, the ampoules are loaded into the conveyor belt, which moves them to the segment wheel before placing them on a conveyor cradle. A set of 12, 8, 6, or 4 ampoules can be transported by the conveyor cradle through several stations. Pre-gassing, pre-filling, and post-filling are carried out in vertical positions, and the ampoule is filled with the bulk drug at a specific volume of 1 ml, 2ml, 5ml, 10ml and then sealed by melting the glass ampoule through the fusion process and sealing complete.

2. What are the 2 types of ampule sealing methods?

Answer: The most popular sealing technique is still using an open flame. A seal on the ampoule is broken in order to open it, resulting in a clean break without any glass shattering. The 2 types of most popular methods are tip and pull sealing. When sealing the tip, heat is applied evenly all around the neck to produce melting and the production of a bead. In ampoules that contain liquid, tip seals are typical. On the other hand, pull seals need a big opening, so they are utilized for containers that are packed with powder. The glass is softened by heating the neck with a burner. After that, the top is pulled and turned mechanically.

3. What is the procedure for sealing ampoules?

Answer: The most popular sealing technique is still using an open flame. The tip is sealed by applying heat all around the neck to produce melting and the production of a bead After that, the top is pulled and turned mechanically and the ampoule is sealed gently.

4. What is the use of an ampoule filling and sealing machine?

Answer: This equipment is used to fill the 1ml, 2ml, 3ml, 5 ml, and 10ml, doses of sterile drugs or injections.

6. What is the principle of an ampoule-filling machine?

Answer: Already briefed in the above article please read and check.

7. How are ampoules filled?

Answer: Cleaned and sterilized empty ampoules comes in a filling machine then 1st filled with pre-nitrogen gas then a specific volume of drug is filled through the vertical needles then again left space is purged with post-nitrogen again and then sealed by the fusion process.

8. What is the cost of an ampoule filling and sealing machine?

Answer: In India, the cost of the ampoule filling & sealing machine varies between 25 Lacs to 1.5 cr. depending on the capacity of the machine like (filling Head) ampoules filled per min.

For more technical details, best equipment vendor comparison, or any type of documentation. (SOP,DQ,IQ,OQ,PQ etc.) Please contact us at: admin@flairpharma.com

I was reading some of your blog posts on this internet site and I believe this site is very informative! Continue putting up.