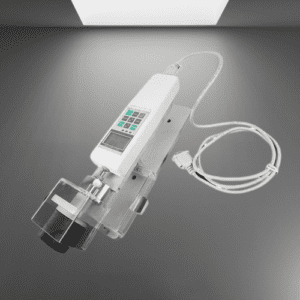

Explore the efficiency of Shore Hardness Testers for quality control in pharmaceutical plants. Learn how these instruments ensure precise hardness measurements of tablets, capsules, and other pharmaceutical products, guaranteeing compliance with industry standards and regulatory requirements.

Working Principle of the Shore Hardness Tester

The Shore hardness tester used in the pharmaceutical industry, particularly for measuring tablet hardness and other related applications, operates based on the principles of indentation hardness testing. The most common Shore hardness scales for pharmaceutical applications are Shore A and Shore D. Here’s a general overview of the working principles:

Shore A Hardness Tester (Tablet Hardness Tester):

- Indentation Method:

- The instrument features a durometer with a conical indenter.

- A known force is applied to the conical indenter, creating an indentation in the material.

- Material Response:

- The hardness of the material is determined by the depth of penetration of the indenter into the sample.

- Softer materials will allow for greater indentation, resulting in a lower hardness value.

- Measurement Readout:

- The durometer is equipped with a calibrated scale or a digital display that provides a numerical value corresponding to the material’s hardness.

- For pharmaceutical applications, this hardness value is often correlated with the tablet’s ability to withstand handling and disintegration.

- Testing Procedure:

- The operator places the tablet on a flat surface and ensures that it is positioned securely.

- The durometer is then pressed against the tablet surface with a controlled force.

- The hardness reading is recorded once the indentation stabilizes.

Shore D Hardness Tester (Capsule and Coating Hardness):

- Indentation Method:

- The Shore D hardness tester uses a durometer with a sharp-pointed indenter.

- Similar to Shore A, a known force is applied to the sharp-pointed indenter, creating an indentation in the material.

- Material Response:

- The hardness is determined by the depth of penetration of the sharp-pointed indenter.

- Harder materials will resist indentation, resulting in a higher hardness value.

- Measurement Readout:

- The durometer provides a numerical reading on a calibrated scale or a digital display.

- Testing Procedure:

- For capsule shells or coated tablets, the operator positions the durometer on the respective surface.

- The durometer is pressed against the material, and the hardness value is recorded once stabilized.

Considerations:

- Calibration: Regular calibration is essential to maintain the accuracy of the hardness tester.

- Material Variability: The pharmaceutical industry often deals with a variety of materials, and the Shore hardness tester must be suitable for the specific material being tested.

- Standardization: It’s important to follow standardized procedures and guidelines, as the regulatory environment in the pharmaceutical industry requires adherence to specific quality control measures.

Technical specifications of the Shore hardness tester

| Specification | Description |

|---|---|

| Measurement Scales | Shore A, Shore D, and possibly other Shore scales |

| Indenter Type | Conical for Shore A, Sharp-pointed for Shore D |

| Measurement Range | Typically 0-100 Shore units (may vary based on scale) |

| Resolution | Usually 1 Shore unit (digital display) |

| Accuracy | Typically within ±1 Shore unit |

| Force Application | Manual or motorized force application |

| Measurement Method | Indentation hardness testing |

| Display | Analog dial or digital display |

| Calibration | Calibratable, periodic calibration required |

| Test Surface | Flat and smooth for accurate measurements |

| Sample Size | Adequate space for placing the material to be tested |

| Operating Temperature Range | Manufacturer-specified operating temperature range |

| Power Source | Battery-powered or AC power |

| Dimensions | Compact and portable, varies by model |

| Weight | Lightweight for portability |

| Material Construction | Typically made of metal or durable materials |

| Compliance | Conforms to relevant industry standards and regulations |

| Data Output | Some models may have data output capabilities (e.g., USB) |

| Accessories | Carrying case, calibration tools, and additional accessories |

Types of the Shore Hardness Testers.

The Shore hardness test is commonly used to measure the hardness of materials, particularly polymers and elastomers. There are several types of Shore hardness testers, each designed for specific applications and materials. The two main types are Shore A and Shore D, but there are also other less common scales. Here’s an overview:

- Shore A Hardness Tester:

- Application: Used for measuring the hardness of softer materials, such as rubber and elastomers.

- Indenter Type: Conical indenter.

- Typical Range: 0 to 100 Shore A units.

- Examples of Use: Testing the hardness of shoe soles, rubber gaskets, and soft plastics.

- Shore D Hardness Tester:

- Application: Used for measuring the hardness of harder materials, such as rigid plastics.

- Indenter Type: Sharp-pointed indenter.

- Typical Range: 0 to 100 Shore D units.

- Examples of Use: Testing the hardness of plastic components, molded parts, and rigid materials.

- Shore C Hardness Tester:

- Application: Primarily used for measuring the hardness of foam materials.

- Indenter Type: Conical indenter.

- Typical Range: 0 to 100 Shore C units.

- Examples of Use: Testing the hardness of foam rubber, foam mattresses, and cushioning materials.

- Shore O Hardness Tester:

- Application: Used for measuring the hardness of soft elastomers.

- Indenter Type: Conical indenter.

- Typical Range: 0 to 100 Shore O units.

- Examples of Use: Testing the hardness of very soft rubber materials.

- Shore M and Shore E Hardness Testers:

- Application: Used for measuring the hardness of materials with extremely low hardness values.

- Indenter Type: Conical indenter.

- Typical Range: 0 to 100 Shore M or Shore E units.

- Examples of Use: Testing the hardness of extremely soft rubber and sponge-like materials.

- Shore 00 Hardness Tester:

- Application: Used for measuring the hardness of very soft materials.

- Indenter Type: Conical indenter.

- Typical Range: 0 to 100 Shore 00 units.

- Examples of Use: Testing the hardness of gel-like materials and certain soft elastomers.

It’s important to select the appropriate Shore hardness scale based on the specific characteristics and hardness range of the material being tested. Each Shore hardness type has its own scale and corresponding indenter geometry, allowing for accurate and reliable measurements across a wide range of material hardnesses.

Merits and demerits of the Shore Hardness Testers

| Aspect | Merits | Demerits |

|---|---|---|

| Accuracy and Precision | – Provides precise and repeatable measurements. | – Results may be influenced by operator technique. |

| Ease of Use | – Relatively easy to use with minimal training. | – Operator skill may impact consistency. |

| Speed of Testing | – Quick testing process for rapid quality control. | – Limited to surface hardness, not bulk properties. |

| Non-Destructive Testing | – Non-destructive method, preserving the sample. | – May not identify internal material irregularities. |

| Versatility | – Suitable for a variety of materials and shapes. | – Limited to surface testing; may not assess internal structures. |

| Cost-Effectiveness | – Generally more cost-effective than some alternative methods. | – Initial investment cost for high-quality instruments. |

| Portability | – Portable and compact for on-site testing. | – Some precision models may be less portable. |

| Industry Acceptance | – Widely accepted in pharmaceutical quality control. | – Results may not correlate with other hardness tests. |

| Maintenance | – Requires minimal maintenance. | – Regular calibration is necessary for accuracy. |

| Data Output and Recording | – Digital models may offer data storage and output capabilities. | – Analog models may require manual record-keeping. |

| Environmental Conditions | – Can be used under various environmental conditions. | – Extreme temperatures may affect measurements. |

Digital Shore hardness tester in pharmaceutical industries

Digital Shore hardness testers are commonly used in pharmaceutical industries for quality control and assurance purposes. These instruments provide a convenient and accurate way to measure the hardness of tablets, capsules, and other pharmaceutical products. Here are some features and considerations related to digital Shore hardness testers in the pharmaceutical industry:

Features:

- Digital Display:

- Clear digital displays make it easy to read and record hardness values accurately.

- Digital readings eliminate potential errors associated with analog dial interpretation.

- Multiple Scales:

- Many digital Shore hardness testers support multiple hardness scales, including Shore A, Shore D, and possibly others.

- This versatility allows for testing a wide range of materials with different hardness characteristics.

- High Resolution:

- Digital models often offer high resolution, providing more precise hardness measurements.

- User-Friendly Interface:

- Intuitive interfaces make it easy for operators to use the instrument effectively.

- Some models may include touchscreen functionality for enhanced user interaction.

- Data Storage and Output:

- Digital testers may have built-in memory for storing measurement data.

- Some models offer data output options, such as USB connectivity, for transferring results to external devices or computer systems.

- Automatic Testing:

- Some digital Shore hardness testers have motorized or automatic features for applying and releasing the testing force, improving consistency and reducing operator influence.

- Calibration and Self-Check:

- Digital instruments often have calibration features, allowing users to verify and adjust the accuracy of the measurements.

- Self-check functions may be included to ensure the ongoing accuracy of the instrument.

- Temperature Compensation:

- Some digital testers include temperature compensation features to account for variations in temperature that may affect hardness measurements.

- Compact and Portable:

- Digital Shore hardness testers are generally compact and portable, facilitating ease of use in various locations within the pharmaceutical manufacturing environment.

Considerations:

- Compliance with Standards:

- Ensure that the digital Shore hardness tester complies with relevant industry standards and regulatory requirements.

- Sample Size and Shape:

- Consider the design of the tester and whether it accommodates the size and shape of the pharmaceutical samples you need to test.

- Power Source:

- Check the power source requirements, whether the instrument is battery-powered or needs an external power supply.

- Durability:

- Evaluate the durability of the instrument to withstand regular use in an industrial setting.

- Manufacturer’s Guidelines:

- Follow the manufacturer’s guidelines for operation, calibration, and maintenance.

When selecting a digital Shore hardness tester for pharmaceutical applications, it’s essential to choose a model that meets the specific testing needs and regulatory requirements of the industry. Additionally, training operators on proper usage and maintenance is crucial to obtaining accurate and reliable hardness measurements.

Application of the Shore Hardness Tester

| Application Area | Description |

|---|---|

| Tablet Hardness Testing | Measure the hardness of tablets to ensure they meet the required standards for ease of handling, disintegration, and dissolution. Critical for quality control in tablet manufacturing. |

| Capsule Shell Hardness Testing | Evaluate the hardness of gelatin or other capsule shells to ensure they maintain integrity during production, packaging, and transport. Essential for the quality of oral medications. |

| Coating Hardness of Tablets | Assess the hardness of coatings on tablets, ensuring uniformity and integrity. Coating hardness can impact drug release profiles and overall product performance. |

| Suppository Firmness Assessment | Determine the firmness of suppositories to ensure proper insertion and dissolution characteristics. Important for patient compliance and therapeutic efficacy. |

| Ointment and Cream Consistency | Measure the hardness or consistency of topical formulations, ensuring they are easy to apply and provide the desired texture for effective skin absorption. |

| Softgel Shell Firmness Testing | Evaluate the firmness of softgel capsules to ensure they maintain structural integrity and protect the encapsulated medication. Critical for oral dosage forms. |

| Injectable Device Components | Assess the hardness of components in injectable devices, such as stoppers and seals, to ensure proper functionality and prevent issues during drug administration. |

| Quality Control of Packaging Materials | Verify the hardness of packaging materials like blister packs and seals to ensure the protection and stability of pharmaceutical products during storage and distribution. |

Frequently asked questions:

what is a shore hardness tester

Answer: The Shore A hardness tester is an instrument used to measure the hardness of weak materials such as rubber and elastomers. It uses the Shore A hardness scale and usually uses a durometer with a conical indenter.

What is Shore A hardness tester?

Answer: A Shore A hardness tester is an instrument used to measure the hardness of flexible materials such as rubber and elastomers. It operates based on the Shore A hardness scale and typically uses a durometer with a conical indenter.

How do you test Shore D hardness?

Answer: Shore D hardness is tested using a Shore D hardness tester, which has a durometer with a sharp-pointed indenter. The procedure is similar to Shore A testing but is specifically designed for harder materials such as plastics and rigid polymers.

What is the shore grade of hardness?

Answer: Shore hardness is often referred to as a grade, and it is expressed numerically. For example, a material with a Shore hardness of 70 on the Shore A scale is considered relatively hard for elastomers.

What is 70 shore hardness?

Answer: A Shore hardness of 70, whether on the A or D scale, indicates a material of moderate hardness. For example, a material with a Shore A hardness of 70 is relatively hard for elastomers, while a Shore D hardness of 70 indicates a rigid and harder plastic.

What is shore hardness used for?

Answer: Shore hardness is used to assess the hardness of materials, particularly polymers and elastomers. It is widely employed in quality control and material testing to determine a material’s suitability for specific applications.

What is the unit of hardness?

Answer: The unit of hardness depends on the specific hardness test being conducted. For example, in the Rockwell hardness test, hardness is expressed in HRA, HRB, HRC, etc. In the case of Shore hardness, no specific unit is assigned, and the result is given as a numerical value on the respective Shore scale.

What is Shore hardness A and D?

Answer: Shore hardness A is used for softer materials like rubber and elastomers, while Shore hardness D is used for harder materials like plastics. The scales are different, with Shore A typically ranging from 0 to 100, and Shore D having a higher numerical range for harder materials.

How do you measure hardness?

Answer: Hardness is measured using various methods, such as the Rockwell hardness test, Brinell hardness test, Vickers hardness test, and Shore hardness test. Each method involves applying a specific force to an indenter and measuring the depth or size of the indentation left on the material.

How is hardness defined?

Answer: Hardness is generally defined as the resistance of a material to deformation, indentation, or scratching. It is a measure of the material’s ability to withstand localized stress without permanent deformation.

What is the symbol for hardness?

Answer: The symbol for hardness depends on the specific hardness scale or method being used. For example, in the Rockwell hardness scale, the symbol is usually an “H” followed by a letter representing the scale (e.g., HRC).

What causes hardness?

Answer: Hardness in materials is often influenced by factors such as the material’s composition, crystalline structure, heat treatment, and the presence of alloying elements.

Why is hardness important?

Answer: Hardness is important because it can provide information about a material’s strength, wear resistance, and suitability for specific applications. It is a crucial factor in determining the durability and performance of materials.

Why do we remove hardness?

Answer: Hardness in water, caused by the presence of minerals like calcium and magnesium, can lead to scaling in pipes and appliances. Water softening processes are employed to remove hardness and prevent these issues.

What is an example of hardness?

Answer: An example of hardness is the ability of a diamond to scratch glass. Diamonds are one of the hardest natural materials, and their hardness is due to the strong covalent bonds in their crystal structure.

What is the hardness of water?

Answer: The hardness of water is a measure of the concentration of calcium and magnesium ions in the water. It is often expressed in terms of calcium carbonate equivalents (e.g., parts per million, ppm). Water hardness can be classified as soft, moderately hard, hard, or very hard.

I’m in shock of the depth and breadth of the blog post.

Such an alternative perspective on the subject matter.

Congratulations!