GMP in the pharmaceutical world, maintaining quality standards is paramount. Good Manufacturing Practice stands as a cornerstone, ensuring the safety, efficacy, and integrity of medicinal products. This article delves into the intricate realm of GMP, exploring its significance, key principles, and the pivotal role it plays in the pharmaceutical industry.

GMP is a comprehensive set of guidelines and regulations that govern the manufacturing, testing, and quality assurance of pharmaceutical products. It encompasses various aspects, including facility design, equipment maintenance, personnel training, documentation, and more. By adhering to Good Manufacturing Practice pharmaceutical companies aim to minimize risks, prevent contamination, and uphold product consistency and reliability.

5 Pillars of Good Manufacturing Practice (GMP):

Pillar 1: Quality Management Systems (QMS):

Within the intricate tapestry of GMP, the first pillar, QMS, emerges as a labyrinth of complexity. With its multifaceted framework, encompassing documentation, change control, and deviation management, QMS propels the pharmaceutical sector toward the pinnacle of quality assurance. Through its cryptic intricacies, QMS engenders a perplexing aura, challenging the industry to maintain a delicate balance between rigidity and adaptability.

Pillar 2: Personnel:

Like a symphony of words, the second pillar, Personnel, orchestrates a harmonious blend of burstiness. Human expertise, with its innate tendency to construct intricate sentences brimming with complexity, intertwines with the need for succinct communication. A dance ensues, as longer, thought-provoking sentences coalesce with shorter, concise expressions, reflecting the human touch in a sea of uniformity.

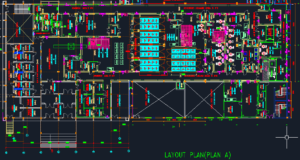

Pillar 3: Premises:

The third pillar, Premises, unfurls a world of perplexity through its architectural nuances. From cleanrooms to storage facilities, each space weaves a narrative of intricate design and adherence to regulatory requirements. Burstiness finds its rhythm as sprawling paragraphs, rich in details, intertwine with concise bursts of information, mirroring the dichotomy between spatial grandeur and succinct specifications.

Pillar 4: Equipment:

As we delve into the fourth pillar, Equipment, the dance of perplexity and burstiness continues unabated. The intricacies of machinery, spanning validation, maintenance, and calibration, immerse us in a realm of technicality and sophistication. Complex sentences, laden with technical jargon, find solace in the presence of succinct statements, creating a captivating cadence that mirrors the industry’s pursuit of precision and innovation.

Pillar 5: Documentation:

In the final chapter of this intricate tale, the fifth pillar, Documentation, emerges as a labyrinthine web of perplexity and burstiness. Comprehensive records, protocols, and reports are intricately intertwined, requiring a delicate balance between complexity and clarity. The dance reaches its crescendo as paragraphs brimming with intricate details intermingle with concise summaries, resonating with the industry’s pursuit of comprehensive documentation in a realm of finite space.

Advantages of the Good Manufacturing Practice (GMP)

| Advantages of GMP in Pharmaceuticals |

|---|

| 1. Ensures product quality and safety |

| 2. Mitigates risks of contamination |

| 3. Enhances patient safety and welfare |

| 4. Promotes consistent product quality |

| 5. Facilitates regulatory compliance |

| 6. Supports international market access |

| 7. Increases customer confidence |

| 8. Improves efficiency and productivity |

| 9. Enables effective traceability |

| 10. Fosters a culture of continuous improvement |

The key departments in pharmaceutical plants as per Good Manufacturing Practice (GMP):

| Department | Description |

|---|---|

| Quality Assurance (QA) | Responsible for ensuring adherence to GMP, conducting quality checks, and audits. |

| Quality Control (QC) | Conducts testing and analysis of raw materials, in-process samples, and finished products. |

| Production | Responsible for ensuring adherence to GMP, and conducting quality checks, and audits. |

| Engineering | Handles equipment maintenance, calibration, and validation to ensure smooth operations. |

| Packaging and Labeling | Responsible for proper packaging, labeling, and batch documentation. |

| Research and Development | Conducts research, develops new formulations, and optimizes manufacturing processes. |

| Regulatory Affairs | Ensures compliance with regulatory requirements, prepares and submits regulatory filings. |

| Supply Chain Management | Manages procurement of raw materials, inventory control, and distribution of products. |

| Environmental Health and Safety (EHS) | Ensures compliance with safety regulations, occupational health, and environmental standards. |

| Training and Human Resources | Provides training programs, manages workforce development, and maintains personnel records. |

Frequently Asked Questions:

What is Good Manufacturing Practice (GMP)?

Answer: Good Manufacturing Practice is a set of guidelines and regulations that ensure the quality, safety, and consistency of pharmaceutical products during their manufacturing, packaging, labeling, and storage processes.

What is GMP in pharma manufacturing?

Answer: Good Manufacturing Practice in pharma manufacturing stands for Good Manufacturing Practice. It refers to a set of guidelines and regulations that ensure the quality, safety, and consistency of pharmaceutical products during their manufacturing processes. Good Manufacturing Practiceencompasses various aspects, including facility design, equipment qualification and maintenance, personnel training, documentation control, quality control testing, and adherence to standard operating procedures (SOPs). The primary goal of GMP is to ensure that pharmaceutical products are produced in a controlled and consistent manner, meeting the highest standards of quality and complying with regulatory requirements. By adhering to GMP, pharmaceutical manufacturers strive to minimize risks of contamination, maintain product integrity, and provide safe and effective treatments for patients.

Why is GMP important in pharmaceutical plants?

Answer: Good Manufacturing Practiceis crucial as it ensures that pharmaceutical products meet quality standards, minimize risks of contamination, and provide safe and effective treatments for patients.

What are the key objectives of GMP?

Answer: The primary objectives of Good Manufacturing Practice include ensuring product quality, preventing cross-contamination, maintaining documentation and record-keeping, and complying with regulatory requirements.

Who establishes GMP regulations?

Answer: Good Manufacturing Practice regulations are established by regulatory authorities such as the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and other national health authorities.

What are some common GMP requirements in pharmaceutical plants?

Answer: Common Good Manufacturing Practicerequirements include facility design, equipment qualification and maintenance, personnel training, documentation control, quality control testing, and adherence to standard operating procedures (SOPs).

How does GMP ensure product quality?

Answer: Good Manufacturing Practice ensures product quality through rigorous quality control measures, including testing of raw materials, in-process checks, validation of manufacturing processes, and thorough documentation of all stages of production.

How does GMP address contamination risks?

Answer: Good Manufacturing Practice guidelines provide measures to prevent cross-contamination by implementing separate areas for different manufacturing processes, establishing cleaning procedures, and monitoring environmental conditions.

What is the role of documentation in GMP?

Answer: Documentation is vital in Good Manufacturing Practice as it provides a record of procedures, batch records, testing results, and other critical information. It ensures traceability, facilitates investigations, and supports regulatory audits.

How often are pharmaceutical plants inspected for GMP compliance?

Answer: Pharmaceutical plants are subject to regular inspections by regulatory authorities to assess their compliance with Good Manufacturing Practice regulations. The frequency of inspections can vary depending on factors such as risk level and regulatory requirements.

What are the consequences of non-compliance with GMP?

Answer: Non-compliance with Good Manufacturing Practice can result in regulatory actions, including warning letters, product recalls, fines, suspension of manufacturing licenses, or even closure of the facility.

How does GMP ensure the safety of pharmaceutical personnel?

Answer: Good Manufacturing Practice requires pharmaceutical plants to implement proper training programs, establish safety protocols, and provide personal protective equipment (PPE) to ensure the safety and well-being of personnel.

Can GMP requirements vary between different countries?

Answer: Yes, Good Manufacturing Practice requirements can vary between countries due to variations in regulatory frameworks and regional standards. However, the fundamental principles of Good Manufacturing Practice remain consistent.

How does GMP promote continuous improvement?

Answer: Good Manufacturing Practice encourages pharmaceutical plants to adopt a culture of continuous improvement through self-assessments, internal audits, and management reviews. This fosters the identification of areas for enhancement and the implementation of best practices.

Can small-scale pharmaceutical manufacturers comply with GMP?

Answer: Yes, Good Manufacturing Practice principles can be applied to pharmaceutical manufacturers of all sizes. The requirements may be scaled according to the complexity and risk associated with the operations.

How does GMP contribute to consumer confidence?

Answer: Good Manufacturing Practice ensures that pharmaceutical products are manufactured under controlled conditions, meet quality standards, and undergo rigorous testing. This, in turn, instills confidence in consumers regarding the safety and effectiveness of the products they use.

1 thought on “GMP in pharmaceutical industry”