Epoxy flooring plays a crucial role in pharmaceutical facilities by providing a seamless, durable, and hygienic surface that can withstand heavy traffic, chemical spills, and other harsh conditions. Epoxy floors offer superior resistance to chemicals, moisture, and bacteria, making them ideal for use in laboratories, manufacturing areas, and cleanrooms. Additionally, epoxy flooring can be customized with anti-slip properties, static control, and decorative finishes to meet the specific needs of a pharmaceutical facility. Overall, epoxy flooring is an essential component in maintaining a safe, clean, and efficient pharma environment.

Types of epoxy flooring in Pharmaceuticals.

In pharmaceuticals, epoxy flooring is commonly used due to its durability, chemical resistance, and ease of maintenance. There are several types of epoxy flooring systems that are suitable for pharmaceutical facilities. Here are some of the most common ones:

- Self-Leveling Epoxy Floors: This type of epoxy flooring is ideal for pharmaceutical areas that require a smooth, seamless, and level surface. Self-leveling epoxy is poured onto the floor and spreads evenly to create a flat and uniform finish. It provides a high-gloss, durable, and easy-to-clean surface.

- Mortar Epoxy Floors: Mortar epoxy flooring is a heavy-duty option designed for areas that experience heavy foot and vehicle traffic or require resistance to impact and thermal shock. It consists of epoxy mixed with sand or quartz aggregate, creating a thicker and more robust flooring system.

- Antistatic or Conductive Epoxy Floors: In certain pharmaceutical environments, such as laboratories or cleanrooms, it is crucial to control static electricity to prevent damage to sensitive equipment or avoid electrostatic discharge. Antistatic or conductive epoxy flooring systems are specially formulated to dissipate static charges safely.

- Chemical-Resistant Epoxy Floors: Pharmaceutical facilities often deal with various chemicals and solvents that can damage conventional flooring. Chemical-resistant epoxy floors are designed to withstand exposure to a wide range of chemicals, ensuring the floor remains durable and easy to clean.

- UV-Resistant Epoxy Floors: Areas exposed to direct sunlight or artificial UV radiation can cause epoxy floors to yellow or deteriorate over time. UV-resistant epoxy flooring systems are formulated to resist UV damage, maintaining their appearance and performance for longer durations.

- Hygienic Epoxy Floors: Maintaining a high level of cleanliness and hygiene is crucial in pharmaceutical settings. Hygienic epoxy flooring is specifically designed to be seamless, smooth, and resistant to bacteria growth, making it easier to clean and maintain a sanitary environment.

These are just a few examples of the epoxy flooring types commonly used in pharmaceuticals. The choice of flooring system depends on the specific requirements of the facility, including durability, chemical resistance, hygiene standards, and electrostatic discharge control. Consulting with an expert in epoxy flooring systems can help determine the most suitable option for a particular pharmaceutical environment.

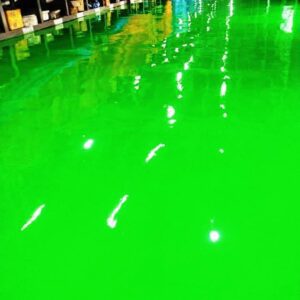

Metallic epoxy flooring

Metallic epoxy flooring is a type of epoxy flooring that incorporates metallic pigments or powders to create a unique, three-dimensional look. This flooring type is highly customizable, with a range of color options available to create a vibrant, shimmering finish. Metallic epoxy flooring is also durable and easy to clean, making it suitable for a range of settings, including commercial, residential, and industrial spaces. Its seamless and non-porous surface is resistant to moisture, chemicals, and bacteria, making it a popular choice for high-traffic areas and facilities that require a clean and hygienic environment. Additionally, metallic epoxy flooring can be combined with other decorative elements, such as stenciling and engraving, to create a truly unique flooring design.

Industrial epoxy flooring

Industrial epoxy flooring is a type of epoxy flooring that is commonly used in industrial settings such as factories, warehouses, and manufacturing plants. It is designed to withstand heavy traffic, impact, and harsh chemicals. Industrial epoxy flooring is made up of multiple layers of epoxy resin and aggregate materials, which create a strong, seamless surface that is highly durable and resistant to wear and tear.

One of the benefits of industrial epoxy flooring is its resistance to chemicals, acids, and solvents. This makes it suitable for use in areas where spills and leaks are common, such as manufacturing areas or chemical storage rooms. Additionally, industrial epoxy flooring can be customized with anti-slip properties, static control, and decorative finishes to meet the specific needs of the facility.

Overall, industrial epoxy flooring is a cost-effective and durable solution requiring minimal maintenance and a long lifespan. It is a popular choice for industrial settings due to its strength, durability, and resistance to harsh conditions.

Benefits of the Epoxy Flooring in Pharmaceuticals

| Benefit | Description |

|---|---|

| Durability | Epoxy flooring is extremely durable and can withstand heavy traffic, impact, and wear and tear. |

| Chemical Resistance | Epoxy flooring is resistant to chemicals, acids, and solvents, making it ideal for use in laboratories and manufacturing areas. |

| Hygienic Properties | Epoxy flooring is non-porous, making it easy to clean and maintain. It is also resistant to bacteria, mold, and mildew. |

| Slip Resistance | Epoxy flooring can be customized with anti-slip properties, reducing the risk of slips and falls in wet or slippery areas. |

| Customizable | Epoxy flooring can be customized with a range of colors and finishes, making it easy to match the aesthetic of any pharmaceutical facility. |

| Cost-effective | Epoxy flooring is a cost-effective flooring solution that requires minimal maintenance and has a long lifespan. |

| Quick Installation | Epoxy flooring can be installed quickly, minimizing downtime and disruption to pharmaceutical operations. |

Applications of Epoxy Flooring

Clean room epoxy flooring is a specialized type of flooring that is designed to meet the strict requirements of clean room environments. Clean room epoxy flooring is typically used in areas where cleanliness and hygiene are essential, such as in pharmaceutical facilities, hospitals, biotech labs, and electronic manufacturing plants.

Some common areas of clean room epoxy flooring application include:

- Laboratories: Clean room epoxy flooring is commonly used in research and development labs where the production of sterile and sensitive products takes place. It provides a clean and sterile environment that is necessary for the production of medications, medical devices, and other products.

- Operating rooms: Clean room epoxy flooring is also used in operating rooms to maintain a sterile environment during surgeries. It provides a seamless and non-porous surface that is easy to clean and disinfect.

- Pharmaceutical manufacturing facilities: Clean room epoxy flooring is essential in pharmaceutical manufacturing facilities where the production of drugs and medications takes place. It helps to prevent contamination and maintain a sterile environment.

- Food processing plants: Clean room epoxy flooring is also commonly used in food processing plants where hygiene and sanitation are critical. It provides a clean and sterile surface that is resistant to moisture, bacteria, and other contaminants.

Overall, clean room epoxy flooring is essential in any environment where hygiene and cleanliness are crucial. It provides a durable, seamless, and easy-to-clean surface that helps to prevent contamination and maintain a sterile environment.

Specifications of the GMP epoxy flooring

| Requirements | Specifications |

|---|---|

| Substrate Preparation | The substrate must be prepared to ensure a clean and level surface free from debris, dirt, oil, and any other contaminants that may compromise the integrity of the system. |

| Surface Profile | The surface profile of the substrate must be achieved to ensure proper adhesion of the epoxy flooring system. Shot blasting or diamond grinding is recommended to achieve a surface profile ranging from 2-3 mils. |

| Primer | Apply a suitable primer to the substrate before installing the epoxy flooring system. The primer should penetrate the substrate to ensure proper adhesion and bond strength. |

| Epoxy Flooring System | Install a high-quality epoxy flooring system that is designed to meet the specific requirements of the pharmaceutical industry. The system should be seamless, non-porous, and resistant to chemicals, stains, and abrasion. The thickness of the system should be 1/8 to 1/4 inches. |

| Cove Base | Install a cove base where the floor meets the wall to create a seamless transition and prevent the accumulation of dirt and debris. The cove base should be 4 to 6 inches high and installed at a 90-degree angle. |

| Topcoat | Apply a topcoat to the epoxy flooring system to provide additional protection against chemical exposure and abrasion. The topcoat should be UV-resistant and provide a high-gloss finish that is easy to clean and maintain. |

| Testing | Test the epoxy flooring system to ensure that it meets the GMP guidelines and industry standards. Conduct adhesion, thickness, and hardness tests to ensure the system’s durability and performance. |

| Maintenance | Develop a maintenance program that includes regular cleaning and inspections to ensure the epoxy flooring system’s integrity. Use only approved cleaning agents and methods that are compatible with the system to avoid damage or deterioration. |

epoxy flooring cost

epoxy flooring price per sq ft

| Country | PU Flooring (USD) | Epoxy Flooring (USD) |

|---|---|---|

| United States | $5 – $12 | $3 – $10 |

| Germany | $8 – $15 | $5 – $12 |

| United Kingdom | $8 – $15 | $5 – $12 |

| Australia | $6 – $12 | $4 – $10 |

| China | $4 – $10 | $3 – $8 |

| India | $4 – $10 | $3 – $8 |

| Brazil | $4 – $10 | $3 – $8 |

| Canada | $6 – $12 | $4 – $10 |

| France | $8 – $15 | $5 – $12 |

Please note that the costs provided are indicative and may vary. It’s advisable to consult with local suppliers or contractors to get precise pricing for specific projects in each country.

Frequently Asked Questions:

What is epoxy flooring?

Answer: Epoxy flooring is a flooring system made from epoxy resins and hardeners that are mixed together to create a highly durable, non-porous, and chemical-resistant surface.

Why is epoxy flooring used in pharmaceuticals?

Answer: Epoxy flooring is used in pharmaceuticals because it is easy to clean, resistant to chemicals and stains, and provides a hygienic surface that meets the strict standards of the industry.

What are the benefits of using epoxy flooring in pharmaceuticals?

Answer: The benefits of using epoxy flooring in pharmaceuticals include its durability, chemical resistance, hygiene, ease of cleaning, and ability to withstand temperature fluctuations and thermal shock conditions.

What are the different types of epoxy flooring used in pharmaceuticals?

Answer: The different types of epoxy flooring used in pharmaceuticals include self-leveling epoxy flooring, mortar epoxy flooring, and flake epoxy flooring.

What is the ideal thickness for an epoxy flooring system in pharmaceuticals?

Answer: The ideal thickness for an epoxy flooring system in pharmaceuticals is between 1/8 and 1/4 inches.

How is the substrate prepared before installing an epoxy flooring system in pharmaceuticals?

Answer: The substrate is prepared by cleaning and leveling the surface and achieving a surface profile of 2-3 mils through shot blasting or diamond grinding.

What type of primer is used before installing an epoxy flooring system in pharmaceuticals?

Answer: A suitable primer that penetrates the substrate is used before installing an epoxy flooring system in pharmaceuticals to ensure proper adhesion and bond strength.

What is a cove base and why is it important in pharmaceutical facilities?

Answer: A cove base is a seamless transition between the floor and the wall that is installed at a 90-degree angle to prevent the accumulation of dirt and debris. It is important in pharmaceutical facilities to maintain a hygienic environment.

What types of testing are conducted on an epoxy flooring system in pharmaceuticals?

Answer: Adhesion, thickness, and hardness tests are conducted on an epoxy flooring system in pharmaceuticals to ensure its durability and performance.

What is the recommended maintenance program for an epoxy flooring system in pharmaceuticals?

Answer: The recommended maintenance program for an epoxy flooring system in pharmaceuticals includes regular cleaning and inspections using approved cleaning agents and methods that are compatible with the system.

You may also read about Microbiology Guidelines

1 thought on “Role of Epoxy Flooring in Pharma 2024”