An incubator in a microbiology lab is a specialized piece of equipment used to create and maintain controlled environmental conditions necessary for the growth and cultivation of microorganisms. It provides a controlled temperature, humidity, and often even CO2 levels to create an optimal environment for microbial growth and study. Microbiology incubators are essential for conducting various experiments, culturing bacteria, fungi, and other microorganisms, and conducting research in fields such as medical microbiology, environmental microbiology, and industrial microbiology. These incubators play a critical role in providing researchers with a reliable and controlled environment to study microbial growth, metabolism, and behavior, enabling them to better understand and manipulate microorganisms for various applications, including disease diagnostics, drug development, and biotechnological advancements.

Incubator Meaning

In microbiology and the pharmaceutical industry, an incubator refers to a specialized piece of equipment used to cultivate and grow microorganisms, such as bacteria, viruses, and fungi, under controlled conditions. These incubators provide a controlled environment of temperature, humidity, and often atmospheric conditions (such as CO2 concentration) to promote the optimal growth and reproduction of microorganisms.

In microbiology laboratories, incubators are used for various purposes, including the culture and isolation of microorganisms, testing the effectiveness of antimicrobial agents, studying microbial physiology and metabolism, and conducting experiments related to microbial genetics and molecular biology.

In the pharmaceutical industry, incubators are crucial for the production of vaccines, antibiotics, and other microbial-based products. They are used to grow and propagate microorganisms for vaccine production, conduct fermentation processes to produce antibiotics and other pharmaceutical compounds, and carry out quality control tests on microbial contaminants in pharmaceutical products.

Overall, incubators in microbiology and the pharmaceutical industry provide a controlled and optimal environment for the growth and manipulation of microorganisms, facilitating research, development, and production processes in these fields.

incubator diagram

Principle of incubator

The principle of an incubator is to create and maintain a controlled environment to support the growth and development of biological samples, such as microorganisms, cells, or tissues. The key principles involved in the functioning of an incubator are as follows:

- Temperature Control: Incubators are designed to provide precise and stable temperature control within a defined range. This is achieved through the use of heating elements and sensors that monitor the temperature inside the chamber. The heating elements are activated or deactivated as needed to maintain the desired temperature level.

- Environmental Stability: Incubators aim to create a stable and consistent environment for the samples by minimizing temperature fluctuations, humidity changes, and external influences. This stability ensures that the samples experience a controlled and predictable environment, necessary for their growth and development. (Stability Chambers)

- Sterility and Contamination Prevention: Incubators are equipped with features to maintain a sterile environment and prevent contamination. This includes air filtration systems, antimicrobial surfaces, and seals on doors or access points to minimize the entry of external contaminants.

- Gas Regulation (in some cases): Certain incubators, such as CO2 incubators, provide the ability to control the concentration of gases, particularly carbon dioxide (CO2). This is crucial for cell and tissue culture applications, where maintaining a specific CO2 level is necessary for optimal growth.

- Monitoring and Alarm Systems: Incubators often include monitoring systems that continuously measure and display the internal temperature, humidity, and other parameters. They may also have alarm systems to alert users if the conditions deviate from the desired setpoints, ensuring that any deviations are addressed promptly to prevent adverse effects on the samples.

By adhering to these principles, incubators create a controlled environment that promotes the growth, cultivation, and experimentation of biological samples in various fields such as microbiology, cell biology, tissue engineering, and pharmaceutical research. The precise control of temperature, stability, sterility, and gas regulation enables researchers and scientists to carry out their experiments and studies under controlled and reproducible conditions, ultimately contributing to the advancement of scientific knowledge and various applications in the biological and pharmaceutical sciences.

SOP of Incubators

Incubator(operation, Cleaning & Calibration)

Types of incubators in Pharma:

In the pharmaceutical industry, various types of incubators are used to support different processes and applications. Here are some common types of incubators found in pharmaceutical industries:

- Microbiological Incubators: These incubators are designed specifically for the cultivation and growth of microorganisms. They provide controlled conditions of temperature, humidity, and sometimes CO2 concentration to support the growth of bacteria, fungi, and other microorganisms used in research, testing, and production of pharmaceutical products.

- CO2 Incubators: CO2 incubators are used when the growth of cells or tissues in a controlled atmosphere with a specific level of carbon dioxide is required. They are commonly used in cell culture laboratories for growing mammalian cells, such as those used in the production of vaccines, monoclonal antibodies, and other biological drugs.

- Shaking Incubators: Shaking incubators combine incubation with mechanical agitation or shaking. They are used for applications such as bacterial or yeast cultures, where the constant movement of the cultures enhances oxygen and nutrient distribution, as well as the mixing of cells and media.

- Refrigerated Incubators: These incubators have the added capability of maintaining lower temperatures, typically ranging from 4°C to above room temperature. They are used for applications that require cooler conditions, such as the storage of sensitive reagents, enzymes, or samples that need to be kept at specific temperatures for stability.

- Hybridization Incubators: Hybridization incubators are used for DNA and RNA hybridization processes, which involve the binding of complementary nucleic acid sequences. These incubators provide precise and controlled temperature conditions for hybridization reactions, typically in the range of 50°C to 70°C.

- Anaerobic Incubators: Anaerobic incubators are designed to create an oxygen-free or low-oxygen environment for the growth of anaerobic microorganisms that cannot tolerate or require low levels of oxygen. They often include features such as gas chambers and gas regulators to control oxygen and other gas concentrations.

These are just a few examples of the types of incubators commonly used in the pharmaceutical industry. The specific choice of incubator depends on the requirements of the process, the organisms or cells being cultured, and the desired environmental conditions.

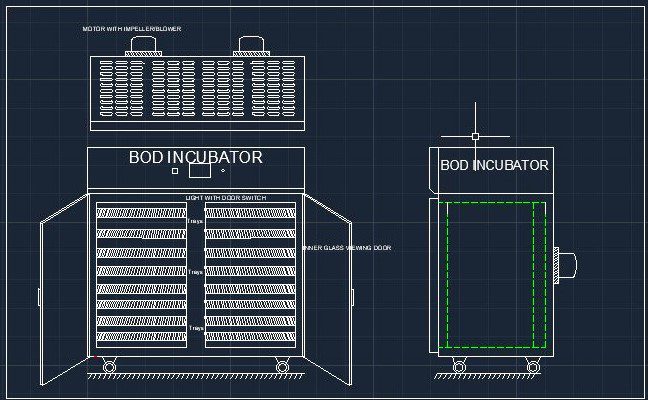

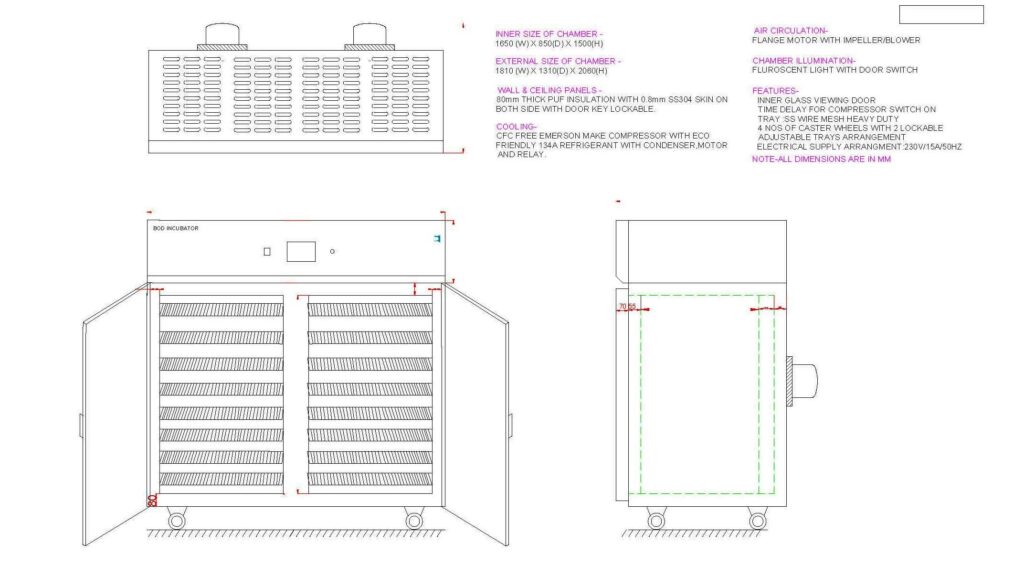

bod incubator

A BOD (Biochemical Oxygen Demand) incubator is a specialized type of incubator commonly used in the pharmaceutical industry for environmental monitoring and microbial testing. It is specifically designed to provide a controlled environment for the determination of biochemical oxygen demand, which is a measure of the amount of oxygen consumed by microorganisms during the decomposition of organic matter.

In the pharmaceutical industry, BOD incubators are used for various applications, including:

- Sterility Testing: BOD incubators provide a controlled environment for conducting sterility tests on pharmaceutical products. These tests involve incubating samples in a sterile medium to determine if any microorganisms are present.

- Microbial Limit Testing: BOD incubators are used to perform microbial limit testing, which involves determining the total viable microbial count in pharmaceutical products. The incubator creates optimal conditions for microbial growth to assess the presence and quantity of microorganisms.

- Environmental Monitoring: BOD incubators are utilized for environmental monitoring in pharmaceutical facilities. Samples from air, surfaces, or water are collected and incubated in BOD incubators to determine the presence and growth of microorganisms in the environment.

- Microbial Growth Promotion Testing: BOD incubators provide the necessary conditions for conducting microbial growth promotion testing on culture media used for microbial testing in pharmaceutical laboratories. This ensures that the media supports the growth of specified microorganisms effectively.

BOD incubators typically offer precise temperature control, often ranging from ambient temperature to around 45°C, and provide a stable and consistent environment for incubation. They may also include features such as programmable controls, alarms, and data logging capabilities for accurate and reliable testing.

By utilizing BOD incubators, the pharmaceutical industry can ensure compliance with regulatory requirements, evaluate the effectiveness of sterilization processes, and monitor the microbial quality of products and manufacturing environments.

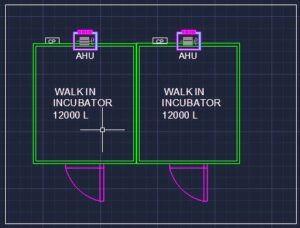

walk-in incubator

A walk-in incubator, also known as a walk-in environmental chamber, is a large-scale incubator that allows users to enter the chamber to perform work or monitor samples. It provides a controlled environment with specific temperature, humidity, and sometimes CO2 levels to support the growth, testing, or storage of various biological samples, research materials, or products on a larger scale. Here are some key features and considerations related to walk-in incubators:

- Size and Capacity: Walk-in incubators are significantly larger than standard-sized incubators and offer a greater internal capacity. They are designed to accommodate larger quantities of samples, equipment, or larger objects that require controlled environmental conditions.

- Accessibility: One of the primary advantages of a walk-in incubator is the ability for users to walk inside the chamber. This enables easier access for sample loading, manipulation, monitoring, and retrieval.

- Temperature Control: Walk-in incubators provide precise temperature control to maintain a consistent and uniform temperature throughout the chamber. They often use a combination of heating and cooling systems to achieve the desired temperature range.

- Humidity Control: Depending on the application, walk-in incubators may offer humidity control capabilities to maintain specific humidity levels. This is particularly important for certain research, storage, or production processes that require controlled moisture conditions.

- CO2 Control (if applicable): Some walk-in incubators, especially those used for cell culture or specific applications, may include CO2 control systems to regulate and maintain the desired CO2 levels within the chamber.

- Shelving and Racks: Walk-in incubators typically feature adjustable shelving or racks to maximize the utilization of space and facilitate organized placement of samples or equipment.

- Safety Features: Walk-in incubators incorporate safety features such as temperature alarms, power failure alarms, emergency stop buttons, and safety shut-off mechanisms to ensure the safety of the users and protect valuable samples or materials.

- Construction and Insulation: Walk-in incubators are constructed using durable materials and feature robust insulation to minimize heat transfer and ensure stability of the internal environment.

- Installation and Space Requirements: Due to their size, walk-in incubators require proper planning and installation in a dedicated space within the laboratory or facility. Considerations should be made for adequate ventilation, power supply, and clearances for maintenance and access.

- Monitoring and Controls: Walk-in incubators are equipped with control panels and displays to set and monitor temperature, humidity, CO2 levels (if applicable), and other parameters. Remote monitoring and data logging capabilities may also be available.

It’s important to note that specific features and specifications of walk-in incubators may vary depending on the manufacturer, model, and intended application. Therefore, it is recommended to consult the manufacturer’s documentation or contact the manufacturer directly for detailed information about a specific walk-in incubator.

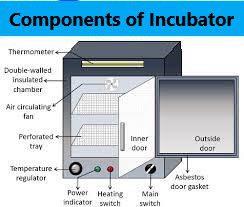

Major Components of the Incubators:

The major components of an incubator typically include:

- Chamber: The chamber is the main compartment of the incubator where samples or cultures are placed. It is usually made of a durable material such as stainless steel and is designed to maintain a controlled environment.

- Temperature Control System: The temperature control system regulates and maintains the desired temperature inside the incubator. It typically consists of heating elements, such as electric coils or heating pads, which raise the temperature, and a thermostat or temperature controller that monitors and adjusts the temperature as needed.

- Humidity Control System (optional): Some incubators, particularly those used for cell culture or specific applications, may have a humidity control system. It includes a water reservoir or humidifier to introduce moisture into the chamber and a humidistat or humidity controller to regulate the humidity levels.

- Ventilation System: An incubator requires a ventilation system to ensure proper airflow and prevent the accumulation of excess humidity, gases, or contaminants. It typically includes air vents, filters, and fans that circulate the air within the chamber.

- Door with Viewing Window: The incubator is equipped with a door that provides access to the chamber. The door may have a viewing window or a transparent panel that allows users to observe the samples without disrupting the internal environment.

- Controls and Displays: Incubators feature control panels located on the exterior of the unit. These controls allow users to set and adjust the temperature, humidity (if applicable), and other parameters. The incubator may also have digital displays or indicators to show the current values of these parameters.

- Safety Features: Incubators often include safety features such as alarms and safety shut-off mechanisms to protect the samples and equipment in case of temperature or humidity deviations, power failures, or other emergencies.

- Shelves or Racks: To accommodate samples or culture vessels, incubators typically have adjustable shelves or racks inside the chamber. These shelves allow for the organized placement of samples and optimize the use of space.

- Lighting System (optional): Some incubators have built-in lighting systems, especially those used for plant propagation or photoperiod-sensitive studies. These lights provide the necessary illumination for the samples, often with adjustable light intensity and photoperiod control.

Uses of incubator / Use of incubator

Incubators have a wide range of uses in various fields. Here are some common uses of incubators:

- Microbiology and Biotechnology: Incubators are extensively used in microbiology and biotechnology laboratories for culturing and growing microorganisms. They provide controlled conditions of temperature, humidity, and sometimes gas composition to support the growth of bacteria, fungi, yeast, and other microorganisms for research, testing, and production purposes.

- Cell Culture and Tissue Engineering: Incubators are essential for cell culture and tissue engineering applications. They provide the necessary environment for the growth and maintenance of cells and tissues, including controlled temperature, humidity, and gas concentrations (such as CO2 and O2 levels). This enables the study of cell behavior, drug testing, regenerative medicine research, and the production of cell-based products.

- Assisted Reproduction: Incubators play a critical role in assisted reproductive technologies, such as in vitro fertilization (IVF). They provide a controlled environment for culturing and developing embryos, ensuring optimal conditions for successful fertilization and early-stage embryo development.

- Poultry and Livestock: Incubators are used in the poultry and livestock industry for hatching eggs and rearing young animals. They provide controlled temperature and humidity levels to create favorable conditions for egg incubation, leading to successful hatching and healthy offspring.

- Plant Propagation: Incubators are utilized in horticulture and plant science for seed germination and plant propagation. They provide controlled temperature, humidity, and light conditions to promote the successful growth of seeds and the establishment of plant cuttings or tissue cultures.

- Food and Beverage Industry: Incubators are employed in the food and beverage industry for fermentation processes. They provide a controlled environment for the growth of specific microorganisms used in the production of yogurt, cheese, beer, wine, and other fermented products.

- Environmental Testing: Incubators are used for environmental monitoring and testing. They provide controlled conditions for culturing and identifying microorganisms present in environmental samples, helping to assess water quality, air pollution, and soil health.

- Research and Development: Incubators are fundamental tools in scientific research and development across various fields. They enable researchers to conduct controlled experiments, study the growth and behavior of organisms, investigate biochemical processes, and develop new products or technologies.

These are just a few examples of the many uses of incubators in different industries and scientific disciplines. The precise application of an incubator depends on the specific needs of the field or process in which it is being used.

Advantages and disadvantages of incubators

| Advantages of Incubators | Disadvantages of Incubators |

|---|---|

| 1. Controlled Environment: Optimal growth conditions | 1. Cost: Expensive to purchase, operate, and maintain |

| 2. Reliable and Consistent Results | 2. Space Requirement: Requires dedicated laboratory space |

| 3. Flexibility for customization | 3. Energy Consumption: Increased energy costs |

| 4. Protection against Contamination | 4. Limited Capacity |

| 5. Versatility in various fields and applications | 5. Monitoring and Maintenance |

| 6. Long-term Cultivation | 6. Potential Cross-contamination |

| 7. User-friendly Operation | 7. Limited Portability |

Troubleshooting in incubators

Frequently Asked Questions:

What is the purpose of an incubator?

Answer: An incubator is designed to create and maintain a controlled environment to support the growth and development of biological samples, such as microorganisms, cells, or tissues, for various research, testing, or production purposes.

How does an incubator regulate temperature?

Answer: Incubators regulate temperature using heating elements, such as electric coils or heating pads, controlled by a thermostat or temperature controller. The controller monitors the temperature inside the chamber and activates or deactivates the heating elements as needed to maintain the desired temperature.

What is the role of a CO2 incubator?

Answer: A CO2 incubator is specifically designed to provide a controlled environment with regulated temperature, humidity, and carbon dioxide (CO2) levels. It is commonly used for cell culture applications where maintaining a specific CO2 concentration is crucial for optimal cell growth and viability.

How does an incubator control humidity?

Answer: Some incubators have a humidity control system that includes a water reservoir or humidifier to introduce moisture into the chamber. A humidistat or humidity controller is used to monitor and adjust the humidity levels by controlling the amount of moisture released into the chamber.

What safety features should an incubator have?

Answer: An incubator should have safety features such as temperature alarms, power failure alarms, and safety shut-off mechanisms to protect the samples and equipment in case of temperature deviations, power disruptions, or other emergencies.

What is the importance of proper airflow in an incubator?

Answer: Proper airflow is important in an incubator to ensure uniform distribution of temperature, humidity, and gases within the chamber. It helps prevent the formation of localized hot or cold spots and ensures consistent growth conditions for the samples.

How can contamination be prevented in an incubator?

Answer: Contamination can be prevented in an incubator by implementing good laboratory practices, such as regular cleaning and disinfection of the chamber, using sterile techniques when handling samples, and utilizing air filters and proper sealing mechanisms to minimize the entry of external contaminants.

What is the role of an incubator’s control panel?

Answer: The control panel allows users to set and adjust the parameters such as temperature, humidity (if applicable), and other settings of the incubator. It provides a user-friendly interface for controlling and monitoring the conditions inside the incubator.

What is the recommended calibration and validation process for an incubator?

Answer: It is recommended to calibrate and validate an incubator periodically using traceable temperature and humidity sensors. This ensures the accuracy and reliability of the incubator’s temperature and humidity readings, providing confidence in the experimental results.

How should an incubator be maintained?

Answer: Regular maintenance of an incubator is essential to ensure its optimal performance. This includes cleaning the chamber, checking and replacing air filters, verifying temperature and humidity accuracy, and scheduling periodic calibration and validation procedures as per the manufacturer’s guidelines.

1 thought on “Useful Incubator and its Principle 2023”