Designing compressed air piping systems for pharmaceutical applications requires careful consideration of various factors to ensure compliance with industry regulations and maintain the integrity of critical processes. Compressed air piping plays a vital role in pharmaceutical manufacturing, including product handling, packaging, and instrument operation. Let’s explore some key considerations when designing compressed air systems in the pharmaceutical industry:

- Regulatory Compliance: Pharmaceutical manufacturing is subject to stringent regulations, such as Good Manufacturing Practices (GMP), and guidelines from regulatory bodies like the Food and Drug Administration (FDA). Compressed air piping systems must adhere to these regulations, including requirements for air quality, contamination control, and documentation. Compliance with standards such as ISO 8573 for compressed air purity is essential.

- Air Quality: Maintaining high air quality is paramount in pharmaceutical applications. The compressed air must be free from contaminants, such as particulates, moisture, oil, and microorganisms. Implementing appropriate filtration, drying, and sterilization techniques, including the use of high-efficiency filters and desiccant dryers, helps ensure the delivery of clean and dry compressed air.

- Material Selection: Choosing suitable materials for the compressed air piping system is critical in pharmaceutical applications. Stainless steel or pharmaceutical-grade materials are commonly used due to their corrosion resistance and compatibility with the pharmaceutical environment. The selected materials should be easy to clean, non-reactive, and capable of maintaining the required hygiene standards.

- System Zoning and Separation: Segmenting the compressed air system into zones based on the required air quality and process needs is crucial. Critical areas, such as sterile manufacturing zones, should have separate air supply and strict control to prevent contamination. Proper zoning, including the use of dedicated compressors and air treatment equipment, ensures the delivery of the appropriate air quality for each process or area.

- Validation and Qualification: Pharmaceutical facilities require extensive validation and qualification procedures to ensure the integrity and reliability of the compressed air piping system. This includes performing installation and operational qualifications, as well as regular monitoring, testing, and calibration of equipment. Documentation and record-keeping are essential for maintaining compliance with regulatory requirements.

- Redundancy and Backup Systems: To minimize the risk of production disruptions, it is crucial to incorporate redundancy and backup systems in the compressed air piping design. This may involve the use of redundant compressors, air treatment units, and storage capacity to ensure a continuous supply of compressed air in case of equipment failure or maintenance activities.

- Monitoring and Maintenance: Continuous monitoring of the compressed air system is vital to identify and address any deviations, such as pressure drops, contamination, or equipment malfunctions. Implementing a robust maintenance program, including regular inspections, preventive maintenance, and timely filter replacements, helps ensure the optimal performance and longevity of the system.

Important factors of Compressed air piping system

| Factor | Description |

|---|---|

| Pipe Material | Selecting a suitable material (e.g., steel, stainless steel) |

| Pipe Size | Determining the appropriate diameter for optimal airflow |

| Pressure Drop | Minimizing pressure losses along the piping system |

| Pipe Layout | Designing the layout to ensure efficient and even distribution of airflow |

| Fittings and Connectors | Using high-quality fittings and connectors for minimal pressure drops |

| Condensate Management | Incorporating proper drainage and moisture removal mechanisms |

| Air Quality | Implementing filtration and drying systems for clean, dry air |

| System Zoning | Dividing the system into zones for effective pressure control |

| Support and Bracing | Ensuring proper support and bracing to prevent sagging or movement |

| Maintenance and Inspections | Regularly inspecting the system for leaks, blockages, and damage |

Type of Piping Material Used for Compressed Air

When it comes to selecting the most suitable piping material for compressed air systems, various options are available, each with its own set of advantages and considerations. The choice of piping material is crucial as it directly impacts the system’s efficiency, longevity, and overall performance. Let’s delve into the characteristics of some commonly used materials to determine which one stands out as the best choice.

- Galvanized Steel:

- Galvanized steel pipes, coated with a layer of zinc, offer excellent durability and corrosion resistance. They can withstand high pressures and are relatively cost-effective. However, over time, the zinc coating can degrade, leading to potential issues such as rust and air contamination. Regular inspection and maintenance are necessary to ensure the system’s integrity.

- Stainless Steel:

- Renowned for its exceptional corrosion resistance, stainless steel is a popular choice for compressed air piping systems. It provides a hygienic and reliable solution, particularly in applications where air quality is critical. Although stainless steel is more expensive than other materials, its longevity and resistance to rust and contamination justify the investment.

- Copper:

- Copper pipes are known for their excellent heat transfer properties and resistance to corrosion. They are easy to install, maintain, and modify, making them a convenient choice for compressed air piping systems. However, copper can be prone to damage from certain lubricants and chemicals used in the system. Compatibility with the specific application should be carefully considered.

- Aluminum:

- Aluminum pipes offer lightweight and corrosion-resistant characteristics. They are easy to install, and their smooth internal surface minimizes pressure drops and allows for efficient airflow. However, aluminum pipes may have higher upfront costs, and their susceptibility to certain chemicals and abrasive particles should be taken into account.

- Plastic (Polymer) Pipes:

- Plastic pipes, such as PVC (Polyvinyl Chloride) or PE (Polyethylene), provide a cost-effective and lightweight alternative for compressed air piping systems. They are resistant to corrosion, easy to install, and offer good chemical compatibility. However, plastic pipes may have limitations in terms of pressure ratings and temperature resistance, requiring careful consideration based on the specific system requirements.

Ultimately, the choice of piping material for compressed air piping systems depends on various factors, including budget, system specifications, environmental conditions, and required air quality. Consulting with experienced professionals and considering the specific needs of the application will help determine the most suitable material that balances performance, durability, and cost-effectiveness.

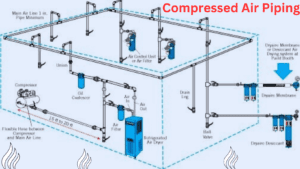

Design of Air piping system layouts, Piping Layout with Increase Pressure Efficiency

When designing air piping system layouts, several considerations can significantly enhance pressure efficiency, ensuring optimal performance and energy conservation. The arrangement and design of the piping network play a crucial role in minimizing pressure drops and maximizing the system’s overall efficiency. Let’s explore some key piping layout considerations that can help achieve these goals:

- Shorter Piping Runs: Minimizing the length of the piping runs is essential to reduce pressure losses. Longer pipelines increase friction and result in higher pressure drops. By keeping the distance between the compressor and the end-use points as short as possible, pressure losses can be minimized, enhancing the overall efficiency of the system.

- Proper Pipe Sizing: Accurate pipe sizing is crucial to maintain adequate airflow and minimize pressure losses. Undersized pipes lead to increased velocities, causing excessive pressure drops, while oversized pipes can result in sluggish airflow and unnecessary energy consumption. By carefully analyzing the required flow rates and selecting the appropriate pipe diameter, pressure efficiency can be optimized.

- Minimized Bends and Elbows: Excessive bends, elbows, and fittings introduce turbulence and friction, leading to pressure losses. By minimizing the number of turns and using long-radius bends or sweeping elbows instead of sharp angles, airflow can be streamlined, reducing energy wastage due to unnecessary pressure drops.

- Strategic Use of Reducers: Strategic placement of pipe reducers can help maintain consistent pressure levels throughout the system. Gradual reductions in pipe diameter at specific locations can compensate for pressure losses and ensure a uniform distribution of airflow, promoting energy efficiency.

- Proper Use of Branch Lines: Efficient utilization of branch lines can help optimize pressure distribution and avoid excessive pressure drops. By strategically positioning branch lines closer to the high-demand areas and using appropriate pipe sizes, pressure losses can be minimized, ensuring consistent and efficient airflow to critical end-use points.

- Effective System Zoning: Dividing the air piping system into zones based on usage patterns and pressure requirements allows for better control and pressure management. By segregating high-demand and low-demand areas, pressure can be adjusted accordingly, reducing unnecessary energy consumption and optimizing overall system efficiency.

- Adequate Support and Bracing: Proper support and bracing of the piping system prevent sagging or movement, which can lead to pressure drops and potential leaks. Ensuring that pipes are adequately supported, especially in vertical sections, helps maintain consistent airflow and minimize unnecessary pressure losses.

Frequently Asked Questions:

What is the purpose of compressed air piping design?

Answer: Compressed air piping design aims to ensure the efficient and reliable delivery of compressed air to various points of use within a system.

What factors should be considered when selecting the piping material?

Answer: Factors such as corrosion resistance, pressure rating, cost, and compatibility with the compressed air system’s requirements should be considered when selecting the piping material.

Why is proper pipe sizing important in compressed air piping design?

Answer: Proper pipe sizing is crucial to maintain adequate airflow, minimize pressure drops, and optimize energy efficiency within the system.

What are some common causes of pressure drops in compressed air piping systems?

Answer: Pressure drops can be caused by factors such as pipe friction, undersized pipes, excessive fittings or bends, and inadequate system zoning.

How can pressure drops be minimized in compressed air piping design?

Answer: Pressure drops can be minimized by selecting appropriate pipe sizes, reducing friction with smooth bends and fittings, and ensuring proper pipe layout and support.

What is the importance of air quality in compressed air piping systems?

Answer: Air quality is crucial to prevent contamination of products, equipment, and processes. Proper filtration, drying, and sterilization techniques should be employed to maintain high air quality.

Why is system zoning significant in compressed air piping design?

Answer: System zoning helps allocate and control airflow to different areas or processes based on their specific air quality and pressure requirements.

How can maintenance and inspections contribute to the optimal performance of compressed air piping systems?

Answer: Regular maintenance and inspections help identify and address issues such as leaks, blockages, or damaged components, ensuring optimal system performance and preventing potential failures.

What are the benefits of incorporating redundancy in compressed air piping design?

Answer: Redundancy ensures uninterrupted compressed air supply by providing backup systems or equipment, reducing the risk of production disruptions during maintenance or equipment failure.

Why is compliance with industry regulations essential in compressed air piping design?

Answer: Compliance with industry regulations, such as GMP and FDA guidelines, ensures the system meets quality standards and helps maintain product integrity and safety in industries like pharmaceuticals.