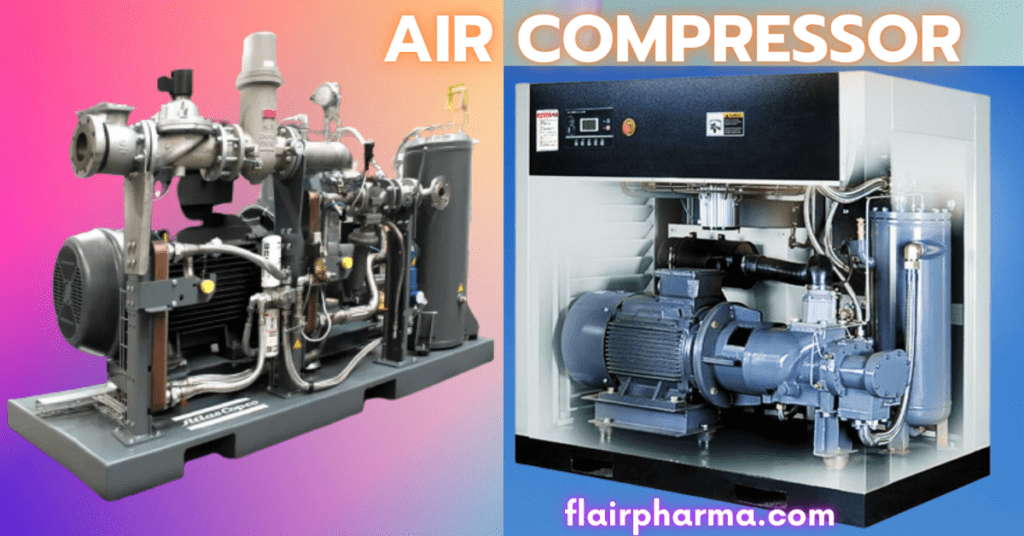

Air compressor plays an important role in biotech and pharmaceutical plants, serving as a versatile utility that supports critical processes and operations. Its importance can be attributed to several key factors that contribute to the overall efficiency, quality, and safety of manufacturing in these industries.

Let’s explore the significance of compressed air in biotech and pharmaceutical plants:

- Equipment and Instrument Operation.

- Air Filtration and Sterilization.

- Cleaning and Drying Processes.

- Fluid Transfer and Material Handling.

- Packaging and Labeling.

- Quality Control and Testing.

Working principle of the air compressor:

The working principle of an oil-free air compressor revolves around the concept of air compression without the presence of lubricating oil. Unlike oil-lubricated compressors, which use oil for cooling, sealing, and lubrication, oil-free compressors employ alternative mechanisms to ensure reliable and contaminant-free compressed air production. Here’s a breakdown of the working principle of an oil-free air compressor:

- Air Intake:

- The process begins with the intake of atmospheric air through an inlet. The air is drawn into the compressor system, typically through an air filter, which removes particulates and contaminants to ensure the cleanliness of the compressed air.

- Compression Chamber:

- Inside the compressor, the air enters a compression chamber, which consists of one or more pistons or rotors. The primary purpose of these components is to compress the air, reducing its volume while increasing its pressure. The compression occurs without the need for oil as a lubricant or cooling medium.

- Cooling and Heat Management:

- During the compression process, the air temperature rises due to the adiabatic heating effect. To prevent excessive heat buildup and ensure efficient operation, oil-free compressors employ various cooling mechanisms. This can include intercoolers and aftercoolers, which remove heat from the compressed air between stages, as well as external cooling systems, such as air or water cooling.

- Air Treatment:

- After compression and cooling, the compressed air undergoes further treatment to remove any remaining moisture and contaminants. This typically involves passing the air through moisture separators, coalescing filters, and other filtration systems. These components ensure the production of clean, dry, and oil-free compressed air suitable for various applications.

- Storage and Distribution:

- The oil-free compressed air is then stored in a receiver tank, allowing for immediate use or future demand. From the receiver tank, the compressed air can be distributed to different points of use within the system through piping networks. Valves and control mechanisms regulate the flow and pressure of the compressed air, ensuring optimal operation and efficiency.

- Continuous Operation:

- Oil-free compressors are designed to provide a continuous supply of compressed air. They may utilize various control systems, such as pressure switches or electronic controllers, to monitor and maintain the desired air pressure within predefined limits. This ensures stable and consistent operation while adapting to changing demands.

By eliminating the need for oil lubrication, oil-free air compressors offer several advantages, such as reduced maintenance requirements, elimination of oil contamination risks, and the production of clean and oil-free compressed air suitable for sensitive applications, such as in biotech, pharmaceutical, and food industries.

Major components of the Air Compressor

| Component | Description |

|---|---|

| Air Intake Filter | Filters incoming air, removing particulates and contaminants |

| Air Inlet Valve | Controls the flow of air into the compressor |

| Air Compression Chamber | Where the compression of air takes place |

| Intercoolers | Cools the compressed air between stages to improve efficiency |

| Aftercoolers | Further cools the compressed air before it leaves the compressor |

| Moisture Separator | Removes moisture from the compressed air |

| Air Receiver Tank | Stores the compressed air for immediate use or future demand |

| Pressure Relief Valve | Releases excess pressure to prevent damage or accidents |

| Control Panel | Houses the controls and indicators for operating the compressor |

| Drive Motor | Powers the compressor and drives the compression mechanism |

| Cooling System | Provides cooling for the compressor and its components |

| Discharge Valve | Controls the flow of compressed air out of the compressor |

| Silencer | Reduces noise produced by the compressor during operation |

| Electronic Controller | Monitors and regulates compressor performance and operation |

Technical Specifications of an Air Compressor

| Specification/Feature | Description |

|---|---|

| Power Rating | Indicates the power consumption of the compressor (in HP or kW) |

| Maximum Pressure | The highest pressure that the compressor can generate and deliver |

| Free Air Delivery | Actual volume of compressed air delivered (in CFM or L/min) |

| Tank Capacity | Size or volume of the storage tank accompanying the compressor |

| Duty Cycle | Percentage of operating time in relation to a complete cycle |

| Noise Level | Sound intensity produced by the compressor during operation (in dB) |

| Motor Type | Type of motor used to power the compressor (e.g., induction, VSD) |

| Cooling System | Components and methods used to manage the compressor’s temperature |

| Control System | Mechanisms for operating and regulating the compressor |

| Filtration System | System for removing particles, contaminants, and moisture from air |

Quality of Compressed Air in Pharmaceutical Plants as per ISO Standards

In pharmaceutical plants, the quality of compressed air is of utmost importance to ensure the integrity and safety of the manufacturing processes and the final pharmaceutical products. The International Organization for Standardization (ISO) has established standards to define acceptable levels of air quality in various industries, including pharmaceutical manufacturing. Let’s explore the quality requirements of compressed air in pharmaceutical plants based on ISO standards.

ISO 8573-1 Classification:

ISO 8573-1 is the standard that outlines the classification of compressed air purity. It defines different classes for various contaminants, including particles, moisture, and oil content. The classification consists of three numbers representing each contaminant class, with lower numbers indicating stricter requirements. Here is a summary of the key contaminants and their permissible limits for compressed air used in pharmaceutical plants:

- Particle Contamination (ISO 8573-1:2010):

- Class 0: No particles allowed (measured as 0.1 to 0.5 microns).

- Class 1: Maximum allowable particle count per cubic meter: ≥ 0.1 µm: 20,000; ≥ 0.5 µm: 400; ≥ 1 µm: 10; ≥ 5 µm: 0.

- Moisture Content (ISO 8573-1:2010):

- Class 0: No moisture allowed.

- Class 1: Maximum pressure dew point: -70°C (-94°F).

- Oil Contamination (ISO 8573-1:2010):

- Class 0: No oil allowed.

- Class 1: Maximum oil concentration: 0.01 mg/m³.

Additional Considerations:

Apart from the ISO 8573-1 classification, pharmaceutical plants also need to adhere to specific requirements based on their processes and product specifications. These additional considerations may include:

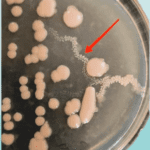

- Microbial Contamination: Pharmaceutical plants may implement microbial monitoring and control measures to prevent microbial contamination in compressed air systems. This involves regular testing, air filtration, and sterilization techniques.

- Validation and Monitoring: Pharmaceutical plants often perform validation and routine monitoring of compressed air systems to ensure compliance with quality standards. This includes periodic testing of air quality parameters and maintenance of appropriate documentation.

- Compliance with Good Manufacturing Practices (GMP): Pharmaceutical plants must comply with Good Manufacturing Practices, which may include guidelines related to compressed air quality. GMP regulations aim to ensure the consistent quality and safety of pharmaceutical products.

Frequently Asked Question

What is an air compressor?

Answer: An air compressor is a mechanical device that converts power, typically from an electric motor or an engine, into potential energy stored in compressed air. It pressurizes and stores air to be used for various applications.

What are the types of air compressors?

Answer: There are several types of air compressors, including reciprocating (piston) compressors, rotary screw compressors, centrifugal compressors, and scroll compressors. Each type has its own advantages and is suitable for specific applications.

What is the purpose of an air compressor?

Answer: The primary purpose of an air compressor is to generate compressed air for powering pneumatic tools and machinery, supplying clean air for industrial processes, and facilitating various applications such as air conditioning, refrigeration, and spray painting.

How does an air compressor work?

Answer: In general, an air compressor works by drawing in air through an intake, compressing it using pistons, rotors, or impellers, and then storing the pressurized air in a tank. The compressed air can be released and used for various purposes as needed.

What factors should I consider when choosing an air compressor?

Answer: When selecting an air compressor, you should consider factors such as the required air pressure and volume (CFM), the type of application, power source availability, tank size, noise level, and maintenance requirements. It’s also important to ensure the compressor matches your specific needs and budget.

How do I maintain an air compressor?

Answer: Regular maintenance is crucial for the proper functioning and longevity of an air compressor. This typically involves checking and replacing filters, inspecting for leaks, monitoring oil levels (for oil-lubricated compressors), cleaning or replacing belts, and conducting routine inspections according to the manufacturer’s guidelines.

Are there any safety precautions I should take when using an air compressor?

Answer: Yes, safety precautions are important when using an air compressor. These include wearing appropriate personal protective equipment, following proper operating procedures, ensuring proper electrical connections, relieving pressure before performing maintenance, and being mindful of potential hazards associated with compressed air.

Can I use an air compressor for medical or breathing air applications?

Answer: Standard air compressors are not suitable for producing breathing air. However, specialized medical-grade air compressors equipped with air treatment systems can be used to produce clean and dry air for medical and breathing air applications, adhering to specific regulations and standards.

1 thought on “Air Compressor Working Principle in Pharma industry 2023”