Totalizers play a fundamental role in various fields, providing a means to aggregate and quantify data. From industrial applications to statistical analysis, these versatile devices are essential in measuring cumulative values. In this article, we will delve into the world of totalizers, understanding their purpose, functionality, and wide-ranging applications.

What are Totalizers?

Totalizers, also known as cumulative counters or summing devices, are mechanisms used to accumulate and display the sum of a series of values over time. They track and record data, adding each new value to the existing total, thus providing a running sum. Totalizers can be implemented both mechanically and electronically, with each type offering its unique advantages based on specific requirements.

Types of Totalizers

Totalizers are versatile devices used to accumulate and track cumulative values in different fields. They find applications in a wide range of industries, including manufacturing, data analysis, and resource management. In this article, we will explore various types of totalizers, each designed to suit specific requirements and provide valuable insights into cumulative data.

Mechanical Totalizers:

Mechanical totalizers utilize mechanical components, such as gears, levers, or rotating discs, to measure and accumulate values. These devices are often used in industrial settings where durability and reliability are paramount. Mechanical totalizers are known for their simplicity and resistance to harsh environmental conditions. They can be found in applications such as production monitoring, distance tracking, and revolutions counting.

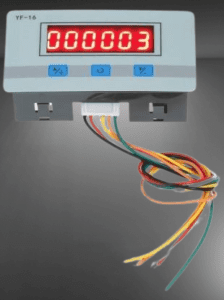

Electronic Totalizers:

Electronic totalizers have gained popularity with advancements in technology. These digital devices use integrated circuits, microcontrollers, or sensors to measure, calculate, and display cumulative values. Electronic totalizrs offer enhanced accuracy, flexibility, and programmability compared to their mechanical counterparts. They can be integrated into complex systems, enabling automation and data analysis. Electronic totalizrs find applications in areas such as energy monitoring, statistical analysis, and process control.

Digital Totalizers:

Digital totalizrs represent the latest evolution in totalizer technology. These devices utilize digital displays, often with numerical readouts or alphanumeric screens, to present cumulative values in a user-friendly manner. Digital totalizrs are commonly equipped with additional features, such as data logging, connectivity options, and advanced data visualization. They provide real-time insights and are widely used in applications that require quick and easy access to cumulative data, such as sports tracking, utility monitoring, and financial calculations.

Flow Totalizers:

Flow totalizrs are specialized totalizrs used to measure and accumulate fluid quantities, typically in liquid or gas form. They incorporate flow meters or sensors to monitor the flow rate and calculate the total volume or mass of the fluid passing through a system. Flow totalizrs are essential in industries like water management, energy monitoring, and chemical processing, where precise measurement and control of fluid flow are critical.

Statistical Totalizers:

Statistical totalizrs are designed specifically for data analysis and statistical applications. These totalizrs are equipped with features that enable the aggregation and calculation of data points, such as frequencies, averages, standard deviations, or other statistical measures. Statistical totalizrs find application in surveys, opinion polls, market research, and scientific studies, providing valuable insights into patterns, trends, and variations in data.

Programmable Totalizers:

Programmable totalizrs offer flexibility by allowing users to customize their functionality and parameters. These totalizrs can be programmed to perform specific calculations, accumulate values based on predefined conditions, or trigger alerts and actions. Programmable totalizrs are commonly used in industrial automation, quality control processes, and complex data analysis tasks, where the ability to tailor the device’s behavior to specific requirements is essential

Totalizers come in various forms to cater to different applications and industries. Mechanical totaliers excel in rugged environments, while electronic and digital totalizrs provide enhanced accuracy and flexibility. Flow totalizers specialize in measuring fluid quantities, while statistical and programmable totalizrs offer advanced data analysis capabilities. Understanding the different types of totalizrs allows for informed choices in selecting the most suitable device for specific needs, ensuring accurate tracking and analysis of cumulative values in diverse fields.

Applications of Totalizers

| Application | Description |

|---|---|

| Manufacturing and Production | Tracking quantities produced, raw material consumption, and machine uptime |

| Energy Monitoring | Measuring electricity, water, or gas consumption for billing and resource management |

| Statistical Analysis | Aggregating survey responses, calculating frequencies, and analyzing data |

| Utility Management | Monitoring water, electricity, or gas usage for efficient resource allocation |

| Sports and Fitness Tracking | Counting steps, laps, or distance traveled for personal fitness monitoring |

| Environmental Monitoring | Measuring water flows, air emissions, and fluid dynamics in ecological research |

| Agriculture and Irrigation | Monitoring water usage and irrigation efficiency for sustainable farming practices |

| Chemical Processing | Tracking volumes of chemicals used or produced for process control and optimization |

| Water Treatment and Distribution | Measuring water flow rates, ensuring efficient distribution and conservation |

| Financial Calculations | Accumulating financial transactions, calculating totals, and managing budgets |

Critical Components of the Totalizers

| Component | Description |

|---|---|

| Counter | The core component that tracks and accumulates values over time |

| Sensor | Detects and measures the input (e.g., fluid flow, electrical pulses) |

| Display | Shows the cumulative values in a user-readable format (e.g., numerical display, alphanumeric screen) |

| Input Interface | Allows users to input data or configure settings (e.g., buttons, keypad) |

| Control Circuit | Manages the operation and control of the totalizer, including data processing and calculations |

| Power Supply | Provides electrical power to the totalizer for its operation |

| Memory | Stores accumulated values or additional data for reference or analysis |

| Communication Interface | Enables data transfer to external systems or devices (e.g., USB, Ethernet, wireless) |

| Programming Interface | Allows for customization and configuration of the totalizer’s behavior and parameters |

| Housing/Casing | Encloses and protects the internal components of the totalizer |

Frequently Asked Questions

What is a totalizer?

Answer: A totalizer is a device used to accumulate and track cumulative values over time, such as volume, quantity, or count.

What are the types of totalizers based on their working principles?

Answer: Totalizrs can be mechanical, electronic, digital, or electromechanical, depending on the components and mechanisms used.

How do mechanical totalizers work?

Answer: Mechanical totalizrs utilize gears, rotating discs, or other mechanical components to physically count and accumulate values.

What are the advantages of electronic totalizers over mechanical ones?

Answer: Electronic totalizrs offer enhanced accuracy, programmability, integration capabilities, and the ability to process and analyze data.

What is the significance of flow totalizers?

Answer: Flow totalizrs are specialized totalizrs used to measure and accumulate fluid quantities, providing valuable data for process optimization, resource management, and control.

What are some common applications of totalizers in industrial settings?

Answer: Totalizrs are used for monitoring production quantities, machine uptime, equipment usage, and tracking material or fluid flow in industries such as manufacturing, chemical processing, and energy management.

How do digital totalizers differ from other types of totalizers?

Answer: Digital totalizrs utilize numerical or alphanumeric displays to present cumulative values, often with additional features like data logging, connectivity options, and advanced data visualization.

Can totalizers be customized or programmed for specific applications?

Answer: Yes, certain totalizrs, such as programmable totalizrs, can be customized or programmed to perform specific calculations, accumulate values based on predefined conditions, or trigger alerts and actions.

What are the key components of a totalizer?

Answer: The critical components of a totalizer typically include a counter, sensor, display, input interface, control circuit, power supply, memory, communication interface, programming interface, and housing/casing.

How do totalizers contribute to resource management and efficiency?

Answer: Totalizrs provide accurate tracking of quantities consumed or produced, helping in resource management, energy monitoring, water distribution, inventory control, and optimizing process efficiency.