The Strip Packing machine is widely used equipment in pharmaceutical industries mostly to pack tablet capsules & pills in aluminum foil and make them safe & ready to distribute in the market, and with the help of Automation, High-speed Strip Packaging machines are handled by a wide range of tablets and capsules up to 2500 units per minute. A kind of packaging machinery known as a strip packing machine is used to create strip packs, a type of pharmaceutical packaging that includes multiple pills or tablets in a single container. The pills or tablets are placed inside the long strip of packaging material, which is then sealed by the strip packing machine. Patients appreciate this sort of packaging because it makes dosage quick and precise. Depending on the volume of production and the type of product being packaged, strip packing machines can range in size and speed from completely automatic to semi-automatic to manual. The machine’s architecture can also differ, with some producing strip packs through continuous motion and others through intermittent action.

Working & Operating Principle:

The operating & working principle of the stripping machine is very simple. The Products feed from the hopper and pass through a SS feeding system and go to heat-sealing roller cavities, the desired laminated foils from the two rollers are drawn on the sealing rollers which pack and seal the products continuously. After that, the Strip is delivered in the desired sizes by passing through vertical and horizontal Gutter assemblies. The strip packing machine packs the different variety of products like coated and uncoated tablets of any size/shape, soft and hard gelatine capsules, lozenges, toffee, chewing gum many others.

Process flow of strip packing equipment:

Strip Machine Model In the Market

In the market following models are available:

| Model: (Track) | 4 | 6 | 8 | 10 | 12 |

| Foil Width (MM) | 145 (mm) | 210 (mm) | 260 (mm) | 280 (mm) | 310 (mm) |

| Output/Min | 600-1200 | 1200- 1800 | 1800-2500 | 2250 – 3125 | 2700 – 3750 |

Main Features of strip packing machine:

- This machine is available in different models of 2, 4, 6, 8, 10, and 12 Track, with a capacity from 400 to 3000 Tab./min. with max. sealing width of 250 mm with different OEMs in the market.

- Strip Machine has standardized, and quickly interchangeable change parts as per tablet size.

- It has an adjustable foil-cutting and slitting device. Noiseless, trouble-free smooth operation

- Cavity shape and knurl design of choice.

- Confirm the airtight, leak-proof, and non-defective packing of the product.

- Suitable for most heat-scalable foils like Paper Poly, Aluminium Poly, Cello Poly, Cellophane, and Glassine Poly.

- Machines have automatic Feeding, Sealing, Slitting, and Cutting done simultaneously. Therefore, its efficiency is high, meaning production cost is decreased due to the reduction of labor cost.

- Strip conveyors of various sizes are taken off.

- The machine will be customized to different sizes and shapes.

- It can handle different heat-sealable packing laminates.

- Digital Temperature control.

- An electrical motor having 415 V/ 380 V/ 3 PH/ 50 CS/ AC Supply.

- All contact parts are SS316.

- In compliance with cGMP.

- The changed parts can easily replace.

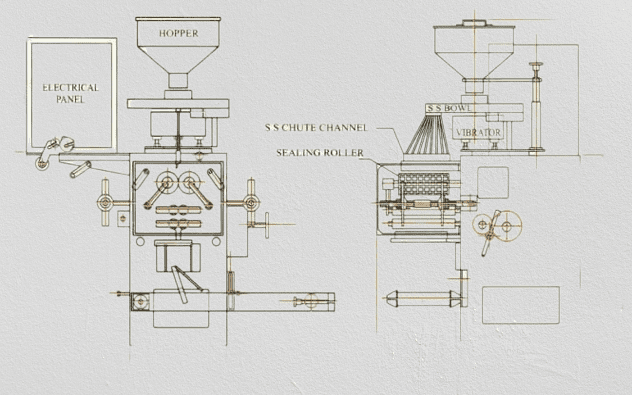

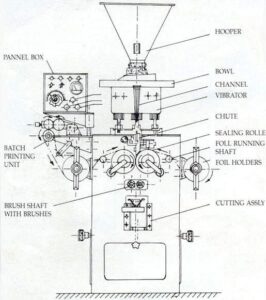

Main Parts of the Strip Machine:

- Hopper with the vibrator.

- The chute grips the product and centers them to enter into the sealing Roller.

- The sealing Roller, its temperature can be effectively maintained because of the precise temperature control device.

- Slitting, the section number and position of the decapitating are easily adjustable.

- Draw Brushes, tense the strip, and ensures that the Sealing and Cutting are precise.

- Cutter: The cutting row number can be adjusted as needed.

- Disc feeding system for odd-shaped products.

- Performing Rollers.

- Conveyor belt.

- Protective grill in front for safety.

- Electronic temperature control system with an indicator to read foil sealing temperature.

- A counter sensor for the strip counting and batch number coding system be there.

- Ensure the Feed chute pusher mechanism is there.

- All the parts which are directly in contact with the product are made of SS 316.

- IPC or the HMI is 21 CFR part 11 complied.

Critical Parameters of Strip Packing Machine in pharma

Strip packing machines are widely used in the pharmaceutical industry to package tablets, capsules, and other solid dosage forms in a strip format. Some critical parameters that need to be considered for a strip packing machine in the pharmaceutical industry are:

- Accuracy: One of the most critical parameters for a strip packing machine is its accuracy. The machine must be able to consistently and accurately dispense the correct amount of medication into each individual strip pocket.

- Speed: The speed of the machine is also an essential parameter. The machine should be able to work efficiently and produce a large volume of strip packs within a short period of time.

- Efficiency: The machine’s efficiency is another critical parameter. It should be able to minimize the amount of waste generated during the packaging process, reduce downtime for maintenance, and optimize the use of resources such as power and materials.

- Quality: The machine must ensure that the strip packs produced are of high quality, with each pocket filled uniformly, and the strip packed correctly.

- Flexibility: The machine should be flexible enough to handle different packaging formats and sizes to meet the diverse needs of the pharmaceutical industry.

- Safety: The machine should be designed with safety features that protect the operator and the product from contamination, damage, or any other hazards that may arise during the packaging process.

- Compliance: The machine should comply with regulatory standards set by the relevant authorities, such as FDA, cGMP, and ISO 9001. This is important to ensure that the products packaged meet the required quality standards and are safe for use.

Conclusion:

When any pharma industry will plan to purchase a strip packing machine, they are working on a beneficial feature of the strip packing machine is that automatic feeding, sealing, and cutting of the packets can be done simultaneously. They require a high-efficiency machine that decreases the production cost and can boost productivity with less downtime and less changeover time of the machine which may lead to the growth of their factory.

Certification & Documentations:

- GA Drawing & P&ID, Complete set of Top, Side & Elevation view.

- MOC certificates of all contact & major non-contact parts including gaskets.

- The complete set of DQ, and IQ and all documents are as per URS.

Importance of Strip packing machines

Strip-packing machines are of significant importance in the pharmaceutical industry for several reasons:

- Increased efficiency: Strip packing machines can produce strip packs at a much faster rate than manual packaging, which results in increased efficiency in the packaging process.

- Improved accuracy: Strip packing machines can accurately measure and dispense medication into each individual strip pocket, resulting in consistent dosing.

- Reduced waste: Strip packing machines are designed to minimize waste by using only the required amount of packaging material, resulting in cost savings.

- Improved product quality: Strip packing machines can produce strip packs that are of high quality, with each pocket filled uniformly and the strip packed correctly.

- Compliance with regulatory standards: Strip packing machines are designed to comply with regulatory standards set by the relevant authorities, such as FDA, cGMP, and ISO 9001, which ensures that the products packaged meet the required quality standards and are safe for use.

- Increased shelf life: Strip packing machines can produce strip packs that have an increased shelf life due to the use of high-quality packaging materials that protect the medication from moisture, light, and other environmental factors that may degrade the product.

- Convenience: Strip packs are convenient for patients as they are easy to use, and medication can be easily carried and stored, making them ideal for travel or use in emergency situations.

In conclusion, strip packing machines play a critical role in the pharmaceutical industry by improving efficiency, and accuracy, reducing waste, improving product quality, complying with regulatory standards, increasing shelf life, and providing convenience for patients.

OEM Manufacturer of strip packing machine:

World wide there are many manufacturers of Strip packaging Machines, Some of the well-known manufacturers are:

- SaintyCo

- Adinath machines

- Elmach Machines

- Ganson

- Durma Machines

-

Shree Ambica Industries

Price of strip packing machine in India:

The price of the strip packaging machine depends on the capacity requirement generally the price varies in between 12 lac to 1 cr.

For more technical details, best equipment vendor comparison, or any type of documentation. (SOP,DQ,IQ,OQ,PQ etc.) Please contact: admin@flairpharma.com