Discover the significance of the Reynolds number in purified water systems, its role in preventing biofilm formation, ensuring water quality, and maintaining optimal flow dynamics. Learn how this crucial calculation helps regulate laminar, transitional, and turbulent flow for efficient water purification processes. Ensuring the purity of water is critical in various industrial applications, including pharmaceuticals and food production. Among the factors affecting purified water systems, the Reynolds number plays a significant role. This dimensionless value helps evaluate water flow behavior, contributing to the overall quality and effectiveness of purification systems.

What is Reynolds Number?

The Reynolds number is a calculation that predicts the flow pattern of fluids within a pipeline. First introduced by Osborne Reynolds in 1883, this metric classifies the fluid flow into three categories: laminar, transitional, and turbulent. These classifications are determined by the interaction of fluid velocity, pipe diameter, and fluid viscosity.

Reynolds Number’s Role in Purified Water Systems

Maintaining microbiological purity in purified water systems is a crucial objective. The Reynolds number assists in monitoring and controlling water turbulence, which in turn, helps maintain this purity. By analyzing the water flow in relation to the Reynolds number, operators can prevent the formation of biofilms, which are bacterial layers that cling to solid surfaces within the pipeline.

How the Reynolds Number Determines Flow Patterns

The Reynolds number distinguishes the flow of fluids as either laminar, transitional, or turbulent:

- Laminar Flow (Reynolds number < 2300): Water flows smoothly, with particles moving in parallel layers. This low-velocity flow minimizes turbulence, reducing interaction between fluid layers.

- Transitional Flow (Reynolds number 2300-4000): As the flow rate increases, the water begins to shift from a laminar state to a more disorderly pattern. In this range, flow patterns are neither fully laminar nor turbulent.

- Turbulent Flow (Reynolds number > 4000): At high velocities, water moves chaotically, with particles swirling in a disordered manner. This turbulent state is essential for removing contaminants such as biofilms from the pipeline walls.

Preventing Biofilm Formation

Biofilms are a major concern in water purification systems, as they promote the growth of bacteria and other microorganisms. If left unchecked, biofilms can compromise water quality and system performance. However, by maintaining a Reynolds number above 4000, which ensures turbulent flow, the likelihood of biofilm formation is significantly reduced.

In purified water systems, it is often recommended to maintain a flow velocity of at least 1.2 m/s, corresponding to a Reynolds number greater than 10,000. This ensures sufficient turbulence to prevent biofilm accumulation, keeping the system clean and reducing the need for chemical sanitization.

How to Calculate the Reynolds Number

The Reynolds number can be calculated using the following formula:

Re = (Pipe Diameter × Velocity × Density) / Viscosity

This calculation allows system operators to fine-tune water flow rates to maintain an optimal Reynolds number. By adjusting variables such as pipe diameter and flow velocity, the Reynolds number can be controlled, ensuring that the water remains turbulent enough to prevent contamination.

The Historical Relevance of Reynolds Number

Though developed over a century ago, the Reynolds number remains a fundamental criterion in fluid dynamics and purified water systems. The experiment that Osborne Reynolds conducted using dye injection in a flowing liquid still serves as the basis for understanding fluid flow patterns today. His classification system—laminar, transitional, and turbulent—continues to guide modern-day engineers in designing efficient water purification systems.

The Impact of Reynolds Number on System Design

When designing a purified water system, the Reynolds number is an essential consideration. Maintaining turbulent flow is crucial not only for biofilm prevention but also for ensuring that water quality remains high. A well-designed system incorporates this flow control to minimize downtime and avoid the costs associated with biofilm removal.

Application of Reynolds Number in Various Industries

Industries such as pharmaceuticals, food production, and even cosmetics rely heavily on purified water systems. In these industries, even minor contamination can lead to product recalls or harm to consumers. The Reynolds number plays a vital role in ensuring that these systems remain uncontaminated by regulating flow rates to prevent biofilm formation and microbial growth.

By maintaining the proper Reynolds number, companies can ensure that their water purification systems operate at optimal efficiency, delivering high-quality water free from harmful contaminants. This simple yet effective metric has proven indispensable in industries where water purity is non-negotiable.

Conclusion

The Reynolds number is more than just a mathematical concept; it is a key player in maintaining the purity and efficiency of water systems. In purified water systems, ensuring a high Reynolds number promotes turbulent flow, preventing biofilm formation and microbial contamination. Through its careful regulation, industries can maintain stringent water quality standards, making it an invaluable tool in modern water system design.

Frequently asked question

What is the significance of the Reynolds number?

Answer: The Reynolds number is crucial for determining the type of flow in a fluid system. It helps differentiate between laminar, transitional, and turbulent flow, which is essential in optimizing the design and operation of fluid systems like water purification processes.

What is the flow rate of purified water?

Answer: The flow rate of purified water depends on the specific system and its design. However, in most industrial applications, a flow rate of 1.2 m/s or higher is recommended to ensure turbulent flow and maintain water quality by preventing biofilm formation.

What is the critical Reynolds number for water?

Answer: The critical Reynolds number for water typically falls around 2300, below which the flow is laminar, and above which the flow becomes transitional and, eventually, turbulent when the Reynolds number exceeds 4000.

What does the Reynolds number tell us?

Answer: The Reynolds number tells us whether the flow of a fluid is laminar, transitional, or turbulent. It indicates how fluid particles move in relation to one another, which is important for maintaining system efficiency and preventing contamination in purified water systems.

What if the Reynolds number is high?

Answer: A high Reynolds number (greater than 4000) indicates turbulent flow, which is beneficial in systems like purified water distribution, where turbulence helps prevent the formation of biofilms and promotes better mixing and cleaning within the system.

What are the practical applications of the Reynolds number?

Answer: The Reynolds number is used in various industries such as water purification, HVAC systems, and fluid transportation systems. It helps engineers design efficient piping systems by controlling flow characteristics to prevent contamination, optimize energy use, and ensure smooth operation.

What is the quality of purified water?

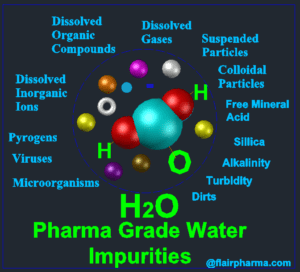

Answer: Purified water is of high quality, free from contaminants such as bacteria, viruses, dissolved salts, and particulates. The level of purification varies depending on the process used, but it generally meets strict industry standards for chemical and microbial purity.

What is flow rate in water purifier?

Answer: The flow rate in a water purifier refers to the volume of water processed per unit of time, often measured in liters per minute (L/min). The flow rate depends on the purifier’s design, filtration method, and intended application, ranging from a few liters per minute in household systems to much higher rates in industrial setups.

What is the range of purified water?

Answer: The range of purified water typically refers to its level of purity, which can be classified as deionized, distilled, or reverse osmosis (RO) water. The specific range depends on the purification process and the application, with conductivity levels typically being below 1 microsiemens per centimeter (µS/cm) for high-purity water.

What is Reynolds number in water systems?

Answer: In water systems, the Reynolds number helps determine the flow regime of water in pipes or channels, allowing engineers to maintain turbulent flow for efficient cleaning and biofilm prevention, especially in purified water systems.

What is the threshold for Reynolds number?

Answer: The threshold for the Reynolds number is 2300. Below this value, the flow is considered laminar. The flow becomes transitional between 2300 and 4000 and becomes fully turbulent above 4000.

What is the critical Reynolds number 500000?

Answer: A Reynolds number of 500,000 typically applies to flows in external systems, such as air or water over aircraft wings or ships. At this number, flow transition between laminar and turbulent behavior can occur for large-scale systems like those involving external aerodynamics or hydrodynamics.

What is the pH of purified water?

Answer: The pH of purified water is generally neutral, around 7. However, due to the absorption of CO₂ from the air, it may be slightly acidic, ranging between 5.5 and 7.

What is the pH of pure water?

Answer: The pH of pure water is exactly 7, which is neutral on the pH scale. Pure water has no dissolved impurities that could affect its pH.

How pure is purified water?

Answer: Purified water is extremely pure, with most impurities, including minerals, bacteria, and chemicals, removed through processes like reverse osmosis, deionization, or distillation. Its purity levels can reach over 99.9% depending on the purification method.

What happens when Reynolds number is high?

Answer: When the Reynolds number is high, the flow becomes turbulent, which enhances mixing and improves the efficiency of cleaning and purification processes by preventing the formation of deposits like biofilms.

How is Reynolds number used?

Answer: The Reynolds number is used to predict and control fluid flow patterns, allowing engineers to design systems that optimize flow behavior, whether to reduce energy consumption or prevent contamination in applications like purified water systems, HVAC, and aerodynamics.

What is the critical Reynolds number?

Answer: The critical Reynolds number typically refers to the value around 2300, which marks the transition between laminar and turbulent flow in pipes.

What is the formula for the Reynolds number?

Answer: The formula for the Reynolds number is:

Re = (Pipe Diameter × Fluid Velocity × Fluid Density) / Fluid Viscosity

What is the application of Reynolds number?

Answer: The Reynolds number is applied in fluid mechanics to control and predict flow patterns in various systems, including pipelines, airflows, and purification processes, to ensure system efficiency, prevent contamination, and maintain operational standards.

What is the significance of low Reynolds number?

Answer: A low Reynolds number indicates laminar flow, where fluid particles move smoothly in parallel layers. This type of flow minimizes turbulence, which is ideal in applications that require stable and orderly movement, but may not be suitable for processes like water purification, where turbulence is needed to prevent biofilm formation.