Various batch coding machines are needed by different businesses in order to print codes and data on a variety of products and packaging. In this article, we’ll walk you through the specifics of two different technologies to help you understand how industrial batch coding machines function and where they’re used. Equipment that performs batch coding is known as a batch code number. Batch coding is the process of writing codes that imply the manufacturing dates, expiry dates, batch numbers, etc. in the form of numbers and letters.

When connecting product concerns to the production plant, batch numbers are crucial to the manufacturing facility. Product batch numbers can be found either printed on the can itself or on a small, white label with gum on the can lid and occasionally on the package.

A product batch code, which is a combination of numbers and/or letters that is used to identify a group of identical mass-produced products, is also known as a lot number, lot code, or code number. These similar traits could consist of the Date and time of creation.

Working Principle:

Beams or spray are used by batch coding devices to mark the goods. Ink is sprayed from the Inkjet printer while laser marking equipment emits beams. The machine or product is placed on conveyor belts, which must move continuously. With a sensor, the moving product is detected.

- Laser Marking

Data is marked on a product surface via laser marking, which uses a tightly focused light beam. This narrowly focused beam of light provides an easily readable piece of precise and accurate information by focusing on a particular portion of the product’s surface.

The following three methods are available for laser marking:

- LaserAnnealing

One of the unpopular batch coding techniques, laser annealing involves heating a metallic product to alter its color. The batch codes are represented by this color change. It is more widely used as a marking procedure, though.

- Laser Engraving

Using a laser beam from a laser marking machine to vaporize portions of a material’s surface in order to inscribe deep and permanent marks, or information on the product, is known as laser engraving. Batch codes from laser engraving are quite readable.

- Laser Etching

In order to engrave batch information on the goods, a surface is heated using a laser.

The advantages of laser marking include increased productivity, reduced waste, increased visibility and accountability throughout the manufacturing and distribution chains, significant cost reductions without sacrificing quality, and the ability to mark a variety of materials including ceramic, plastic, glass, wood, paper, steel, titanium, aluminum, copper, and cardboard.

- Thermal Ink-jet Printing

A thermal inkjet printer or a thermal foaming inkjet printer is used in the thermal inkjet printing process to mark the data on a product. The ink used in the thermal inkjet printer is heated before printing.

Because of the following benefits, thermal inkjet printing is a preferred method for batch coding: The thermal inkjet printers come with sealed cartridges that ensure no leakage, thereby improving user control; Thermal inkjet printing is economical because the printers require little maintenance; Thermal printing can support a high volume of paper print for batch coding.

Several completely automatic and semi-automatic devices also print information on products using heat rather than ink or hot stamps, but they nonetheless operate on the same principles as thermal printing machines.

Example: The six-character batch code includes the Julian Date, the last digit of the manufacturing year, the production line, and the shift. The thirty-sixth day of the year, in this case, February 5, is represented by the number.

Type of Batch Coding Machine:

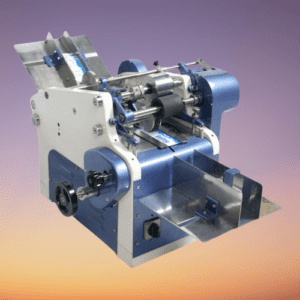

The Manual Coding Machine

The method of operation for a manual batch coding machine is by hand. This makes it appropriate for little packaging or small firms, and small producers use it. Its manufacturing capacity is reduced because it is a manually operated machine. Traditional hot stamps and convenient coder machines are two examples

The Semi-Automatic Batch Coding Machine

Machines for semi-automated batch coding can do manual and automatic tasks. Applying codes is an example of an automatic attribute, whereas feeding and collecting products is an example of a manual characteristic.

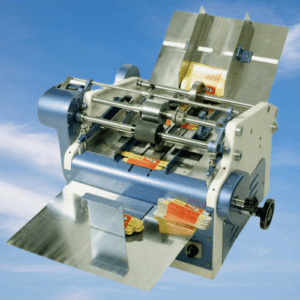

Fully Automatic Batch Coding Machine

Machines that perform automatic batch coding can operate without any help from a person. Every process step is mechanized and under control, from feeding the product to collecting it. This procedure continues until the product or code has to be changed.

Large-scale production is best suited to an automatic batch coding machine.

Major Component of Batch Coding Machine:

- Color Ribbon Roll.

- Thermal Transfer Ribbon.

- Letter Holder.

- Hot Foil Ribbon.

- V Belt Timing Belt.

- Printer

Validation and documentation:

Complete documentation and certification traceable to national and international standards:

- MOC / COA certificate of contact and noncontact PARTS.

- MOC food grade and nontoxic certificates of contact and noncontact gaskets

- Calibration certificates of gauges and instruments with traceability certificate

- Operational manual of automated or PLC system / MMI

- Operational & maintenance manuals for the coater.

- Maintenance Manual

- FAT / SAT document

- GA (General alignment) drawing

- Alarm list (diagnostic and system created)

- FAT and installation qualification protocol

- PLC backup

- Complete set of DQ, and IQ Documents.

- All documents are as per URS

Manufactures Company in India:

- Royal Pack Industries.

- Industrial Inkjet.

- Docod Precision Group Co. Ltd.

Royal Pack Industries.

Frequently Asked Questions for batch coding machine:

What is the use of a batch coding machine?

Answer: Batch Coding machines are used to print Batch Numbers, Manufacturing Dates, Expiry Dates, MRP, and other such details which give detailed information about the product.

How do batch coding?

Answer: Using the production date as the batch number’s base is an easy technique to produce batch numbers for manufacturing. For any additional information, you can then add a numerical code to the product package. You can increase the batch number, for instance, if you bake a batch of cupcakes twice a day.

How does a coding machine work?

Answer: Batch Coding machines use beams/spray to mark the product. Beams emanate from the laser marking machine while the ink is sprayed from the Inkjet printer. The product or machine is placed on conveyor belts which should constantly be moving. The moving product is sensed by a sensor.

Where is batch code written?

Answer: When connecting product concerns to the production plant, batch numbers are crucial to the manufacturing facility. Product batch numbers can be found either printed on the can itself or on a small, white label with gum on the can lid and occasionally on the package.

Where is batch code?

Answer: Manufacturers and suppliers can identify the batch in which the product was created using the batch code. Typically, the container’s bottom is where the code is printed. The batch code is located at the top of tube-shaped items, where the product is sealed.

What are examples of machine coding?

Answer: An example of a machine coding problem could be designing a snake and ladder game with certain requirements and constraints. This is generally followed by a code review process where an interviewer goes through the code and tries to understand the design decisions.