The objective of this Standard Operating Procedure for Calibration of Instruments by External Agencies is to outline the process and guidelines for calibrating instruments by external agencies to ensure accurate and reliable measurements in accordance with industry standards and regulatory requirements.

SOP for Calibration of Instruments by External Agencies

- OBJECTIVE:

- To lay down the procedure for the Calibration of Instruments by External Agencies.

- SCOPE:

- This SOP is applicable for the calibration of Instruments by External Agencies installed all the areas in plant premises.

- RESPONSIBILITY:

- User department shall be responsible for providing a list of equipments/ instruments for calibration of Instruments by External Agencies.

- Engineering – Head or designee shall be responsible for reviewing the SOP and for ensuring proper execution of calibration of instruments.

- ACCOUNTABILITY:

- Engineering – Head shall be accountable for proper implementation of the SOP.

- DEFINITIONS:

- Nil

- PROCEDURE:

- Engineering department person will shall co-ordinate with the calibration of Instruments by External Agencies.

- The instruments are calibrated by any other NABL/ETDC/ any Government authorized agencies as per the scheduled calendar.

- Calibration of instruments outside the plant.

- The instrument shall be sending to external agencies for calibration through purchase department by describing the user requirement as per Indent format.

- On the receipt of calibrated instruments and their calibration certificates from external agencies, Engineering Department Personnel shall verify calibration certificates to ensure calibrates and correctness as below mentioned.

Calibration of Instruments by External Agencies.

- Name of instrument.

- Identification No. /Sr. No of the instruments.

- Calibration Periodicity/Frequency.

- Name and address of the certified agency.

- Calibration certificate number.

- Instrument Make.

- Accuracy.

- Date of calibration.

- Due date of calibration.

- Calibrated and approved signature with stamp.

- Testing results.

- Environmental conditions.

- Master instrument number.

- Master instrument validity.

- Master instrument traceability no.

- Xerox copy of master instrument certificate.

- Verify the master gauge /instrument certificate of the above instrument for the following

- Master gauge Number.

- Master gauge traceability number.

- Accuracy.

- Environmental conditions.

- Date of calibration.

- Due date of calibration.

- Approval.

- Verify the tag of calibrated instrument for the following

- Instrument ID.

- Name of Instrument.

- Location of instrument.

- Date of calibration.

- Due date of calibration.

- Calibration done by.

- Checked by

- If any abnormalities are observed during verification, engineering department shall back the calibration certificate for rectification.

- Engineering department person shall compare the acceptance criteria given in List of Measuring Instruments as per SOP Format No.SOP/EN/XXXYYY.

- If any abnormalities observed inform to QA Department through “Out of Calibration Intimation Note” as per SOP Format No. SOP/EN/XXXYYY and instrument shall not be used for operation.

- Engineering Department shall take the necessary action as per QA recommendations.

- If there is no abnormalities on instrument it will be tagged with “Calibrated” Tag or the calibrated agency tag whichever is clearly visible and it shall be used for routine operations.

- Calibrations status of the instrument shall be recorded in calendar / instrument as per Format No.SOP/EN/XXXYYY.

- Calibration of instruments by external agencies inside the plant:

- Engineering Department shall inform to Purchase Department sending the list of gauges / instruments to be calibrated, in advance to due date, along with user requirements as per indent format.

- Purchase department shall intimate or raise the work order to concerned external agencies to perform the calibration.

- Sensor/ Transmitter (pressure, differential pressure, temperature, RH, ph, conductivity, ORP, flow and level) calibration to be done by open loop calibration method if space is not available for closed loop method.

- Note: in Calibration of Instruments by External Agencies.

- Sensor calibration to be done by removing the sensor from the equipment for all required points followed by loop calibration of display units for working range.

- On the receipt of intimation /work order from Purchase Department, external agency personnel shall carry out the calibration of gauges / instrument inside the plant & carried out the calibration as per vendor approved SOP from QA department.

- The external party shall perform the calibration in the presence of engineering department person and user department person.

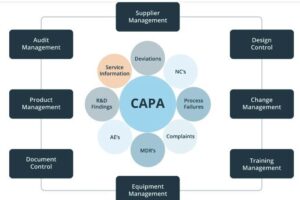

- During external party calibration if any deviation will occur shall be notified through plant QMS system.

- At the time calibration online print from equipment shall be taken as proof of raw data.

- Engineering department ensure that the operating range of the instrument should be cover at the time of calibration.

- After completion of calibration, concerned external agency shall send the calibration certificate to Engineering Department.

- On the receipt of calibration certificate, Engineering Department Personnel shall verify the certificate to ensure completeness and correctness as per the point and hand over the final Calibration certificates to QA department for final stamping & reviewed.

- If any abnormalities are observed during verification, Engineering Department shall send back the calibration certificate for rectification.

- Engineering Department person shall compare the Accuracy /Acceptance criteria are given on calibration certificate with the acceptance criteria as per SOP/EN/XXXYYY Format No.SOP/EN/XXXYYY List of Measuring Instruments.

- If any abnormalities observed inform to QA Department through “Out of Calibration and Intimation Note”SOP Format No. SOP/EN/XXXYYY and the instrument shall not be used for operations

- Engineering Department shall take the necessary action as per QA recommendations.

- If there are no abnormalities on instrument it will be tagged with Calibrated Tag or the calibration agencies tag as per SOP No. SOP/EN/XXXYYY whichever is clearly visible and it shall be used for routine operations.

- In case of master instrument follow the procedure of Engineering Department Person shall verify the certificates to ensure completeness and correctness.

- All the calibration certificates issued by external agencies are filed in Engineering Department after approval of QA.

- ABBREVIATIONS: in Calibration of Instruments by External Agencies.

- CRF No. : Change Request Form number

- QA : Quality Assurance

- NABL : National accreditation board for testing & calibration Laboratory

- ETDC : Electronics test and development centre.

- SOP : Standard operating Procedure

- REFERENCES

- Nil.

- DISTRIBUTION LIST

- SOP shall be distributed to the following departments Quality Assurance, Engineering as per user request

- ANNEXURES

- Nil