Mobile Laminar Air Flow (LAF) systems provide portable and flexible solutions for creating controlled and sterile environments in various industries. These self-contained units, equipped with HEPA filters and airflow control mechanisms, offer easy mobility and positioning. Ideal for temporary cleanrooms, field operations, or supplemental clean zones, mobile LAF units ensure clean airflow for activities such as sample preparation and small-scale manufacturing. Their versatility and ease of installation make them valuable in pharmaceuticals, healthcare, research laboratories, and electronics manufacturing. With a focus on maintaining air quality and preventing contamination, mobile LAF systems offer a practical solution for on-the-go clean environments.

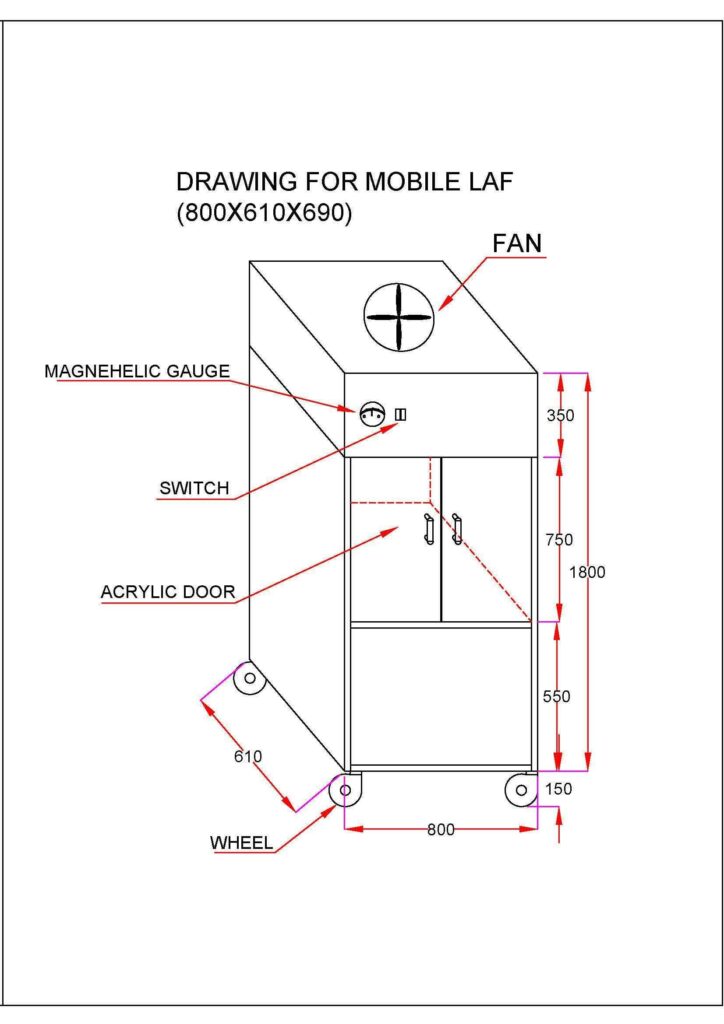

Mobile Laminar Air Flow (LAF) Drawing

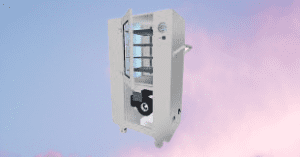

Mobile Laminar Air Flow (LAF) units are typically self-contained and equipped with filtration systems, blowers, and airflow control mechanisms. They are compact and often come with wheels or casters, allowing for easy mobility and flexibility in positioning.

These units employ the same principles as traditional LAF systems, including the use of HEPA filters to remove contaminants and the establishment of a unidirectional airflow pattern. They create a clean zone or work area where air quality is maintained, suitable for activities such as sample preparation, small-scale manufacturing, or other processes requiring a controlled environment.

Mobile Laminar Air Flow (LAF) units find applications in various industries, including pharmaceuticals, healthcare, research laboratories, and electronics manufacturing. They can be used in temporary cleanrooms, field operations, or as supplementary systems in existing facilities to expand clean areas as needed.

The advantages of Mobile Laminar Air Flow (LAF) units include their versatility, ease of installation, and the ability to provide localized clean zones where necessary. However, it is important to ensure that mobile units meet the required standards and are properly maintained to ensure optimal performance and adherence to regulatory requirements.

Working principle of a Mobile Laminar Air Flow (LAF)

The working principle of a Mobile Laminar Air Flow (LAF) system is based on the same principles as traditional LAF systems. It involves creating a controlled and sterile airflow pattern to maintain a clean environment within a portable unit. Here’s a breakdown of the working principle:

- Air Filtration: Mobile Laminar Air Flow (LAF) units have high-efficiency particulate air (HEPA) filters. These filters are designed to capture and remove airborne particles, including dust, microbes, and allergens, ensuring a clean and sterile airflow.

- The blower or Fan Unit: The Mobile Laminar Air Flow (LAF) system incorporates a blower or fan unit responsible for drawing in ambient air. The fan creates the airflow necessary for the LAF system and ensures a consistent velocity of air movement.

- Airflow Control: Mobile Laminar Air Flow (LAF) systems employ adjustable vents or perforations to direct the airflow in a unidirectional pattern. This ensures that the air moves in a straight path without turbulence or mixing, maintaining the cleanliness of the designated work area.

- Portability and Mobility: Mobile Laminar Air Flow (LAF) units are designed to be portable, typically with wheels or casters for easy movement. They can be positioned in different locations, providing flexibility in creating clean zones wherever required.

- Self-Contained System: Mobile Laminar Air Flow (LAF) systems are self-contained, meaning they integrate all the necessary components within the unit. This includes the filtration system, fan, controls, and monitoring devices, allowing for a compact and independent setup.

The working principle of a Mobile Laminar Air Flow (LAF) system aims to create a clean and sterile environment in a portable unit, suitable for temporary cleanrooms, field operations, or supplemental clean zones. By utilizing filtration, airflow control, and portability, these systems provide flexibility and mobility while ensuring controlled air quality and contamination prevention.

Applications of Mobile Laminar Air Flow (LAF) systems

Mobile Laminar Air Flow (LAF) systems offer several applications in the pharmaceutical industry, providing portable clean environments where needed. Here are some common applications:

- Mobile Compounding: Mobile Laminar Air Flow (LAF) units are used for the sterile compounding of medications in various healthcare settings, including hospitals, clinics, and home healthcare. They ensure a clean and controlled environment for preparing sterile preparations, such as intravenous medications or customized dosage forms.

- Field Sampling and Testing: Mobile Laminar Air Flow (LAF) systems are valuable for on-site sampling and testing in pharmaceutical manufacturing or environmental monitoring. They provide a clean zone for collecting samples and conducting microbial or particulate testing, ensuring accurate results without the need for a dedicated laboratory.

- Mobile Cleanrooms: Mobile Laminar Air Flow (LAF) units are utilized to create temporary cleanrooms in scenarios where a dedicated cleanroom is not available or practical. These units can be deployed during pharmaceutical production or research activities, providing a sterile environment for critical processes.

- Research and Development: systems are used in pharmaceutical research and development laboratories, enabling researchers to create controlled and sterile environments for experiments, formulation development, and sample preparation, regardless of the location.

- Emergency Response and Disaster Relief: During emergencies or natural disasters, mobile LAF units can be deployed to provide clean environments for pharmaceutical storage, medication compounding, or medical procedures, ensuring safe and sterile conditions in challenging situations.

- Mobile Vaccine Administration: Mobile LAF systems are utilized in mobile vaccination clinics or campaigns, providing a controlled and sterile environment for vaccine administration. They help ensure the safety and efficacy of vaccine delivery in various locations.

- Point-of-Care Testing: Mobile LAF units are employed in point-of-care testing settings, such as mobile healthcare units or remote clinics. They create a clean zone for conducting diagnostic tests, preventing contamination, and maintaining accuracy.

- Clean Transportation: Mobile LAF systems can be integrated into transport vehicles or containers used for the distribution of pharmaceutical products. They help maintain a controlled environment during transit, safeguarding the integrity and quality of sensitive medications.

Manufacturers of Mobile Laminar Air Flow (LAF)

The reputable manufacturers in India known for their expertise in producing Mobile Laminar Air Flow (LAF) systems:

- Esco Healthcare

- NuAire

- Labconco

- Mystaire

- Athena Technology

- Weiber

- The Bombay Engineering Works

- Biosafety Technologies Pvt. Ltd.

- Asico India

- Clean Air Systems

Price of Mobile Laminar Air Flow (LAF)

The price of Mobile Laminar Air Flow (LAF) systems can vary significantly based on factors such as brand, specifications, features, and additional customization options. Prices can also differ between India and other countries due to variations in manufacturing costs, import/export duties, and market dynamics.

In India, the price range for Mobile LAF systems typically starts from around INR 50,000 and can go up to several lakhs or more, depending on the specific requirements and complexity of the unit.

On a global scale, Mobile LAF systems can range from a few hundred dollars for basic models to several thousand dollars or more for advanced and larger units. High-end or customized Mobile LAF systems with additional features can be even more expensive.

It’s important to note that the prices mentioned here are rough estimates, and actual prices may vary. It’s recommended to contact manufacturers or suppliers directly for accurate and up-to-date pricing information based on your specific needs and location.

Frequently Asked Questions:

What is a Mobile Laminar Air Flow (LAF) system?

Answer: A Mobile LAF system is a portable unit designed to provide a controlled and sterile environment in various locations where a permanent installation may not be feasible or necessary.

How does a Mobile LAF system differ from a traditional LAF system?

Answer: Mobile LAF systems offer portability and mobility, allowing them to be easily moved and positioned in different locations as needed, while traditional LAF systems are typically fixed installations.

What are the main components of a Mobile LAF system?

Answer: The main components of a Mobile LAF system typically include a fan or blower unit, HEPA filters, adjustable vents or perforations for airflow control, and a self-contained design for portability.

What are the applications of Mobile LAF systems in the pharmaceutical industry?

Answer: Mobile LAF systems find applications in sterile compounding, field sampling and testing, temporary cleanrooms, research and development, emergency response, mobile vaccine administration, point-of-care testing, clean transportation, and more.

How are Mobile LAF systems powered?

Answer: Mobile LAF systems are typically powered by electricity, and some models may have battery options for temporary use in areas without access to power sources.

Are Mobile LAF systems as effective as traditional LAF systems?

Answer: Mobile LAF systems utilize similar principles as traditional Mobile Laminar Air Flow (LAF) systems and can provide effective control of airborne contaminants when properly maintained and operated according to guidelines.

What is the recommended airflow velocity in a Mobile LAF system?

Answer: The recommended airflow velocity in a Mobile Laminar Air Flow (LAF) is generally similar to traditional LAF systems, typically between 0.36-0.54 m/s (70-100 ft/min) for efficient particle control.

How often should the filters be replaced in a Mobile LAF system?

Answer: The frequency of filter replacement in a Mobile Laminar Air Flow (LAF) system depends on factors such as usage, environmental conditions, and manufacturer recommendations. Filters are typically replaced every 6 to 12 months.

Are Mobile LAF systems compliant with regulatory standards?

Answer: Mobile Laminar Air Flow (LAF) systems should meet relevant regulatory standards and guidelines for air quality control and contamination prevention. Compliance depends on the design, filtration efficiency, and proper maintenance of the system.

Can Mobile LAF systems be customized to specific requirements?

Answer: Yes, Mobile Laminar Air Flow (LAF) systems can be customized to meet specific requirements, including size, airflow control, additional features, and integration with other equipment, depending on the manufacturer’s capabilities.

We are looking for mobile LAF for packaging material sampling purpose please provide me models and quotation for above LAF.