Different types of Gears play a pivotal role in the mechanics of countless devices, transferring rotational force and enabling the smooth and efficient operation of machinery. These mechanical wonders come in various shapes and sizes, each designed to serve specific purposes and address unique engineering challenges. In this article, we delve into the intriguing world of gears, exploring their different types and shedding light on the mesmerizing mechanics that drive our modern world.

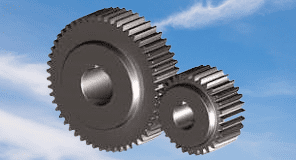

Spur Gears:

- Among the most common and straightforward types of gear are spur gears. These cylindrical gears feature straight teeth that run parallel to the gear axis. Spur gears are renowned for their simplicity, efficiency, and affordability. They find widespread use in applications where speed and power transmission are of utmost importance, such as automotive transmissions, industrial machinery, and household appliances.

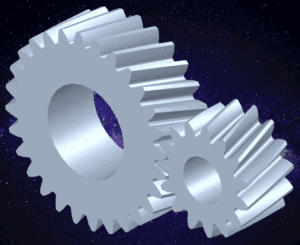

Helical Gears:

- Helical gears, with their angled teeth, offer a notable improvement over spur gears by providing smoother and quieter operation. The angled teeth enable gradual engagement and disengagement, minimizing noise and vibration. Helical gears excel in applications that require high speed, high-load capacity, and precision motion control. They are commonly found in automotive transmissions, machine tools, and heavy-duty equipment this is the types of Gears.

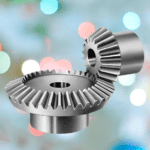

Bevel Gears:

- Bevel gears possess conical-shaped teeth and are used to transfer motion between intersecting shafts. These gears allow for a change in direction and angle of transmission, making them ideal for applications where the input and output shafts are not parallel. Bevel gears are commonly employed in differential gears, hand drills, printing presses, and marine propulsion systems this is the types of Gears.

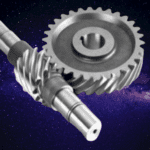

Worm Gears:

- Worm gears consist of a cylindrical gear (worm) and a toothed wheel (worm wheel). They are primarily used to achieve a high gear ratio while transmitting motion between non-parallel, perpendicular shafts. Worm gears offer excellent load-carrying capacity, self-locking capabilities, and high efficiency. These attributes make them indispensable in applications like conveyor systems, elevators, and heavy machinery.

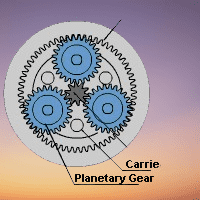

Planetary Gears:

- Planetary gears, also known as epicyclic gears, utilize a system of gears arranged around a central gear, similar to planets orbiting a sun. This arrangement allows for multiple gear ratios and torque variations. Planetary gears offer high power density, compact size, and exceptional efficiency. They are extensively used in automotive transmissions, robotics, and aerospace applications.

Conclusion: Gears come in a diverse range of types of gears, each carefully designed to meet specific mechanical requirements. From the simplicity of spur gears to the versatility of planetary gears, these mechanical marvels drive the wheels of innovation across industries. Understanding the various types of gears and their applications enables engineers and enthusiasts to harness their power effectively. As technology continues to advance, gears will remain an integral part of our ever-evolving world, facilitating motion and propelling us into the future.

Applications of the Types of Gears.

| Gear Type | Applications |

|---|---|

| Spur Gears | Automotive transmissions, industrial machinery, |

| household appliances | |

| Helical Gears | Automotive transmissions, machine tools, |

| heavy-duty equipment like RMG and Compression Machine | |

| Bevel Gears | Differential gears, hand drills, printing presses, |

| marine propulsion systems | |

| Worm Gears | Conveyor systems, elevators, heavy machinery |

| Planetary Gears | Automotive transmissions, robotics, aerospace applications |

How many types of gears

There are several types of gears commonly used in mechanical systems. Here are the main types of gears:

- Spur Gears: These gears have straight teeth and are mounted on parallel shafts. They are the most common and straightforward type of gear.

- Helical Gears: Similar to spur gears, helical gears have angled teeth that create a helix shape. This design allows for smoother and quieter operation.

- Bevel Gears: Bevel gears have teeth that are cut on conical surfaces and are used to transfer motion between intersecting shafts.

- Worm Gears: Worm gears consist of a worm (a cylindrical gear) and a worm wheel. They are used to transmit motion between non-parallel, perpendicular shafts and provide high gear ratios.

- Planetary Gears: Also known as epicyclic gears, planetary gears consist of multiple gears arranged around a central gear. They offer versatility in terms of gear ratios and torque variations.

- Rack and Pinion Gears: This gear system consists of a linear gear (rack) and a circular gear (pinion) that meshes with it. It is commonly used in applications requiring linear motion, such as steering systems.

- Hypoid Gears: Hypoid gears are similar to bevel gears but have offset axes. They are often used in automotive applications, such as rear-wheel drive systems.

- Spur Rack Gears: Spur rack gears are straight gears with teeth cut in a straight line along a flat surface. They are used in applications requiring linear motion, such as CNC machines.

These are the main types of gears commonly encountered in mechanical systems, each with its own unique characteristics and applications.

Frequently Asked Questions about types of Gears

What are spur gears?

Answer: Spur gears are cylindrical gears with straight teeth that run parallel to the gear axis.

What is the advantage of helical gears over spur gears?

Answer: Helical gears provide smoother and quieter operation due to their angled teeth, which allow for gradual engagement and disengagement.

Where are bevel gears commonly used?

Answer: Bevel gears are used to transfer motion between intersecting shafts, making them suitable for applications where the input and output shafts are not parallel.

What are the characteristics of worm gears?

Answer: Worm gears have a cylindrical gear (worm) that meshes with a toothed wheel (worm wheel), providing a high gear ratio and self-locking capabilities.

In which applications are planetary gears commonly found?

Answer: Planetary gears are extensively used in automotive transmissions, robotics, and aerospace applications due to their high power density and versatility in gear ratios.

What is the purpose of rack and pinion gears?

Answer: Rack and pinion gears are used for linear motion applications, such as in steering systems, where the pinion gear meshes with a linear gear (rack).

How do hypoid gears differ from bevel gears?

Answer: Hypoid gears are similar to bevel gears but have offset axes, allowing for more compact designs and efficient power transmission.

What is the main advantage of spur rack gears?

Answer: Spur rack gears are used for linear motion and provide a simple and efficient means of converting rotational motion into linear motion.

What are the primary applications of spur gears?

Answer: Spur gears find widespread use in automotive transmissions, industrial machinery, and household appliances is one of the types of Gears.

How are helical gears beneficial in machine tools?

Answer: Helical gears are advantageous in machine tools because they offer high-speed operation, high-load capacity, and precise motion control.

Where are worm gears commonly used?

Answer: Worm gears are commonly employed in conveyor systems, elevators, and heavy machinery due to their excellent load-carrying capacity and self-locking properties.

What is the significance of bevel gears in differential gears?

Answer: Bevel gears play a crucial role in differential gears, enabling the smooth distribution of torque between the wheels of a vehicle.

What makes planetary gears suitable for aerospace applications?

Answer: Planetary gears are compact, efficient, and provide multiple gear ratios, making them ideal for space-constrained aerospace applications.

How do spur gears contribute to household appliances?

Answer: Spur gears are often used in household appliances like washing machines and blenders to transmit power and achieve different speeds for various functions.

What advantages do helical gears offer in heavy-duty equipment?

Answer: Helical gears can handle high loads and provide smooth operation, making them suitable for heavy-duty equipment such as construction machinery and mining equipment.

Good Laboratory Practices (GLP)

For more queries related to types of Gears you may contact us at: flairpharma28@gmail.com

Good information