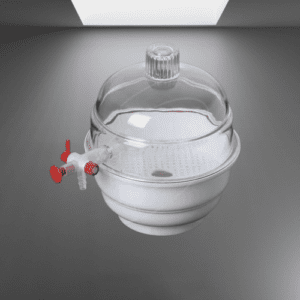

Explore the range of Laboratory Desiccators tailored for pharmaceutical plants, ensuring precise control over humidity levels to safeguard sensitive materials and samples. Our desiccators, equipped with advanced features and reliable sealing mechanisms, provide a stable environment for pharmaceutical testing, storage, and quality control. Choose from various types and sizes to meet the unique demands of your pharmaceutical laboratory, promoting sample integrity and maintaining optimal conditions for accurate results.

Working Principle of Desiccator in Pharmaceutical Laboratory:

The desiccator in a pharmaceutical laboratory operates on the principle of creating a low-humidity environment using a desiccant to ensure the preservation of sample integrity. The working steps involve moisture absorption, maintaining a dry atmosphere, and protecting pharmaceutical samples.

- Desiccant Absorption:

- Desiccant material (e.g., silica gel, calcium chloride) inside the desiccator absorbs moisture from the air.

- Low Humidity Environment:

- As the desiccant absorbs moisture, the humidity inside the desiccator decreases, creating a controlled and low-humidity environment.

- Sample Placement:

- Pharmaceutical samples, which are sensitive to moisture, are placed inside the desiccator to shield them from environmental humidity.

- Sample Protection:

- The low-humidity environment prevents moisture-induced reactions, preserving the stability and quality of pharmaceutical samples.

Applications:

- Sample Storage:

- Preserves the stability of moisture-sensitive pharmaceuticals during storage.

- Precision Weighing:

- Ensures accurate measurements in analytical processes by eliminating moisture-induced weight variations.

- Stability Testing:

- Supports long-term stability studies by providing a controlled environment for pharmaceutical products.

- Moisture-Sensitive Experiments:

- Facilitates experiments that require controlled humidity conditions, ensuring reliable and reproducible results.

Advantages:

- Preservation:

- Maintains the integrity of pharmaceutical samples by preventing moisture-related degradation.

- Accuracy:

- Enables precise and consistent measurements in laboratory procedures.

- Standardization:

- Creates a standardized testing environment, ensuring uniform conditions for reliable results.

- Prevention:

- Guards against the detrimental effects of humidity on pharmaceutical products, preserving their quality and efficacy.

Types of Desiccators:

Desiccators come in various types, each designed to meet specific laboratory requirements. Here are some common types of desiccators:

- Standard Desiccator:

- Traditional desiccators with a removable lid or door, usually made of glass or plastic. They are equipped with a desiccant, such as silica gel, to absorb moisture.

- Vacuum Desiccator:

- Similar to standard desiccators but designed to create a vacuum-sealed environment. They often have ground glass joints and a stopcock to facilitate vacuum generation.

- Automatic Desiccator:

- Features a built-in mechanism for maintaining a constant low-humidity environment. These desiccators may have electronic controls for humidity regulation.

- Gas Purging Desiccator:

- Equipped with an inlet and outlet for purging with inert gases (e.g., nitrogen or argon) to create an oxygen-free and moisture-free atmosphere.

- Dry Box Desiccator:

- A sealed enclosure with integrated gloves or ports, allowing users to handle samples inside the desiccator without exposing them to external air.

- Non-Vacuum Desiccator:

- Does not have a vacuum-sealed design but relies on the desiccant to absorb moisture from the air within the desiccator.

- Desiccator Cabinet:

- A larger cabinet-style desiccator designed for storing multiple samples or larger items in a controlled humidity environment.

- Desiccator with Humidity Control:

- Equipped with a humidity control system to maintain a specific humidity level inside the desiccator.

- Transparent Desiccator:

- Made of transparent materials, such as clear acrylic or glass, to allow visual inspection of the samples without opening the desiccator.

- Desiccator with Vacuum Pump:

- Includes an integrated vacuum pump for efficient and controlled removal of air and moisture from the desiccator chamber.

- Desiccator with Indicators:

- Features built-in indicators, such as color-changing silica gel or electronic sensors, to signal when the desiccant needs replacement or when a specific humidity level is reached.

- Portable Desiccator:

- Compact and lightweight desiccators designed for fieldwork or situations where a smaller, portable unit is more practical.

- Large Desiccator:

- Specially designed for accommodating larger samples or equipment, providing a controlled environment for large-scale applications.

- Cooling Desiccator:

- Includes additional features for cooling samples, often integrated with a cooling system or placed in a temperature-controlled environment.

- Desiccator with Gas Inlet:

- Equipped with a gas inlet for introducing gases other than air, allowing controlled atmospheres for specific applications.

The choice of desiccator type depends on the specific laboratory needs, the nature of the samples, and the desired environmental control parameters.

Different types of the Desiccants:

Desiccants are substances used to absorb and remove moisture from the air, creating a dry environment. Various types of desiccants are available, each with specific properties and applications. Here are some common types of desiccants:

- Silica Gel:

- Silica gel is a versatile and widely used desiccant known for its high adsorption capacity. It is available in different forms, including indicating and non-indicating types.

- Calcium Chloride:

- Calcium chloride is a hygroscopic salt that effectively absorbs moisture. It is commonly used in desiccant packs and can absorb water vapor at low humidity levels.

- Molecular Sieves:

- Molecular sieves are crystalline aluminosilicates with uniform pores that selectively adsorb water molecules. They are often used in applications requiring highly controlled humidity levels.

- Activated Alumina:

- Activated alumina is a porous form of aluminum oxide with a large surface area. It is effective at adsorbing moisture and is commonly used in compressed air dryers and desiccant beds.

- Montmorillonite Clay:

- Montmorillonite clay is a natural desiccant with good moisture absorption properties. It is often used in packaging to protect goods from moisture damage.

- Desiccant Packs/Dehumidifier Packs:

- These are pre-packaged desiccants often containing silica gel or clay. They are commonly used in product packaging to protect goods from humidity during storage and transportation.

- Activated Carbon:

- While primarily known for its adsorption of gases and odors, activated carbon can also adsorb some moisture. It is used in certain applications where both moisture and gas removal are essential.

- Zeolites:

- Zeolites are naturally occurring or synthetic minerals with a crystalline structure. They have high adsorption capacity and are used in various applications, including drying gases and liquids.

- Dessicant Tablets:

- These are compact tablets containing desiccant materials, often used in small enclosed spaces like pill bottles or electronic devices to prevent moisture damage.

- Hydrogel-Based Desiccants:

- Hydrogel-based desiccants consist of polymer materials that can absorb and retain large amounts of water. They are often used in medical and food packaging.

- Sodium Hydroxide (Caustic Soda):

- Caustic soda is a strong desiccant that absorbs moisture and is sometimes used in industrial applications.

- Sodium Silicate:

- Sodium silicate, also known as water glass, is a compound with desiccant properties. It is used in some drying applications, particularly in the preservation of eggs.

- Phosphorus Pentoxide:

- Phosphorus pentoxide is a powerful desiccant used in laboratory settings. It can absorb moisture from the air to form phosphoric acid.

Selecting the appropriate desiccant depends on the specific application, desired humidity level, and environmental conditions. It’s crucial to consider the compatibility and effectiveness of the desiccant for the intended use.

How to Handle Laboratory Desiccator with safety:

he safe handling of a laboratory desiccator is crucial to ensure both the integrity of the samples inside and the well-being of the laboratory personnel. Here are some guidelines for the safe handling of a laboratory desiccator:

- Personal Protective Equipment (PPE):

- Wear appropriate PPE, including lab coats, safety glasses, and gloves, when handling the desiccator.

- Inspection:

- Before use, inspect the desiccator for any damage or defects in the glass, seals, or desiccant. Do not use a damaged desiccator.

- Proper Placement:

- Place the desiccator on a stable and level surface to prevent accidental tipping.

- Avoid Rough Handling:

- Handle the desiccator with care to prevent breakage or damage. Do not slam doors or lids shut.

- Airtight Seal:

- Ensure that the desiccator has a proper airtight seal to maintain the desired low-humidity environment. Check and lubricate the seal if necessary.

- Desiccant Handling:

- Use caution when handling desiccant materials. Avoid contact with eyes, skin, and clothing. Follow proper procedures for desiccant replacement.

- Moisture Indicator (if present):

- If the desiccator has a moisture indicator, monitor it regularly to ensure the effectiveness of the desiccant.

- Use of Compatible Materials:

- Be mindful of the materials placed inside the desiccator. Some substances may react with the desiccant or the desiccator materials.

- Loading and Unloading:

- When loading or unloading samples, do so gently to avoid spills or damage to the samples and the desiccator.

- Avoid Rapid Temperature Changes:

- Do not subject the desiccator to rapid temperature changes, as this may cause stress and compromise its structural integrity.

- Cleaning:

- Clean the desiccator regularly using appropriate cleaning agents. Ensure that the desiccator is thoroughly dry before reuse.

- Emergency Procedures:

- Familiarize yourself with the location of emergency equipment, such as eyewash stations and fire extinguishers, in case of accidents.

- Training:

- Ensure that personnel handling the desiccator are adequately trained in its use and are aware of safety protocols.

- Follow Manufacturer’s Instructions:

- Adhere to the manufacturer’s guidelines and instructions for the specific desiccator model in use.

- Storage:

- When not in use, store the desiccator in a secure location to prevent accidental damage.

By following these guidelines, laboratory personnel can minimize the risks associated with desiccator handling and maintain a safe working environment.

Points to be considered before buying a Desiccator:

Purchasing a desiccator requires careful consideration to ensure it meets your laboratory’s needs and provides the desired performance. Here are some tips to consider before purchasing a desiccator:

- Application Requirements:

- Clearly define the intended use of the desiccator. Different desiccators are designed for various applications, such as sample storage, precision weighing, or controlled atmosphere experiments.

- Size and Capacity:

- Determine the size and capacity needed based on the volume and size of the samples you plan to store or handle. Ensure the desiccator is large enough to accommodate your specific requirements.

- Material Construction:

- Consider the material of construction. Desiccators are commonly made of glass, plastic, or acrylic. Glass desiccators are more fragile but offer better chemical resistance, while plastic or acrylic desiccators are durable and lightweight.

- Type of Desiccator:

- Choose the type of desiccator that suits your requirements, such as standard desiccator, vacuum desiccator, automatic desiccator, or gas purging desiccator. Each type has its advantages and is suitable for specific applications.

- Seal Integrity:

- Check the seal integrity of the desiccator. A proper seal is essential for maintaining a low-humidity environment. Look for desiccators with reliable gaskets or ground glass joints.

- Desiccant Type:

- Consider the type of desiccant used. Common desiccants include silica gel, calcium chloride, and molecular sieves. Choose a desiccant that suits your application and is easy to replace or regenerate.

- Visibility:

- Evaluate the visibility features of the desiccator. Transparent desiccators made of clear materials allow visual inspection of samples without opening the chamber, reducing the risk of contamination.

- Accessories and Features:

- Check for additional features such as built-in indicators, humidity controls, gas inlets, or vacuum pumps. Determine if these features are necessary for your specific applications.

- Ease of Use:

- Consider the ease of use, including the design of the door or lid, ease of sample loading and unloading, and the overall user-friendliness of the desiccator.

- Budget Considerations:

- Establish a budget for the purchase. Desiccator prices vary based on size, features, and materials. Consider long-term value and durability in addition to the initial cost.

- Brand Reputation:

- Choose a reputable manufacturer or supplier with a track record of producing high-quality laboratory equipment. Read reviews and gather feedback from other users if possible.

- After-Sales Support:

- Inquire about the availability of after-sales support, warranty, and customer service. Ensure that replacement parts and technical assistance are readily accessible.

- Shipping and Handling:

- Confirm the shipping and handling procedures, especially if the desiccator is delicate. Ensure that the supplier has adequate packaging and shipping protocols to prevent breakage during transit.

By carefully considering these factors, you can make an informed decision when purchasing a desiccator that aligns with your laboratory’s specific needs and applications.

What is used in a laboratory desiccator?

Answer: A laboratory desiccator typically contains a desiccant, which is a substance used to absorb moisture and maintain a dry environment inside the desiccator. Common desiccants include silica gel, calcium chloride, and molecular sieves.

What are desiccators used for?

Answer: Desiccators are used in laboratories to create a controlled environment with low humidity. They help protect sensitive materials and samples from moisture, which can affect their properties and accuracy in various laboratory processes.

What is the function of desiccant in the laboratory?

Answer: The desiccant in a laboratory desiccator absorbs moisture from the air inside the desiccator, creating a dry environment. This is crucial for preserving the integrity of samples and materials that are sensitive to moisture.

प्रयोगशाला desiccator में क्या प्रयोग किया जाता है?

Answer: प्रयोगशाला desiccator का प्रयोग विभिन्न प्रयोगों में किया जाता है, जैसे कि विशेष परीक्षण, रसायनिक प्रयोग, और सैंपल स्टोरेज के लिए उच्च-नमी वाले वातावरण को बनाए रखने के लिए।

Is a desiccator a laboratory apparatus?

Answer: Yes, a desiccator is a laboratory apparatus used for maintaining a controlled environment with low humidity to protect sensitive materials and samples.

Which salt is used in a desiccator?

Answer: Common salts used in desiccators include anhydrous calcium chloride and anhydrous magnesium perchlorate. These salts effectively absorb moisture from the air inside the desiccator.

Which liquid is used in a desiccator?

Answer: Desiccators are not typically filled with liquid. Instead, they contain a desiccant material (solid) to absorb moisture from the air inside the desiccator.

What are the advantages of a desiccator?

Answer: Advantages of using a desiccator include the preservation of sample integrity, prevention of moisture-induced reactions, and the maintenance of consistent experimental conditions in laboratories.

Why is a desiccator used for cooling?

Answer: A desiccator is not specifically designed for cooling purposes. However, by removing moisture from the air inside the desiccator, it indirectly helps in preventing temperature fluctuations caused by moisture condensation on samples and equipment.

Why is silica used in a desiccator?

Answer: Silica gel is often used in desiccators because of its high adsorption capacity for water vapor. It effectively keeps the interior of the desiccator dry, protecting sensitive materials from moisture-related damage.

What is a desiccator used for in a laboratory?

A desiccator is used in a laboratory to create a controlled environment with low humidity. It is primarily employed to protect sensitive materials and samples from moisture, ensuring the accuracy of various laboratory processes.

What is a dessicator and its uses?

A desiccator is a laboratory apparatus used for preserving the integrity of samples and materials by creating a low-humidity environment. It helps prevent moisture-related reactions and ensures accurate measurements in analytical procedures.

What is the function of desiccant in the laboratory?

The desiccant in a laboratory desiccator absorbs moisture from the air inside the desiccator, creating a dry environment. This is crucial for preserving the integrity of samples and materials that are sensitive to moisture.

What is the use of a desiccator chamber in a microbiology lab?

In a microbiology lab, a desiccator chamber may be used to create a low-humidity environment for storing or preserving microbial cultures, samples, or equipment. It helps prevent the growth of unwanted microorganisms that may thrive in high humidity.

What are the advantages of using a desiccators?

Advantages of using a desiccators in a laboratory include preserving sample integrity, preventing moisture-induced reactions, maintaining consistent experimental conditions, and protecting sensitive materials from humidity-related damage.

What is desiccation in the control of microorganisms?

Answer: Desiccation in the control of microorganisms involves the removal of moisture from the environment, which can inhibit the growth and survival of certain microorganisms. Desiccation is often used as a method of microbial control in various settings.

Which chemical is used in a desiccators?

Answer: Common desiccants used in desiccators include silica gel, calcium chloride, molecular sieves, anhydrous salts, and activated alumina.

What is an example of desiccation in microbiology?

Answer: An example of desiccation in microbiology is the use of dry conditions to control the growth of microorganisms. For instance, preserving bacterial cultures by allowing them to dry out on a solid medium can be a form of desiccation.

Which bacteria are resistant to desiccation?

Answer: Certain bacteria, known as extremophiles, may exhibit resistance to desiccation. These bacteria have adapted to survive in extreme environmental conditions, including dry or arid environments.

Can bacteria survive desiccation?

Answer: Some bacteria are capable of surviving desiccation by entering a dormant state or forming resistant structures such as spores. However, the ability to survive desiccation varies among different bacterial species.

How does desiccation affect bacteria?

Answer: Desiccation can lead to the dehydration of bacterial cells, potentially causing damage to cell structures and metabolic processes. However, some bacteria have evolved mechanisms to withstand desiccation, allowing them to survive in dry conditions.

Is desiccation bactericidal?

Answer: Desiccation can have bactericidal effects, particularly for non-spore-forming bacteria. The removal of water from the bacterial cells can lead to cell death, but spore-forming bacteria may still survive desiccation in a dormant state.

What are the different types of desiccators?

Answer: There are various types of desiccators, including vacuum desiccators, non-vacuum desiccators, and automatic desiccators. Vacuum desiccators can further be classified into those with ground glass joints and those with plastic or acrylic construction.

What is the role of CaCO3 in a desiccator?

Answer: CaCO3 (calcium carbonate) can be used as a desiccant in a desiccators. It has the ability to absorb moisture and create a dry environment inside the desiccators, helping to protect sensitive materials from humidity-related damage.