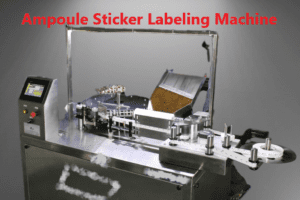

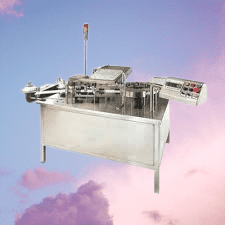

The purpose of this (Standard Operating Procedure) SOP For Preventive Maintenance of Ampoule Labeling Machine is to outline the steps and guidelines for performing preventive maintenance on the Visual Inspection Machine to ensure its optimal performance, minimize downtime, and maintain product quality.

SOP For Preventive Maintenance of Ampoule Labeling Machine

- OBJECTIVE:

- This SOP is describing the Preventive Maintenance procedure of Ampoule Labeling Machine.

- SCOPE:

- This SOP is applicable for Preventive Maintenance of Ampoule Labeling Machine; at the Production and QC department .

- RESPONSIBILITY:

- Engineering – Head or designee shall be responsible for reviewing the SOP and for ensuring proper execution of preventive maintenance.

- User Department – Head shall be responsible to provide the equipment and Engineering Head or designee ensures that the preventive maintenance of equipment is done as per schedule.

- IPQA Person shall review the relevant document for cGMP compliance and quality system requirements.

- Head – QA (or) designee shall be responsible for review and approval of the SOP and ensuring its compliance.

- ACCOUNTABILITY:

- Engineering – Head shall be accountable for proper implementation of the SOP.

- DEFINITIONS:

- Preventive Maintenance: The preventive maintenance describes all scheduled work done on a routine, predefined basis to maintain facilities, equipment, utilities and devices in good status in order to ensure reliable performance.

- PROCEDURE:

- Precautions:

- Switch off the power supply before starting preventive maintenance.

- Check & ensure that no objects & tools are left out in the area after completing maintenance of the machine.

- Fix the tag on Electrical panel for ‘Under Maintenance’ & Remove the Tag after completion of work.

- Frequency:

- Quarterly ± 7 days

- Check list for preventive maintenance:

- Check all the motors for proper connection and tighten the connections.

- Check all motors for abnormal noise/vibration replace the bearings if required.

- Check all mechanical parts for wear and tear.

- Check all interlocking for proper working.

- Check and ensure all safety parameters, interlocking.

- Check the packing belt, sensors, infeed conveyor, camera, ink jet machine for proper working.

- Check proper working of rejection valve.

- After preventive maintenance clean the equipment.

- After preventive maintenance take a trial for proper working of equipment.

- Preventive maintenance checklist and record for Ampoule Labeling Machine. SOP/EN/XXXYYY

- ABBREVIATIONS:

- CRF No. : Change Request Form number

- QA : Quality Assurance

- MMI : Man Machine Interface

- REFERENCES:

- Nil

- DISTRIBUTION LIST:

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES:

- Preventive maintenance checklist and record for Ampoule : SOP/EN/XXXYYY Labeling machine

SOP For Preventive Maintenance of Ampoule Labeling Machine

PREVENTIVE MAINTENANCE CHECKLIST & RECORD AMPOULE LABELING MACHINE

| Equipment Name | Location | ||

| Equipment ID | Frequency |

| Things to be done: | Check List | Remarks |

| Check all the motors proper connection and tighten the connections. | ||

| Check all motors for abnormal noise / vibration replace the bearings if required. | ||

| Check all mechanical parts for wear and tear. | ||

| Check all interlocking for proper working. | ||

| Check and ensure all safety parameters, interlocking. | ||

| Check the packing belt, sensors, infeed conveyor, camera and ink jet machine for proper working. | ||

| Check proper working of rejection valve. | ||

| Take a trial of proper working of the machine, after preventive maintenance. | ||

| Take a trial of proper working of machine, after preventive maintenance. | ||

| Record maintenance activity in log book record. |

Frequently Asked Questions:

What is the purpose of the SOP For Preventive Maintenance of Ampoule Labeling Machine ?

Answer: The purpose of this SOP is to outline the steps and guidelines for performing preventive maintenance on the Ampoule Labeling Machine to ensure its optimal performance, minimize downtime, and maintain accurate labeling of ampoules.

Who is responsible for carrying out the preventive maintenance activities as per the SOP For Preventive Maintenance of Ampoule Labeling Machine ?

Answer: The maintenance team is responsible for carrying out the preventive maintenance activities as per the SOP.

How often should preventive maintenance be performed on the Ampoule Labeling Machine?

- Answer: Preventive maintenance should be performed at regular intervals:

- Daily: Visual inspection, cleaning, and basic checks.

- Weekly: Lubrication and more thorough checks.

- Monthly: In-depth inspection and calibration, if required.

What materials and tools are required for the preventive maintenance of the Ampoule Labeling Machine?

Answer: The materials and tools required for preventive maintenance include:

- Clean lint-free cloths

- Isopropyl alcohol or approved cleaning solution

- Lubricants as recommended by the machine manufacturer

- Screwdrivers and wrenches (as applicable)

- Calibration equipment (if applicable)

What are the tasks involved in daily maintenance in the SOP For Preventive Maintenance of Ampoule Labeling Machine?

Answer: Daily maintenance tasks include:

- Visual inspection, cleaning, and basic checks of the machine’s exterior.

- Checking the label roll and ensuring it is loaded correctly.

- Inspecting the label dispenser and applicator mechanism.

- Running a quick test cycle to check basic functionality.

What should be done during weekly maintenance of the Ampoule Labeling Machine?

Answer: Weekly maintenance tasks include:

- Removing label residue or adhesive from the dispenser and applicator.

- Checking and adjusting the label alignment.

- Lubricating moving parts and inspecting conveyor belts and rollers.

- Verifying sensor performance and adjusting label roll tension.

What tasks are involved in monthly maintenance of the Ampoule Labeling Machine?

Answer: Monthly maintenance tasks include:

- Conducting an in-depth inspection of critical components like motors, belts, and gears.

- Calibrating the labeling system as per manufacturer’s guidelines.

- Inspecting the electrical control panel and reviewing maintenance records.

What documentation should be maintained in SOP For Preventive Maintenance of Ampoule Labeling Machine during preventive maintenance?

Answer: Documentation to be maintained includes:

- Maintenance log with date, time, tasks performed, and issues resolved.

- Records of spare parts used and their serial numbers, if applicable.

- Calibration results, if performed.

What safety precautions should be followed in SOP For Preventive Maintenance of Ampoule Labeling Machine ?

Answer: Safety precautions include:

- Powering off and disconnecting the machine before maintenance.

- Using appropriate personal protective equipment (PPE).

- Following lockout/tagout procedures when necessary.

- Complying with safety guidelines established by the company and the machine manufacturer.

Who should be trained on this SOP For Preventive Maintenance of Ampoule Labeling Machine ?

Answer: All personnel involved in operating, maintaining, or troubleshooting the Ampoule Labeling Machine should be trained on this SOP and related procedures.