TPM is a pharmaceutical plant approach that seeks to improve that enables continuous and rapid improvement of the manufacturing process through employee participation, employee empowerment, a healthy work environment, and closed-loop results measurement. TPM kept the pharmaceutical equipment in good working order. In other words, TPM is the medical science of machines.TPM puts maintenance in the spotlight as a crucial and essential component of the business. The production day includes a breakdown for maintenance, and in some circumstances, maintenance downtime is a necessary component of the production process.

Total Productive Maintenance Goal in Pharmaceuticals:

The TPM aims to eliminate all losses, covering startup and yield losses as well as failures, equipment setup and readjustment losses, idleness and minor stoppages, reduced speed, faults and repairs, spills, and process upset situations. TPM also aims for zero equipment breakdowns and zero product defects, which lead to improved utilization of production assets and plant capacity.

Types of maintenance :

- Breakdown maintenance

- Preventive maintenance

- Periodically maintaining means (Time-based maintenance i.e. TBM)

- Predictive maintenance

- Corrective maintenance

- Maintenance prevention

- Autonomous maintenance

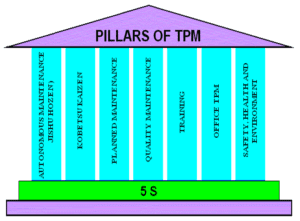

Pillars of TPM:

Pillar 1 – 5S: 5S is the foundation of the TPM

| Japanese Term | English Translation | Equivalent ‘S’ term |

| Seiri | Organization | Sort |

| Seiton | Tidiness | Systematize |

| Seiso | Cleaning | Sweep |

| Seiketsu | Standardization | Standardize |

| Shitsuke | Discipline | Self-Discipline |

Pillar 2 – JISHU HOZEN:

- Policy:- Make a plan & run uninterrupted operation of equipment.

Flexible machine operators to run and maintains the other equipment.

A stepwise implementation of Jishu Hozen activities.

- Targets: Prevent the occurrence of breakdown.

50% less oil should be used.

Cut the processing time in half.

Steps involved in the JISHU HOZEN: Participation of employees, Initial cleanup of machines, and taking countermeasures by the machine operator. Also general inspection, Autonomous inspection, Standardization, and Autonomous management.

Pillar 3 – KAIZEN

The word KAIZEN stands for the word “Kai” which means ‘change’ and “Zen” which means ‘good’.

The principle behind the kaizen is, a very large number of small improvements are more effective in an organizational environment than a few improvements of large value.

Policy and Targets :

– To reach cost-cutting goals across all resources.

– To increase the overall efficiency of plant equipment.

– Focus on easy handling of operations.

– Achieve and sustain zero loss with respect to minor stops, measurement,s and adjustments.

– It also aims to achieve a 30% manufacturing cost reduction.

Pillar 4 – PLANNED MAINTENANCE

It is aimed to have trouble-free machines and equipment producing defect-free products.

Planned maintenance is categorized into four parts as follows:

- Preventive Maintenance

- Breakdown Maintenance

- Corrective Maintenance

- Maintenance Prevention

The target of Planned Maintenance:

- Zero equipment failure and breakdown.

- Improve reliability and maintainability.

- Reduce maintenance costs.

- Make sure spares are always available.

Six steps in planned maintenance

- Equipment evaluation and recording present status with status Lable.

- Restore deterioration and improve weakness

- Building up the information management system, and equipment history card.

- Prepare a time-based information system.

- Always get ready for preventive maintenance.

- Evaluation of planned maintenance by SME.

Pillar 5 – QUALITY MAINTENANCE

Quality maintenance aimed towards customer delight through the highest quality through defect-free drug manufacturing. Based on the fundamental idea of purposeful way for equipment to maintain the perfect quality of products, QM’s activity is to establish equipment conditions that forbid quality flaws.

Policy:

- Fault-free conditions and machine control.

- QM activities that support quality management.

- Focus on the prevention of defects at the source.

- Focus on Poka-Yoka (foolproof system)

- In-line detection and segregation of defects

Target:

- Achieve and sustain customer complaints at zero

- Reduce in-process defects.

- Reduce the cost of quality.

Pillar 6 – TRAINING

The main tenet of TPM is a consistent training program. The goal is to have multi-skilled personnel who are motivated, excited to come to work, and capable of carrying out all necessary tasks efficiently and on their own.

Employees are trained to achieve four phases of skills:

Phase 1: Do not know.

Phase 2: Understand the concept but be unable to apply it.

Phase 3: Can perform but not instruct.

Phase 4: Can teach while working.

Policy: Create a training Planner with training records

- Focus on improvement of knowledge and skills

- Create a training environment for self-learning

- Training to reduce worker tiredness and improve the quality of their work

Target:

- Every employee will be trained and skilled as per job needs.

- Obtain and maintain zero losses as a result of ignorance, incompetence, or poor methods.

Steps in education and training activities

- Establishing priorities and strategies and assessing the current state of training and education.

- Create a training program to improve your skills.

- Creating a training schedule.

- Activity assessment and future product research.

Pillar 7 – OFFICE TPM

Generate the TPM Office and addresses 12 major losses

- Processing loss.

- Cost overruns in the accounts, marketing, and sales departments.

- Lack of communication.

- Lazy loss.

- Setup failure.

- Accuracy decline.

- Breakdowns of office equipment, telephones, work orders, and mail.

- The communication channel has broken down.

- Time spent on information retrieval.

- Incorrect online stock status is unavailable.

- Logistics-related complaints from customers

- Expenses for emergency goods and dispatching.

Benefits:

- Participation of all individuals in support activities with an emphasis on improving plant performance.

- Better utilized work area.

- Reduce repetitive work.

- Reduce administrative costs.

- Decrease in the volume of files.

- Equipment reduction in the office.

- Cut down on consumer complaints.

- Reduce the workforce.

Pillar 8 – SAFETY, HEALTH, and ENVIRONMENT

Target:

- Zero accident

- Zero Health damage

- Zero fires

- It helps to create a safe workplace and a surrounding area that is not damaged by our processes or procedures.

- t regularly participates actively in each of the other pillars.

- To create awareness among employees various competitions like safety slogans, quizzes, drama, posters, etc can be organized at regular intervals.

CONCLUSION and Merits:

Total Productive Maintenance (TPM) always Aims to follow aspects:

- Zero failure.

- MTBF (mean time between failures should be minimized) (mean time between failures should be minimized)

- Efficiency in breakdown maintenance should reduce MTRR (mean time to repair).

- Planning and carrying out preventive maintenance is important.

- Planning and implementing predictive maintenance is necessary.

- The warranty of maintenance concept should be implemented as per SOP.

For more technical details, best equipment maintenance practices, and their implementation in your plant, Please contact: admin@flairpharma.com

For knowledge about the Blood Groups knowledge base please click here.