A chiller, an embodiment of cooling ingenuity, is a mechanical marvel that stands as a cornerstone of modern temperature control. This intricate apparatus orchestrates a symphony of thermodynamics, harnessing the laws of physics to deliver efficient and precise cooling solutions across diverse applications.

At its essence, a chiller is a system designed to extract heat from a space, substance, or process, consequently lowering its temperature. It achieves this feat through the judicious manipulation of refrigerants—fluids that transition between liquid and vapor states at varying temperatures and pressures. The chiller’s operation is underpinned by a cyclical dance of processes, each stage contributing to the larger narrative of cooling mastery.

Working principle of the chiller

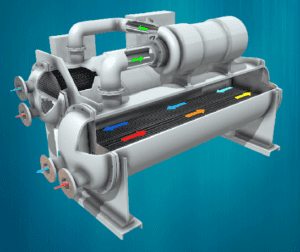

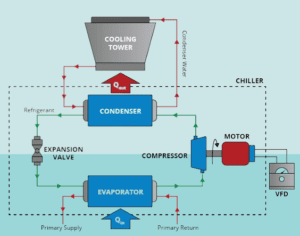

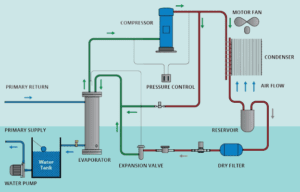

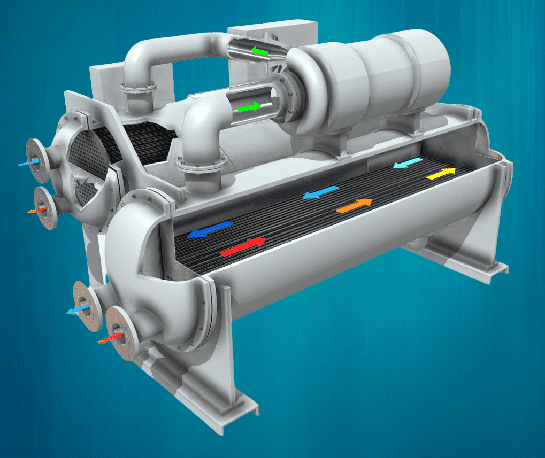

The working principle of a chiller is based on the refrigeration cycle. At its core, a chiller functions as a heat exchanger, transferring thermal energy from one medium to another. The chiller cycle is a cyclic journey that encompasses various stages, each contributing to the overall cooling process:

- Evaporation: The cycle commences with the evaporation of a refrigerant, a substance with a low boiling point. In the evaporator, heat from the surroundings is absorbed by the refrigerant, causing it to transition from a liquid to a vapor state. This phase change is fundamental to the cooling process, as it extracts heat from the environment.

- Compression: The vaporized refrigerant, now laden with absorbed heat, is drawn into the compressor. Here, the vapor is compressed, increasing both its temperature and pressure. This process demands energy input, typically provided by an electric motor or a combustion engine. The compressed vapor emerges as a high-pressure, high-temperature gas.

- Condensation: The pressurized vapor then enters the condenser, where it relinquishes the heat it acquired during compression. Through contact with a cooling medium—often air or water—the refrigerant releases its thermal energy. As a result, the vapor condenses back into a liquid state, marking the completion of its thermal journey.

- Expansion: The condensed liquid, now at high pressure, passes through an expansion valve. This valve facilitates a rapid reduction in pressure, causing the refrigerant to expand and partially evaporate. This expansion-induced cooling prepares the refrigerant to reenter the evaporator and repeat the cycle.

The chiller’s working principle is rooted in the laws of thermodynamics, particularly the principles of phase change, heat transfer, and pressure dynamics. By skillfully manipulating these principles, chiller systems achieve controlled cooling for a wide range of applications.

Types of the Chillers

Cooling technology, a diverse array of chillers emerges, each a unique embodiment of engineering innovation tailored to specific needs and environments. These chiller types, like distinct notes in a harmonious composition, cater to a spectrum of cooling demands, showcasing the versatility of thermal mastery.

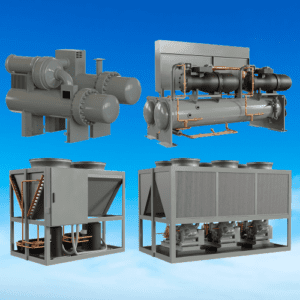

- Centrifugal Chillers: A pinnacle of mechanical prowess, centrifugal chillers harness the centrifugal force to facilitate cooling. The core of their operation lies within the compressor, where the kinetic energy of the vapor is converted into pressure, leading to the release of heat. These chillers excel in large-scale applications, providing robust cooling capabilities for expansive spaces.

- Reciprocating Chillers: Embracing the rhythm of reciprocation, these chillers operate using pistons that draw in refrigerant and compress it through alternating movements. They are known for their efficiency in handling varying load demands and are often preferred for their adaptability in industrial and commercial settings.

- Scroll Chillers: Scroll chillers harmonize simplicity and efficiency. Their operation involves two interlocked scroll-like components that create a gradual compression process. With fewer moving parts, these chillers are celebrated for their reliability, making them suitable for diverse cooling scenarios.

- Absorption Chillers: Unveiling a chemical duet, absorption chillers utilize a heat source, such as natural gas or waste heat, to drive the refrigeration cycle. This innovative approach makes them an energy-efficient choice for applications where waste heat is readily available, such as industrial processes or co-generation plants.

- Screw Chillers: Employing the principle of helical compression, screw chillers craft cooling through a rotating helical screw and a stationary component. This design bestows robustness and energy efficiency, rendering screw chillers suitable for both industrial and commercial cooling requirements.

- Air-Cooled Chillers: Redefining cooling dynamics, air-cooled chillers embrace the ambient air to dissipate heat, eliminating the need for water cooling infrastructure. These chillers are well-suited for environments where water availability is restricted or where simplicity and cost-effectiveness are paramount.

- Water-Cooled Chillers: Engaging the fluidity of water, water-cooled chillers channel heat away through water-based systems. They excel in scenarios requiring consistent cooling, making them a staple in applications ranging from data centers to industrial processes.

- Portable Chillers: A testament to adaptability, portable chillers are designed for on-the-go cooling needs. They can be effortlessly moved to cater to changing requirements, making them a favored choice for applications with fluid demands.

- Geothermal Chillers: Capitalizing on the Earth’s stable temperature, geothermal chillers leverage subterranean heat exchange to facilitate cooling. This sustainable approach offers energy savings and environmental benefits, making it an attractive option for eco-conscious applications.

- Hybrid Chillers: Blurring the lines of innovation, hybrid chillers combine two or more cooling technologies to optimize efficiency and performance. By synergizing the strengths of different methods, hybrid chillers deliver adaptive cooling solutions for complex demands.

Critical Parameters of the Chillers Machine

- Coefficient of Performance (COP): This essential parameter quantifies the efficiency of a chiller by comparing the amount of cooling produced (refrigeration effect) to the energy input (electric power consumed). The formula for COP is:

COP=Refrigeration Effect / Electric Power Input

- Ton of Refrigeration (TR): A traditional unit of cooling capacity, a ton of refrigeration represents the amount of heat that is removed to create one ton of ice in 24 hours. It’s often used as a reference to chiller sizing.

- Chilled Water Flow Rate (GPM): The rate at which chilled water circulates through the chiller system, influencing the heat transfer process and overall cooling capacity.

- Chilled Water Temperature Difference (ΔT): The temperature difference between the inlet and outlet of the chilled water, affecting the amount of heat transferred. The formula for heat transfer rate (Q) using temperature difference is:

Q=Flow Rate×Specific Heat×ΔT

- Evaporator Approach (EA): This parameter indicates the difference between the leaving chilled water temperature and the saturated evaporator temperature.

- Condenser Approach (CA): Similar to the evaporator approach, this parameter reflects the difference between the leaving condenser water temperature and the saturated condenser temperature.

- Refrigerant Mass Flow Rate (ṁ): The mass of refrigerant passing through the chiller per unit of time, influencing the heat transfer capacity and system performance.

- Refrigerant Pressure Ratio (PR): The ratio of the high-side pressure to the low-side pressure of the refrigerant, providing insight into the efficiency and compression process of the chiller.

- Refrigerant Enthalpy: A measure of the internal energy of the refrigerant, including both sensible and latent heat components. It’s crucial for analyzing the heat transfer processes in the evaporator and condenser.

Types of the refrigeration Cycles

- Vapor Compression Refrigeration Cycle: This archetype of refrigeration cycles is ubiquitous in various cooling applications. It involves four essential stages: compression, condensation, expansion, and evaporation. The cycle begins with the compression of a vaporized refrigerant, followed by condensation in a condenser, expansion through an expansion valve, and evaporation in an evaporator. The cycle relies on the refrigerant’s phase changes and compression to achieve cooling. Its adaptability and efficiency have solidified its place in air conditioning, refrigeration, and industrial processes.

- Absorption Refrigeration Cycle: Departing from mechanical compression, this cycle relies on absorption and desorption processes to achieve cooling. It involves a working fluid that is absorbed into a solution, then desorbed through heat input. This cycle is well-suited for situations where waste heat or other low-grade heat sources are available, making it an energy-efficient choice for specific applications.

- Gas Refrigeration Cycle: Different from vapor cycles, gas refrigeration cycles employ gases instead of liquids as the working fluids. These cycles often use air as the refrigerant, making them suitable for applications where liquids might not be feasible. Gas refrigeration cycles are commonly used in industrial processes, such as natural gas liquefaction.

- Thermoelectric Refrigeration Cycle: Unique in its approach, this cycle utilizes the Seebeck effect, where a voltage difference across two dissimilar materials generates a temperature difference. It’s employed in solid-state thermoelectric devices that can provide localized cooling, making it useful for electronics cooling and other specialized applications.

- Steam Jet Refrigeration Cycle: This cycle capitalizes on the expansion of high-pressure steam to produce a vacuum, which is then used to evaporate the refrigerant in an evaporator. It’s an efficient cycle for large-scale refrigeration and air conditioning systems.

- Cascade Refrigeration Cycle: This sophisticated cycle involves two or more separate refrigeration cycles with different refrigerants, each operating at different temperature levels. The lower-temperature cycle cools the condenser of the higher-temperature cycle, leading to an extended temperature range and enhanced efficiency. Cascade cycles are used in ultra-low temperature applications and in scenarios where a single refrigerant isn’t suitable for the entire temperature range.

- Ejector Refrigeration Cycle: In this cycle, an ejector is used to create a pressure difference between the evaporator and the condenser, aiding in the circulation of refrigerant. It’s an energy-efficient solution for certain cooling requirements.

Applications of the chiller plant

| Industry/Application | Chiller Usage |

|---|---|

| Commercial Buildings | Air conditioning and climate control |

| Data Centers | Cooling server rooms and IT equipment |

| Industrial Processes | Cooling machinery, equipment, and processes |

| Pharmaceuticals | Temperature-controlled storage and production |

| Food and Beverage | Cooling during production, storage, and packaging |

| Hospitals and Healthcare | Medical equipment cooling and air conditioning |

| Chemical Manufacturing | Process cooling for chemical reactions |

| Plastics Manufacturing | Cooling plastic molds and machinery |

| Printing and Publishing | Cooling printing presses and paper handling |

| Agriculture | Greenhouse climate control and food storage |

| Breweries and Wineries | Temperature control during fermentation |

| Automotive | Cooling production lines and testing facilities |

| Aerospace | Temperature control in clean rooms and labs |

| Research Laboratories | Cooling sensitive experiments and equipment |

| Energy Generation | Cooling equipment in power plants and generators |

| Entertainment Venues | Cooling theaters, auditoriums, and performance areas |

Frequently Asked Questions:

What is a chiller?

Answer: A chiller is a mechanical system designed to remove heat from a space, substance, or process, thereby lowering its temperature. It achieves this through the cyclic manipulation of refrigerants and thermodynamic processes.

How does a chiller work?

Answer: A chiller operates on the principle of vapor compression. It involves four main stages: compression, condensation, expansion, and evaporation. The refrigerant transitions between liquid and vapor states, absorbing and releasing heat to achieve cooling.

What are the primary components of a chiller?

Answer: The main components are the evaporator, compressor, condenser, and expansion valve. These work in synergy to facilitate heat transfer and cooling.

What is the Coefficient of Performance (COP) of a chiller?

Answer: COP is a measure of a chiller’s efficiency, calculated by dividing the heat removed (refrigeration effect) by the energy input (electric power). A higher COP indicates better efficiency.

What are the types of chillers?

Answer: Chillers come in various types, including air-cooled chillers, water-cooled chillers, centrifugal chillers, absorption chillers, and more, each suited to specific applications and requirements.

What are some common applications of chillers?

Answer: Chillers find use in air conditioning for commercial buildings, cooling data centers, industrial processes, food storage, pharmaceutical production, hospitals, and more.

How does an absorption chiller differ from a vapor compression chiller?

Answer: Unlike vapor compression chillers that use mechanical compression, absorption chillers rely on heat input to drive the refrigeration cycle, making them energy-efficient when waste heat is available.

What is the purpose of the expansion valve in a chiller?

Answer: The expansion valve reduces the pressure of the refrigerant after it exits the condenser, causing it to expand and partially evaporate, which generates cooling.

How does a chiller achieve temperature control in industrial processes?

Answer: By manipulating the flow rate, temperature, and pressure of the refrigerant, a chiller can provide precise cooling to industrial machinery, ensuring optimal process conditions.

What is the significance of subcooling and superheat in the chiller cycle?

Answer: Subcooling ensures that the refrigerant entering the expansion valve is entirely liquid, while superheat ensures that the refrigerant entering the compressor is fully vaporized, both contributing to the efficiency and stability of the cycle.

What is the role of a chiller in data centers?

Answer: Chillers are crucial for cooling data centers, as they regulate the temperature of server rooms, preventing overheating and maintaining optimal operating conditions for IT equipment.

How do chillers contribute to energy efficiency?

Answer: Chillers can incorporate energy-saving features such as variable-speed compressors and intelligent control systems, which optimize performance based on demand, leading to reduced energy consumption.

How are chillers selected for specific applications?

Answer: Chiller selection involves considering factors like cooling capacity, temperature requirements, efficiency goals, available energy sources, and environmental conditions.

Can chillers be used for heating as well?

Answer: Some chiller systems can be equipped with reversible heat pumps that allow them to provide both cooling and heating by reversing the refrigeration cycle.

What role does a chiller play in the food and beverage industry?

Answer: Chillers are used for cooling during production, storage, and packaging processes, ensuring the quality and safety of food and beverages.

very good information about chiller working principles. thanks for great information

“Does the refrigeration cycle in split air conditioners follow the same principles? Thank you for your excellent article.”