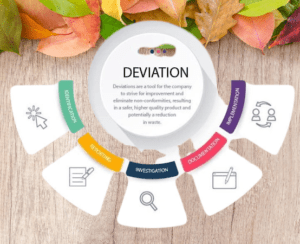

Deviation Management will navigate with excellence & precision. Explore a systematic approach to address unexpected events, ensuring product and process excellence. Learn how identification, root cause analysis, and strategic actions minimize adverse effects, fostering continuous improvement. Elevate product quality, enhance compliance, and streamline operations with this indispensable tool in the world of quality assurance.”

What is Deviation Management?

Deviation management is a systematic and indispensable approach to handling unexpected events or variations from established processes or specifications. These deviations, stemming from equipment malfunctions to human errors, have the potential to significantly impact product quality, safety, and compliance. The essence of deviation management lies in identifying, assessing, and, most importantly, resolving these deviations in a manner that minimizes their adverse effects.

Key Components of Deviation Management:

- Identification and Documentation:

- Recognize and document any deviation from standard operating procedures.

- Lay the foundation for a structured response.

- Assessment and Root Cause Analysis:

- Determine the cause of the deviation through robust root cause analysis (RCA).

- Address the “What went wrong?” and “Why did it go wrong?” questions.

- Risk Evaluation:

- Assess the potential risk associated with each deviation.

- Prioritize actions based on the level of impact, allocating resources strategically.

- Corrective and Preventive Actions:

- Implement corrective actions addressing the root cause.

- Enforce preventive actions to thwart similar deviations in the future.

- Documentation and Compliance:

- Maintain comprehensive records throughout the process.

- Demonstrate compliance with quality standards and regulatory requirements.

Benefits of Deviation Management:

Deviation management extends beyond mere problem-solving; it’s a catalyst for continuous improvement and learning. Here are some key benefits:

- Improved Product Quality:

- Addressing and preventing deviations ensures consistent delivery of high-quality products, fostering customer trust and loyalty.

- Enhanced Compliance:

- Crucial in regulated industries, deviation management aids in maintaining compliance with industry standards, mitigating the risk of penalties and legal issues.

- Cost Reduction:

- Prevention of deviations leads to cost savings by reducing rework, minimizing waste, and lowering operational costs.

- Increased Efficiency:

- Efficient deviation management processes streamline operations, reducing downtime and enhancing overall productivity.

Embracing Deviation Management:

In a realm where quality assurance is non-negotiable, deviation management transforms from an option to a necessity. It empowers organizations to navigate unforeseen challenges while upholding their commitment to excellence. By fostering a culture of continuous improvement, organizations leverage deviation management as a tool for growth, innovation, and ultimate success.

The Steadfast Anchor in Complexity:

As industries evolve and complexities increase, deviation management remains a steadfast anchor. It ensures that organizations stay on course, unwavering in their commitment to quality, and equipped to tackle the dynamic challenges of the ever-evolving landscape.

What is the meaning of deviation management?

Answer: Deviation management is a systematic approach to handling unexpected events or variations from established processes or specifications. It involves identifying, assessing, and resolving deviations in a way that minimizes their adverse effects on product quality, safety, and compliance.

What is a deviation process?

Answer: A deviation process is a series of steps taken to manage and address unexpected events or variations from established procedures. This typically includes identification, documentation, root cause analysis, risk evaluation, and the implementation of corrective and preventive actions to ensure continuous improvement.

Why is deviation management important?

Answer: Deviation management is important for several reasons:

- Ensures consistent and high-quality products or services.

- Helps organizations maintain compliance with industry standards and regulations.

- Leads to cost reduction by preventing deviations and reducing operational costs.

- Streamlines operations, reducing downtime and improving overall productivity.

- Fosters a culture of continuous improvement and learning from deviations.

What is a deviation in GMP?

Answer: In Good Manufacturing Practice (GMP), a deviation is any departure from established procedures or specifications that may affect product quality or safety. GMP deviations are closely monitored and managed to ensure compliance with regulatory requirements.

What are the 4 categories of deviation?

Answer: The 4 categories of deviation are:

- Critical Deviation: Has a significant impact on product quality, safety, or efficacy.

- Major Deviation: Has a noticeable but not critical impact on product quality.

- Minor Deviation: Has minimal impact on product quality or safety.

- Critical Nonconformance: A severe deviation posing a threat to product quality, safety, or regulatory compliance.

What is deviation example?

Answer: An example of a deviation could be a manufacturing process running at a temperature slightly outside the specified range, impacting the quality of the final product.

What is deviation and types?

Answer: Deviation refers to any departure from established processes or specifications. Types of deviations include process deviations (variations in manufacturing processes), equipment deviations (issues with machinery), human error deviations (mistakes in the production process), and documentation deviations (discrepancies in record-keeping).

How to calculate deviation?

Answer: Calculating deviation depends on the context. In statistical terms, it may involve measuring the difference between observed values and a central value like the mean.

What is the limit of deviation?

Answer: The limit of deviation refers to the acceptable range or threshold beyond which a deviation is considered significant and requires corrective action.

What is a deviation quality?

Answer: Deviation quality refers to the extent to which a deviation may impact the quality of a product or process.

What is major deviation?

Answer: A major deviation is a significant departure from established procedures that may impact product quality, safety, or compliance.

What is the scope of deviation management?

Answer: The scope of deviation management encompasses the entire process from identification to resolution, ensuring continuous improvement and adherence to quality standards.

What is a deviation report?

Answer: A deviation report documents the details of a deviation, including its identification, analysis, and the actions taken to address and prevent its recurrence.

How do you write a deviation report?

Answer: Writing a deviation report involves:

- Clearly stating the deviation and its specifics.

- Investigating and explaining why the deviation occurred (root cause analysis).

- Assessing the potential impact and prioritizing actions (risk evaluation).

- Outlining corrective and preventive actions taken.

- Maintaining thorough documentation for compliance and future reference.

Good post