A Tablet coating machine is used to provide a coating over uncoated tablets, which protects them from environmental moisture, and chemical degradation and masks the bitter taste of the drug, etc. Also, the Coating machine shall have provision for film coating (Aqueous / Non-Aqueous) and sugar coating with interchangeable type coating pans of different capacities.

Working principles of tablet coating machines:

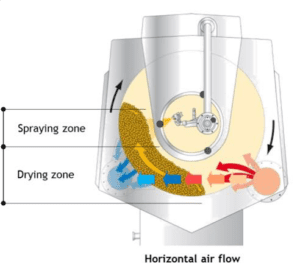

Tablet coating equipment simply worked by applying solution spray on the compressed tablet in a bed that will move horizontally and vertically. A uniform flow of heated air will dry the coat of the tablet and facilitate the evaporation of solvents.

Brief:

Compressed tablet spinning involves putting the tablets in a drum and rotating it in an orbital way. As the drum spins, a nozzle sprays a coating solution Aqueous / Non-Aqueous) onto the tablets. Automation ensures there are accuracy and an even and uniform spray on the tablets. This has baffles installed in a drum at a particular angle and turn tables facilitating sideways even spraying of the tablets, while the spaying and rotation continue, the machine pumps hot air into the drum which results in the rapid coating of the solution. After all the tablets have a uniform coating, the spinning and spraying stopped, and the tablets then proceed to the drying section.

Types of tablet coating machines:

There are many types of coating machines in the market. Mostly we categorize coating machines on the basis of their pan & working principles. Below are the types of coating machines

- Standard coating pan

- Pellegrini pan

- Immersion sword system

- Immersion tube system

- Perforated coating pan

- Accela-Cota

- Hi-coater systems

- Driacoater

- Glatt coater

- Fluidized bed or air suspension coater

- High-pressure airless systems

- Low-pressure air atomized systems

Key Process Parameters:

The coating system must be able to monitor and control the below-listed key process parameters

| Parameter | Range | Accuracy |

| Spray rate/gun | 20-90 g/min | ± 5 g/min |

| Pan speed (rpm) | 0.5-20rpm | ±1rpm |

| Airflow (Inlet air fan speed rpm) | m3/hour | m3/hour |

| Inlet air temperature | 25-90ºC | ±3ºC |

| Outlet air temperature | 25-70ºC | ±3ºC |

| Product temperature | 25-70ºC | ±3ºC |

| Inlet air humidity (desiccant system) | 3-10 g/Kg | ±1 g/Kg |

| The angle of spray guns | 0, 20, 40, 60, 80 -90deg | NA |

| Atomizing air pressure (MPA) | 1- 6 Mpa | 0.1 Mpa |

| Distance of spray guns to tablets bed | 15-30 mm | NA |

Key Quality Attributes:

The product to be processed in the required coating system must comply with the specs of the below key quality attributes.

| Parameter | Range |

| weight gain percentage for film coating | 1-5% |

| Weight gain percentage for Sugar coater | 50-100% |

| Quantity of film coat applied on tablet total surface area | 3.0-5.0mg/cm2 It depends upon the % weight build-up and tablet surface. |

Major Components of Coating Machine:

Drive Component:

- Main Power Driving Motor and brim rollers.

- Main Power Driving Motor Variable Frequency Drives (inverter).

- Speed change should be smooth without any jerk and noise.

- The minimum pan speed range should be 1 RPM

- Maximum pan speed range should be 20.0 RPM

- The machine should have intermittent drive mode for pre-heating of core tablets before the spraying phase and drying& cooling of coated tablets after the termination of the spraying phase.

- Intermittent drive mode should have settable parameters.

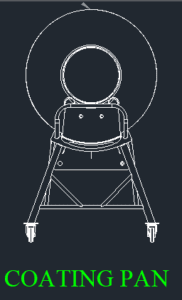

Coating Pan:

- Coating pans of specific diameter along with coating pan trays (Trolleys). It may be interchangeable as per your requirement.

- The coating pan should have an output capacity at tablet density 0.7g/ml.

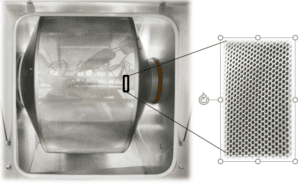

- Coating Pans should be perforated with a size of perforation 2.5 mm round.

- The tablet coater must have a percentage drum perforation of ≥25%.

- Coating Pans and their baffles should be made of SS 316L material and the surface of the pan should be polished for easy cleaning and maintenance.

- Pan should rotate in a clockwise direction during the preheating, coating process, and cleaning process and anti-clockwise direction during tablet discharge.

- The coater pan should be fitted with low-shear mixing baffles to tumble the tablet cores allowing uniform coating across the full load range of the coater.

- The tablet unloading (Discharging) should be automatic without damaging the coated tablets.

- The tablet coater should be fitted with a transparent viewing port, allowing the operator to check the internal of the pan.

| Feature | Details |

| Pan Gross Volume | L |

| Drum Diameter | mm |

| Drum Diameter (Inches) | Inches |

| Min Working Volume | L |

| Min Working Capacity | Kg |

| Max Working Volume | L |

| Max Working Capacity | Kg |

- The tablet coater must maintain negative differential pressure to the coating suite with the sample port, service door, or main front door open.

- Hot inlet air should be supplied to the coating pan through the supply duct and should move inside the coating pan. The air inside of the coating pan should move through the tablet bed and then air should exhaust to the dust collector through an exhaust duct.

Spray gun:

- Spray guns provide efficient and uniform coating, along with smoother operation

- The coating machine should be supplied with anti-bearding Schlick guns with high volume at low-pressure type.

- The spray nozzle size should be 1.0mm.

- Depending on the depth of the coating pan fixed on the coating machine, the number of guns should be increased or decreased.

- The atomizing air pressure for each gun should be monitored with the help of a human-readable and or digital measuring device and can be adjusted from the regulator and or HMI.

- Provision shall be provided for easy adjustment of spray gun angle with respect to the coating bed as well as adjustment of the distance between the coating bed and spray.

- There should be minimum exposure of solution tubes and pneumatic tubes of spray guns within the coating pan.

- If the machine (coating pan) stops suddenly or due to any alarm, the spray gun will also stop functioning to avoid any drop of solution to the tablet’s bed.

Damper:

- The machine will be supplied with Auto Damper for the inlet and an outlet with a bypass flap for hot air.

- Steam-based heating with PID-controlled face/bypass system to ensure accurate air temperature control

- Temperature measurement to measure and control the for-inlet air temperature.

- The actuator positions should be programmable based on the coating cycle (film coating or sugar coating).

Pump & it’s manifold:

- The mostly multi-head peristaltic pump distributes spray liquid evenly to each nozzle through a spray manifold inbuilt into the spray arm. Supplied mounted on the machine frame.

- Pumping system Integrated with control system

- Pressure transmitter to detect gun choking

- A rotary pump will be used for Sugar coating. The pump transports the spray liquid to the in-feed rake because in case of the sugar-coating solution is viscous.

- Frequency converter for the speed adjustment of the spray pump

- The Film coating pump with Adjustable RPM speed and The RPM of the pump can both be controlled from the HMI or the pump itself.

The calculation for the Capacity tablet coating machine:

The capacity of a tablet coating machine in the pharmaceutical industry can be calculated using the following formula:

Capacity = (Tablet weight x Batch size x Coating time) / Coating efficiency

Here are the steps to calculate the capacity:

- Determine the weight of each tablet. This can be obtained by weighing a sample of tablets and dividing the total weight by the number of tablets.

- Determine the batch size, which is the total number of tablets to be coated in a single batch.

- Determine the coating time, which is the total time required for coating a batch of tablets. This includes the time for loading and unloading the tablets, as well as the actual coating time.

- Determine the coating efficiency, which is the percentage of coating material that actually adheres to the tablets. This can be determined through trial runs and adjusting the machine settings accordingly.

- Plug in the values into the formula:

- Capacity = (Tablet weight x Batch size x Coating time) / Coating efficiency

By following these steps and using the formula, you can calculate the capacity of a tablet coating machine in the pharmaceutical industry.

Critical Parameters of a tablet coating machine

The critical parameters of a tablet coating machine in the pharmaceutical industry are:

- Inlet Air Temperature: The inlet air temperature is a critical parameter as it affects the drying time and the quality of the coating. The temperature needs to be controlled to ensure the tablets are not overheated, which can cause degradation or melting of the coating.

- Spray Rate: The spray rate is the amount of coating solution that is sprayed onto the tablets per unit of time. It is critical to ensure that the spray rate is consistent throughout the coating process to achieve a uniform coating thickness.

- Atomization Pressure: The atomization pressure is the pressure at which the coating solution is sprayed onto the tablets. It is essential to maintain the correct atomization pressure to ensure proper droplet size and distribution, which affects the quality and uniformity of the coating.

- Pan Speed: The pan speed is the speed at which the tablet bed rotates in the coating pan. The pan speed needs to be carefully controlled to ensure that the tablets are evenly coated and that there is no over-coating or under-coating.

- Coating Solution Viscosity: The coating solution viscosity is a critical parameter as it affects the spray rate, atomization, and drying time. A high viscosity can result in uneven coating, while a low viscosity can cause the coating to be too thin and easily damaged.

- Exhaust Rate: The exhaust rate is the rate at which the air is removed from the coating chamber. It is critical to maintain the correct exhaust rate to ensure that the tablets are properly dried and to prevent the buildup of solvents or coating material in the coating chamber.

- Coating Solution pH: The pH of the coating solution is important as it affects the stability and solubility of the coating material. A pH outside the recommended range can result in a poor-quality coating or even damage to the tablets.

By closely monitoring and controlling these critical parameters, a pharmaceutical manufacturer can ensure that their tablet coating machine is producing tablets with a high-quality, uniform coating that meets the required specifications.

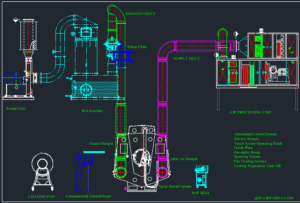

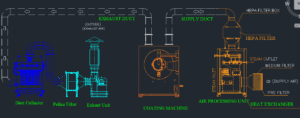

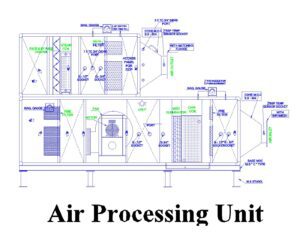

Air Processing unit (APU) with Heat exchanger:

- The APU should supply filtered and hot air to the coating pan through the supply duct.

- Double-walled inlet air unit with dehumidification and heating system. Automatically controlled inlet air temperature, airflow speed, and dehumidification chamber temperature through PID. Humidity measurement at the inlet of the machine.

- Internal wall MOC – SS304

- External wall MOC – Galvanized Iron, powder coated

- Filter frames – Aluminum

- Provided with limit switches on all doors, interlocked with control system

- Provided with HEPA validation ports

Filter Set EU4/EU7/EU13

Pre-Filter

- Pre-filter Grade EU4

- 85-90% down to 3 microns

- Equipped with a Magnehelic gauge for local differential pressure indication

Fine Filter

- Fine filter Grade EU7

- 85% down to 0.3 microns

- Equipped with a Magnehelic gauge for local differential pressure indication

HEPA Filter

- HEPA filter Grade EU13

- 997% down to 0.3 microns

- Equipped with a Magnehelic gauge for local differential pressure indication

Equipped with a differential pressure transmitter for indication on HMI.

APU consists of a heating coil to heat the filtered air. The steam valves should automatically be controlled with the help of the software PID controller working in concordance with the PLC commands and the user input temperature set on the HMI of the machine.

The present temperature of Inlet air shall be displayed on the variation in actual and the set temperature should not be more than + 3.0 °C. Temperatures (with PT100): +/- 1 % of the measuring range

The machine has auto spray cutoff provision interlock with inlet temperature (when inlet temperature breaches the upper and lower temperature set point for inlet air).

The maximum set value for inlet temperature will be 90°C (higher than this is acceptable).

Dust collector:

- Dust collector for exhaust and discharge the air from the coating pan through the exhaust duct.

- Active exhaust air deduster unit with H10 filter. Equipped with a removable dust collecting container with quick release for the dust of filter stage. Automatically controlled air purging integrated with a differential pressure switch. Additional passive H13 filter.

- The dust collector has cartridge filters through which the exhaust air should pass.

- These filters should trap the waste powders and suspend them onto the tray at the bottom of the dust collector.

- Dust collector has the function of exhausting and discharging the air from the coating machine. By going through the dust collector, air with the dirt is cleaned by the cartridge filter. The temperature of the exhausted air should be checked by the sensor and displayed in HMI

- The dust collector should consist fan and the speed of the fan is controlled by the inverter

Wet Scrubber:

A wet scrubber is used by transferring solid particles from a gas stream to a liquid, wet scrubber procedures remove them from the stream. The energy required to touch the gas stream with the scrubber liquid determines how effectively a wet scrubber collects particles.

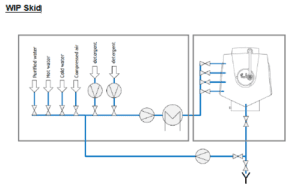

CIP System:

- The machine shall be supplied with a CIP system (Clean In Place System) that

- The CIP system should supply high-pressure water the to CIP points located in the coating pan.

- The clean-In-Place system consists of strategically placed washing nozzles to ensure hassle-free cleaning validation in a low-downtime environment.

- Machine constructed to minimize crevices and difficult-to-reach areas

- WIP Skid consists of a Media supply with connections for o Warm water

- Cold water

- Purified water

- Compressed air

- These connections are equipped with check valves to prevent back-flow

- Flow switch

- Booster Pump

- Distribution valves

- Control System

- CIP system ensures complete cleaning of a coating pan, spray guns, supply, and exhaust ducts, and ensures complete drains of water used for cleaning from the machine.

- All wash water contact parts must be compatible with pharmaceutical-grade detergents with a range of 1.5 to 13.7 pH.

Control System:

The machine has a fully automated control panel

- The machine has both supply temperature controller mode and exhaust temperature controller mode.

- The machine has displayed DPIP (Differential pressure inside the pan) and DPIE Differential pressure inside the exhaust.

- The machine has displayed supply velocity (In CFM) and Humidity (in obsolete term g/kg).

- A pressure gauge shall be provided for measuring Differential pressure across the HEPA filter.

- The auto-coating should be recipe controlled.

- The CIP cycle should be recipe controlled.

- The operator should not be able to modify or delete the parameters of the stored recipe.

The recipe should have set points for the following (Not limited to):

- ►Exhaust Temperature set

- ►Exhaust Fan Speed

- ► Supply Temperature

- ► Supply Fan Speed

- ► Spray Atomizing Air pressure

- ► Coater Differential Pressure

- ► Coater Pan Speed

- ► Solution Pump Speed

- ►Machine should have audiovisual alarms.

- ►Machine should have alarms for the following:

- ► Main air shortage

- ► Trip coater motor

- ► Trip exhaust fan motor

- ► Trip supply fan motor

- ► Completed Film coating/sugar coating

- ► Exhaust temp over limit/exhaust temp low limit

- ► Glass open

- ► Buzzer Off/On Select

- ► Product temp over / low limit

- ► Supply temp over / low limit

- ► Solution tank temp over / low limit

- ► D.P.I.P High/low

- ► D.P.I.E High/low

- ► Communication failure 21CFR Part 11 requirements (There are bare minimum requirements)

Safety Features:

- The machine shall have to earth.

- Safety interlock to prevent operator access to rotating parts.

- Emergency switch and control panel for immediate shut down of the machine.

- In a power failure or emergency stop condition, all equipment or component parts not required for equipment protection MUST have all stored energy dissipated or prevented for activation by a fail-safe system

- The coating machine shall be flameproof with the following specification,

- Flameproof – Suitable for groups II (B) and III (B)

- Rating – Exd (Atex approval)

- Ingress protection (IP) – 65 (minimum)

- Temperature rating – it should be minimum T4

- MOC of product contact parts – SS316L / higher grade with surface finish Ra of <0.5 μm

- Contact parts provided in food grade Silicon/EPDM

Documentation required:

- MOC / COA certificate of contact and noncontact PARTS.

- MOC food grade and nontoxic certificates of contact and noncontact gaskets

- Electrical diagram

- Sets of maintenance and operational manual

- Functional specification and design specification (FS/DS)

- Calibration certificates of gauges and instruments with traceability certificate

- Operational manual of automated or PLC system / MMI

- Operational & maintenance manuals for the coater.

- Maintenance Manual

- PLC input/output list

- PLC and control panel wiring diagram

- List of alarm and their rectification procedure

- List of functional authorization

- FAT / SAT document

- GA (General alignment) drawing

- Schematic diagram of the machine showing overall dimension (as built drawing)

- System architecture diagram configuration and calibration certificate

- Alarm list (diagnostic and system created)

- FAT and installation qualification protocol

- Flameproof certificate of motor and accessories

- Certificate of HEPA filter and test certificate and certificate of another filter

- P&ID (Piping and instrumentation diagram)

- PLC backup

- Complete set of DQ, and IQ Documents.

- All documents are as per URS

Manufacturer of Coating Machine

There are lots of manufacturers worldwide who manufacture Tablet Coating machines, some of the best manufacturers are below:

- Glatt.

- Solace Engineers.

- Sejong.

- Gea Process equipment.

- ACG

- Prism

Frequently Asked Questions (FAQ) for Coating Machine:

For more technical details, best equipment vendor comparison, or any type of documentation. (SOP,DQ,IQ,OQ,PQ etc.) Plase contact:admin@flairpharma.com

Thanks