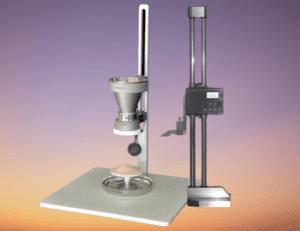

In industries where powdered materials are integral to the manufacturing process, understanding powder flow behavior is crucial. The Powder Flow Tester is an advanced instrument designed to measure and analyze the flow properties of powders, ensuring consistent quality and optimal performance. This guide explores the working principles, applications, advantages, and disadvantages of the Powder Flow Tester, along with answers to frequently asked questions.

Working Principle of the Powder Flow Tester:

The Powder Flow Tester operates on a sophisticated yet straightforward principle of measuring axial force, time, and distance as the powder undergoes various controlled flow operations. Here’s a detailed look into its working principle:

- Conditioning the Powder Column:

- The process begins with conditioning the powder column to eliminate variations caused by different operators. This step ensures the consistency and reliability of the test results.

- Real-Time Data Collection:

- A sensitive transducer measures axial force, time, and distance during the test. The data is displayed and analyzed in real-time using Exponent software, providing immediate insights into the powder’s behavior.

- Controlled Flow Displacement:

- The powder column can be displaced in multiple ways by programming the rotation of the blade. Variables such as path angle, blade direction, and tip speed are adjusted to suit the process and measurement requirements.

- Patented Helical Blade:

- The precision-engineered helical blade, made using Selective Laser Sintering, ensures minimal disturbance as it cuts through the powder column. This unique design negates the need for complex torque measuring systems and achieves highly reproducible results.

Controlled Flow Operations:

The Powder Flow Tester performs various controlled flow operations to measure different powder properties. These operations include:

- Lifting/Aerating:

- Conditions the powder column and measures particle cohesion and flow behavior post-compaction.

- Compaction/Compressing:

- Investigates the caking potential and flow properties by varying compaction force and flow speed.

- Slicing/Shearing:

- Moves through the powder column with minimal disturbance, ideal for assessing the strength of a compacted cake.

Applications of the Powder Flow Tester:

The Powder Flow Tester is used across various industries for different purposes. Here’s a table summarizing its applications:

| Industry | Application |

|---|---|

| Pharmaceuticals | Optimizing drug formulations, ensuring uniformity and consistency |

| Food Production | Analyzing ingredient flow, ensuring product quality and consistency |

| Material Sciences | Researching powder properties, developing new materials |

| Chemical Industry | Assessing flow behavior of chemical powders, improving production processes |

| Cosmetics | Ensuring consistency and quality of powdered products |

| Additive Manufacturing | Testing powder flowability for 3D printing applications |

Advantages of the Powder Flow Tester

The Powder Flow Tester offers several benefits:

- Precision and Accuracy:

- Provides highly accurate and reproducible measurements of powder flow properties.

- Versatility:

- Can perform various tests, including slicing, shearing, compressing, compacting, and aerating cycles.

- Real-Time Data Analysis:

- Immediate analysis of test data allows for quick adjustments and decision-making.

- User-Friendly:

- Pre-programmed tests and straightforward installation and calibration enable easy use.

- Minimized Operator Error:

- Conditioning the powder column removes variations due to different operators.

Disadvantages of the Powder Flow Tester

Despite its many advantages, the Powder Flow Tester has a few drawbacks:

- Cost:

- The initial investment in the equipment can be high.

- Training:

- Operators may require training to fully utilize the instrument’s capabilities.

- Maintenance:

- Regular maintenance is necessary to ensure consistent performance.

Frequently Asked Questions (FAQs)

What is a Powder Flow Tester used for?

Answer: The Powder Flow Tester is used to measure and analyze the flow properties of powdered materials, ensuring consistency and quality in various industries.

How does the Powder Flow Tester work?

Answer: It measures axial force, time, and distance as the powder undergoes controlled flow operations, providing real-time data analysis to assess powder behavior.

What industries benefit from using a Powder Flow Tester?

Answer: Industries such as pharmaceuticals, food production, material sciences, chemicals, cosmetics, and additive manufacturing benefit from using the Powder Flow Tester.

What are the key features of the Powder Flow Tester?

Answer: Key features include conditioning the powder column, real-time data analysis, versatile testing capabilities, controlled flow displacement, and a patented helical blade.

What are the advantages of using a Powder Flow Tester?

Answer: Advantages include precision and accuracy, versatility, real-time data analysis, user-friendliness, and minimized operator error.

Are there any disadvantages to using a Powder Flow Tester?

Answer: Disadvantages include high initial cost, the need for operator training, and regular maintenance requirements.

How does the helical blade improve the testing process?

Answer: The precision-engineered helical blade ensures minimal disturbance as it cuts through the powder column, providing highly reproducible results without the need for complex torque measuring systems.

Can the Powder Flow Tester be customized for specific testing needs?

Answer: Yes, users can fully program the instrument to perform various cycles in any combination, catering to specific testing requirements.

What is the role of Exponent software in the Powder Flow Tester?

Answer: Exponent software displays and analyzes the test data in real-time, allowing for immediate assessment and comparison of results.

How does the Powder Flow Tester handle variations in sample loading?

Answer: The initial conditioning of the powder column removes variations caused by different operators, ensuring consistent and reliable results.