Eliminating microbial contaminations from a classified area, such as a cleanroom or controlled environment, is crucial in industries like pharmaceuticals, biotechnology, electronics manufacturing, and healthcare. Here are some general guidelines and methods to control and eliminate microbial contaminations:

- Cleanroom Design:

- Ensure proper cleanroom design and construction to minimize the entry of contaminants. This includes using appropriate materials, maintaining positive air pressure, and having efficient ventilation systems.

- Personnel Training:

- Train personnel on proper cleanroom procedures, hygiene, and gowning techniques. Strict protocols for entering and exiting the cleanroom should be followed.

- Gowning Procedures:

- Enforce stringent gowning procedures to prevent microbial shedding from personnel. This may include the use of sterile gowns, gloves, masks, and hair covers.

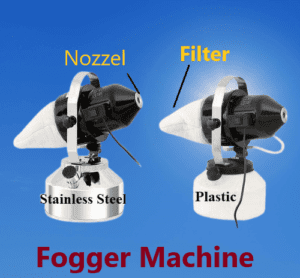

- Air Filtration:

- Use high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters in the ventilation system to remove airborne particles, including microbes.

- Surface Disinfection:

- Regularly disinfect all surfaces within the classified area using suitable disinfectants. The choice of disinfectant should be based on the type of microbes present and the materials in the cleanroom.

- Routine Cleaning:

- Establish a routine cleaning schedule for the entire cleanroom, including floors, walls, ceilings, and equipment. Use cleaning agents that are effective against a broad spectrum of microbes.

- Validation and Monitoring:

- Regularly validate and monitor the cleanroom environment to ensure compliance with specified cleanliness levels. This may involve particle counts, microbial monitoring, and air quality testing.

- Material Handling:

- Implement proper procedures for material and equipment transfer into and out of the cleanroom to prevent contamination. This may include pass-through chambers or airlocks.

- HVAC System Maintenance:

- Regularly maintain and monitor the heating, ventilation, and air conditioning (HVAC) system to ensure its efficiency. Proper maintenance prevents the growth and spread of microbes within the ventilation system.

- Quality Control and Documentation:

- Implement a robust quality control system and maintain detailed documentation of cleaning and disinfection activities. This documentation is essential for regulatory compliance.

- Isolation of Processes:

- If possible, isolate processes that are more prone to microbial contamination from other cleanroom activities. This helps prevent cross-contamination.

- Regular Audits:

- Conduct regular audits and inspections to identify potential sources of contamination and ensure compliance with cleanliness standards.

Remember that the specific procedures and protocols may vary depending on the industry and regulatory requirements. Always follow industry-specific guidelines and consult with experts in cleanroom management to tailor your approach to the specific needs of your classified area.

FAQ:

How can microbial contamination be removed?

- Cleaning: Regular and thorough cleaning of surfaces using appropriate disinfectants to remove microbial contaminants.

- Sterilization: Employing methods such as autoclaving, irradiation, or chemical sterilants to kill or eliminate microorganisms.

- Filtration: Using filters, such as HEPA filters, to remove microbes from air or liquids.

- Disinfection: Applying chemical agents to surfaces or equipment to kill or inhibit the growth of microorganisms.

- Heat Treatment: Subjecting materials or equipment to high temperatures to eliminate microbial contamination.

How can we reduce microbial contaminations?

- Good Hygiene Practices: Implementing proper personal hygiene measures for individuals entering clean areas.

- Airflow Control: Maintaining controlled airflow to prevent the entry of contaminants into clean areas.

- Gowning Procedures: Enforcing strict gowning protocols to minimize the shedding of microbes from personnel.

- Isolation: Isolating processes or equipment that are more prone to contamination.

- Regular Cleaning: Establishing routine cleaning schedules for both surfaces and equipment.

How can microbiological contamination be prevented?

- Personnel Training: Educating personnel on proper procedures to minimize the risk of contamination.

- Environmental Monitoring: Regularly monitoring the environment for microbial presence.

- Material Control: Implementing measures to control the entry of materials and equipment into clean areas.

- Effective Ventilation: Ensuring proper ventilation systems to maintain the desired air quality.

What are the methods used in the control of microbial contaminants in the environment?

- Cleanroom Design: Constructing controlled environments with features that minimize contamination.

- Air Filtration: Using air filtration systems to remove airborne particles, including microorganisms.

- Sterilization and Disinfection: Employing methods to kill or inhibit microbial growth on surfaces and equipment.

- Routine Monitoring: Regularly testing and monitoring the environment for microbial presence.

What are the 4 methods of controlling microbial growth?

- Physical Methods:

- Heat treatment (e.g., autoclaving)

- Radiation (e.g., UV or ionizing radiation)

- Chemical Methods:

- Disinfection with chemical agents

- Sterilization using chemical sterilants

- Biological Methods:

- Use of antimicrobial agents produced by microorganisms (e.g., antibiotics)

- Mechanical Methods:

- Filtration of air or liquids to remove microorganisms

How is contamination controlled?

Contamination is controlled through a combination of:

- Preventive Measures: Implementing protocols to prevent the entry and spread of contaminants.

- Monitoring and Testing: Regularly assessing the environment for microbial presence.

- Cleaning and Disinfection: Thorough and routine cleaning to eliminate or reduce microbial contamination.

What are four ways to prevent contamination?

- Strict Hygiene Practices: Implementing rigorous personal hygiene measures for individuals entering controlled areas.

- Effective Gowning Procedures: Ensuring proper gowning to prevent the shedding of contaminants from personnel.

- Controlled Environment Design: Constructing facilities with features that minimize the risk of contamination.

- Routine Cleaning and Disinfection: Regularly cleaning and disinfecting surfaces and equipment.

What are the 3 most common types of microbial contamination?

- Bacterial Contamination: Presence of bacteria in a given environment.

- Viral Contamination: Presence of viruses, which are smaller than bacteria, in a given environment.

- Fungal Contamination: Presence of fungi, including molds and yeasts, in a given environment.

What is contamination control in microbiology?

Contamination control in microbiology involves the implementation of measures to prevent, monitor, and eliminate microbial contaminants in laboratories, cleanrooms, and other controlled environments. This includes practices such as proper hygiene, routine cleaning, sterilization, and environmental monitoring to ensure the integrity of experiments and production processes.

What are the methods of contamination removal?

- Cleaning: Using cleaning agents to physically remove contaminants from surfaces.

- Sterilization: Employing methods to completely kill or eliminate microorganisms.

- Filtration: Using filters to remove microbes from air or liquids.

- Disinfection: Applying chemical agents to surfaces or equipment to kill or inhibit the growth of microorganisms.

How do you remove contamination?

Contamination can be removed through:

- Cleaning: Physically wiping or scrubbing surfaces to remove contaminants.

- Sterilization: Using methods like autoclaving or irradiation to kill microorganisms.

- Filtration: Employing filters to remove microbes from air or liquids.

- Disinfection: Applying chemical agents to surfaces to eliminate or inhibit microbial growth.

What is microbial elimination?

Microbial elimination refers to the complete removal or destruction of microorganisms. This can be achieved through various methods such as sterilization, disinfection, or filtration, depending on the context and the specific requirements for microbial control. The goal is to eliminate the presence of viable microorganisms to ensure a sterile or controlled environment.

The major sources of microbial contamination in a cleanroom?