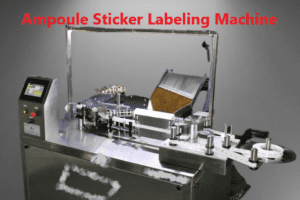

A machine to label full and sealed ampoules is known as a high-speed ampoule sticker labeling machine or high-speed ampoule labeler or ampoule Labeling Machine. Modern ampoule and vial filling requires high-end equipment, which is exactly what our automatic high-speed ampoule labeling machine provides. This device is used to label ampoules and vials of various forms quickly. To apply even clear or no-look labels, this rotary labeling machine has a unique mechanism made up of mechanical and electronic components. Moreover, it has a coordinated speed control system.

Our high-speed vial labeling machine is the best option if you’re looking for a device that enables you to meet high production goals without any mistakes or downtime. Up to 600 goods can be labeled by it in a single minute. The ampoules or vials are fed using a special feeding apparatus and labeled ampoules or vials can be retrieved from the trays. Because the operator doesn’t have to stop the machine from performing either of these duties, ampoule feeding and labeling don’t necessitate pausing the process. Another important factor is that vials and ampoules are not damaged. Ampoule labeling will be done after the Inspection of the ampules by the Ampoule inspection machine.

Please contact us with any questions regarding our stainless steel, high-speed ampoule labeling machine. We will be more than delighted to assist you if you need a free, no-obligation quote for an automatic, high-speed ampoule-vial combo sticker labeling machine.

Working principle of automatic ampoule labeling machine

The Sticker and labeling machine needs a specific set of rules to function properly throughout its complete system. Then, the object or container that needs to be labeled is placed on the sticker labelers, which operate at a specific speed on the machine’s conveyor. The technological fixture of the machine splits the things at a predetermined space, allowing the system to push the inserted item in the intended direction of the conveyor. This is another operating concept of the sticker labeler. Hence, some of the key components of the sticker labeling machine are the drive wheel, labeling wheel, and reel.

The infeed hopper unit of equipment is where ampoules are immediately loaded when it comes to operating ampoule labelers. From there, the ampoules should be fed to the feed worm. The feed worm’s job is to revolve around the turning star wheel. The ampoules are identified individually during subsequent processing using this star wheel. The pressing unit is another significant component of the ampoule labeling machine and is essential to the equipment’s operation.

Major Components of automatic ampoule labeling machine

Component | Material |

| Machine Main Base Frame | Stainless Steel 304 Pipe Structure |

| Machine Coverings | Complete in Stainless Steel 304 |

| Product Contact Parts | Stainless Steel 304 |

| Non-Contact Parts | Stainless Steel / Mild Steel / Aluminium / Teflon |

| Star-wheel | Stainless steel with Teflon/stainless steel roller |

| Feed worm | Teflon material |

| Tray for infeed | Stainless Steel with chain-type conveyor |

| Tray for outfeed | Stainless Steel |

| Bearings | SKF / Niche / Equivalent |

| Plating(Wherever Applicable) | Zinc / Hard Chrome / Blackening |

| Wrapping Belt | End Less Sponge Coated Wrapping Belt |

| Bottle Separation / Spacing Unit | Teflon material Feeds worm |

| Dispenser Rollers | Rubber Molded + Aluminium + Knurling Rollers |

| Dispenser Unit Up & Down | Screw Based UP & DOWN Assembly |

Best manufacturers of automatic ampoule labeling machine

- Maharishi.

- NKP.

- Adinath International.

- Shree Bhagwati labeling Technologies.

- Harsiddh Engineering Co.

Frequently Asked Questions:

What is an ampoule labeling machine?

Answer: An ampoule labeling machine is a specialized equipment used in the pharmaceutical industry to automatically apply labels onto ampoules, which are small sealed glass containers used for storing and dispensing medications.

How does an ampoule labeling machine work?

Answer: An ampoule labeling machine typically consists of a conveyor system that transports ampoules, a label application mechanism, and an optical system for precise label placement. The machine applies labels onto ampoules with high accuracy and speed.

What are the key features to consider when selecting an ampoule labeling machine?

Answer: Important features to consider include labeling speed, accuracy, label placement precision, compatibility with different ampoule sizes, ease of operation and maintenance, validation support, and compliance with regulatory requirements.

What types of labels can be applied by an ampoule labeling machine?

Answer: Ampoule labeling machines can apply various types of labels, including paper labels, transparent labels, holographic labels, and serialized labels with unique identification codes.

How does an ampoule labeling machine ensure label placement accuracy?

Answer: Label placement accuracy is achieved through the use of optical sensors and vision systems that precisely detect the position and orientation of ampoules, ensuring labels are applied in the correct location.

Can an ampoule labeling machine handle different sizes of ampoules?

Answer: Yes, many modern ampoule labeling machines are designed to accommodate a range of ampoule sizes. They often feature adjustable components or interchangeable parts to accommodate various ampoule dimensions.

What are the typical labeling speeds of ampoule labeling machines?

Answer: Labeling speeds can vary depending on the machine model and configuration. However, high-quality ampoule labeling machines can achieve speeds ranging from 200 to 600 ampoules per minute.

How are labels applied to ampoules by an ampoule labeling machine?

Answer: Labels are usually fed from a label roll and applied to ampoules using a combination of rollers, brushes, or air blowers. The labels are securely affixed to the ampoule surface to ensure proper adhesion.

Can an ampoule labeling machine handle fragile ampoules?

Answer: Yes, ampoule labeling machines are designed to handle fragile glass ampoules delicately. They often incorporate features such as gentle handling mechanisms, adjustable pressure settings, or cushioning systems to prevent damage during the labeling process.

Are ampoule labeling machines equipped with error detection systems?

Answer: Yes, advanced ampoule labeling machines are equipped with error detection systems. These systems can identify issues such as missing labels, incorrect label placement, or damaged labels, triggering an alarm or automatically stopping the machine to prevent defective products from reaching the market.

How are ampoule labeling machines validated for use in the pharmaceutical industry?

Answer: Validation of ampoule labeling machines typically involves a series of tests and documentation to ensure the machine meets the required standards. This may include performance qualification (PQ), installation qualification (IQ), operational qualification (OQ), and documentation of standard operating procedures (SOPs).

Are ampoule labeling machines compliant with regulatory requirements?

Answer: Yes, reputable ampoule labeling machine manufacturers design their equipment to comply with relevant regulatory requirements, such as Good Manufacturing Practices (GMP) and standards set by regulatory bodies like the FDA or EMA.

Can ampoule labeling machines integrate with other pharmaceutical production equipment?

Answer: Yes, ampoule labeling machines can be integrated with other pharmaceutical production equipment, such as ampoule filling machines or packaging lines. The integration enables seamless transfer of ampoules between different stages of the production process.

Click To read copies of Indian Pharmacopeias