A planetary mixer is a versatile and efficient blending device used in various industries, including food processing, pharmaceuticals, cosmetics, and chemicals. Its unique design and working principle enable precise mixing and uniform blending of ingredients. The working principle of a planetary mixer involves a central agitator, typically equipped with multiple mixing blades or paddles. This agitator rotates on its own axis while simultaneously revolving around the center of the mixing bowl or vessel. This dual-motion creates a thorough blending action, ensuring all ingredients are uniformly combined.

The construction of a planetary mixer typically includes a sturdy base that houses a powerful motor responsible for driving the agitator’s rotation. The mixing bowl or vessel is usually made of stainless steel to maintain cleanliness and durability. The central agitator is securely attached to the motor shaft, allowing for efficient transmission of rotational power.

Planetary mixers come in different sizes, ranging from small laboratory-scale models to large industrial ones, catering to diverse production requirements. They offer flexibility in adjusting rotational speed, allowing users to customize the mixing process based on the specific needs of the ingredients being blended.

Planetary mixer principle

The principle of a planetary mixer revolves around a unique combination of rotating and orbiting motions to achieve efficient and thorough mixing. This mixing principle allows for precise blending of ingredients, ensuring uniformity and consistency in the final product.

The central element of a planetary mixer is the agitator, which is equipped with multiple mixing blades or paddles. This agitator is positioned on a motor-driven shaft that rotates on its own axis while simultaneously orbiting around the center of the mixing bowl or vessel.

As the central agitator rotates, the mixing blades or paddles move through the ingredients, creating a sweeping action. This rotational motion helps to disperse and incorporate the ingredients evenly, promoting thorough mixing. Simultaneously, the orbiting motion of the agitator around the mixing bowl’s perimeter ensures that all areas of the bowl are covered, preventing any unmixed pockets.

The combination of rotating and orbiting motions in a planetary mixer allows for optimal ingredient blending and homogenization. The sweeping action of the mixing blades and the coverage of the entire mixing bowl result in consistent and uniform mixing, ensuring that all ingredients are thoroughly combined.

The principle of a planetary mixer offers several advantages. It allows for efficient and precise mixing of a wide range of viscosities, from liquids to thick pastes. The dual-motion mechanism ensures that even delicate or sensitive ingredients are blended gently, minimizing any potential damage or alteration to their properties.

Planetary mixers are widely used in various industries, including food processing, pharmaceuticals, cosmetics, and chemicals. Their versatile and efficient mixing principle makes them suitable for applications such as dough kneading, cake batter mixing, cream blending, and powder dispersion.

Planetary mixer principle construction and working

The principle of a planetary mixer involves the use of a central agitator that rotates on its own axis while simultaneously orbiting around the center of the mixing bowl or vessel. This dual-motion mechanism allows for thorough blending and mixing of ingredients. The rotating motion of the agitator ensures proper dispersion and incorporation of the ingredients, while the orbiting motion covers the entire surface area of the bowl, ensuring uniformity in the mixture.

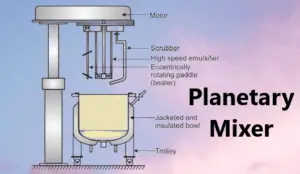

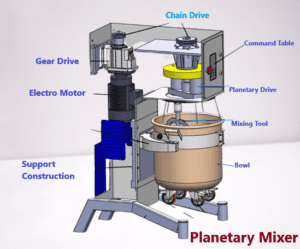

Construction: A planetary mixer consists of several key components. These include:

- Mixing Bowl or Vessel: Typically made of stainless steel, the mixing bowl serves as the container for the ingredients. It is designed to withstand the rigors of mixing and is available in various sizes to accommodate different batch volumes.

- Central Agitator: This is the heart of the planetary mixer. The central agitator is attached to a motor-driven shaft positioned in the center of the mixing bowl. It is equipped with multiple mixing blades, paddles, or other types of agitating tools. The design of the agitator depends on the specific application and the consistency of the ingredients being mixed.

- Motor and Gear System: The motor is responsible for driving the rotation of the central agitator. It provides the power needed for the mixing process. A gear system is often incorporated to transmit the motor’s rotational force to the central agitator efficiently.

Working: When a planetary mixer is in operation, the central agitator starts rotating on its own axis while simultaneously orbiting around the center of the mixing bowl. This dual-motion action ensures that the mixing blades or paddles sweep through the ingredients, creating a thorough mixing and blending process. The ingredients are continuously folded, kneaded, and dispersed, resulting in a homogeneous mixture.

The mixer’s speed and duration can be adjusted based on the specific requirements of the ingredients being mixed. This flexibility allows for precise control over the mixing process, ensuring consistency and uniformity in the final product.

The planetary mixer’s construction and working principle make it suitable for a wide range of applications. It is commonly used in industries such as food processing, pharmaceuticals, cosmetics, and chemicals, where precise and efficient mixing is crucial.

You may also read Rapid Mixture Granulator (RMG)

Components and its uses of planetary mixer

| Component | Uses |

|---|---|

| Mixing Bowl or Vessel | Holds ingredients during the mixing process |

| Provides a space for thorough blending and uniform mixing | |

| Central Agitator | Equipped with mixing blades, paddles, or agitating tools |

| Sweeps through the ingredients, promoting dispersion and blending | |

| Motor | Provides power for driving the rotation of the central agitator |

| Enables efficient mixing and blending of ingredients | |

| Gear System | Transmits rotational force from the motor to the agitator |

| Ensures smooth and controlled mixing operations | |

| Control Panel | Allows adjustment of mixing speed and duration |

| Provides precise control over the mixing process | |

| Safety Features | Overload protection |

| Emergency stop button | |

| Safety interlock |

Planetary mixer diagram

Applications of the planetary mixer

| Industry | Application |

|---|---|

| Food Processing | Dough kneading for bread, pizza, and pastry production |

| Mixing cake batters, cookie dough, and icing | |

| Blending sauces, dressings, and marinades | |

| Emulsifying mayonnaise and other creamy products | |

| Pharmaceuticals | Compounding creams, ointments, and gels |

| Blending powders and granules for medication | |

| Homogenizing suspensions and solutions | |

| Mixing active pharmaceutical ingredients (APIs) | |

| Cosmetics | Formulating creams, lotions, and emulsions |

| Blending foundations, lipsticks, and makeup products | |

| Mixing fragrances, essential oils, and botanical extracts | |

| Incorporating colorants and pigments | |

| Chemicals | Creating specialty formulations and mixtures |

| Homogenizing adhesives, coatings, and sealants | |

| Blending polymers, resins, and compounds | |

| Dispersing pigments, dyes, and additives |

Planetary mixer vs Spiral mixer

| Features | Planetary Mixer | Spiral Mixer |

|---|---|---|

| Mixing Principle | Rotating and orbiting motion | Rotating motion |

| Mixing Action | Thorough and uniform blending | Gentle kneading and folding |

| Bowl Capacity | Usually available in various sizes | Typically larger bowl capacity |

| Mixing Speeds | Multiple adjustable speed settings | Effective gluten development in the dough |

| Suitable for | Wide range of viscosities and ingredients | Bread dough and heavy dough preparations |

| Application | Versatile, used in various industries | Primarily used in bakeries for bread mixing |

| Mixing Efficiency | Efficient mixing and uniform results | Effective gluten development in dough |

| Cleaning and Maintenance | Easy to clean and maintain | Requires thorough cleaning due to spiral design |

| Cost | Generally higher cost due to versatility | Lower cost, specialized for specific applications |