The objective of this Standard Operating Procedure for Breakdown Maintenance of Equipment is to outline the steps and guidelines for conducting breakdown maintenance on equipment or machines to quickly restore their functionality and minimize downtime.

SOP for Breakdown Maintenance of Equipment /Machine

- OBJECTIVE:

- To lay down a procedure to be followed for maintenance of any equipment/ machine installed in case of any breakdown.

- This procedure is applicable to all the equipment/machine installed

- RESPONSIBILITY:

- Technician / Executive Engineering & Maintenance shall be responsible for the performing maintenance of the equipment as per Breakdown Maintenance of Equipment.

- Executive Engineering & maintenance shall be responsible for the preparation and compliance of SOP.

- ACCOUNTABILITY:

- Head of department- Engineering & Maintenance shall be accountable for the SOP of Breakdown Maintenance of Equipment.

- DEFINITIONS:

- Nil.

- PROCEDURE:

- In case of any breakdown of any equipment / machine, the user department shall inform the engineering department through a duly filled “Breakdown intimation memo”, and clarifying the nature of failure .i.e. electrical/mechanical/Instrumentation/others.

- In case, any breakdown occurred in Engineering Equipment shall be handled as per Breakdown Intimation Memo, Format No.(SOP/EN/XXXYYY).

- The Manager – Engineering & Maintenance or concerned representative shall receive the “Breakdown intimation memo” as per Format No. SOP/EN/XXXYYY – from the concerned department.

- The Manager – Engineering & Maintenance or concerned representative shall then issue a duly signed “UNDER MAINTENANCE” label as per Format No. SOP/EN/XXXYYY (Refer Appendix 1), for the said instrument/ equipment.

- Technician– Engineering & Maintenance department shall affix the “UNDER MAINTENANCE” label on the equipment / machine.

- Based on the type of breakdown the Manager – Engineering & Maintenance shall then either assign the responsibility for carrying out the maintenance of the said equipment/ instrument to the Executive or Technician– Engineering & Maintenance or else call the respective Service engineer of the concerned equipment / machine for maintenance.

- As per the nature of breakdown concerned officer /technician /service engineer shall visit the equipment and use the dedicated tools present in that area / equipment in order to prevent any cross contamination. In case if any rarely needed tool is required that should be verified by QA for its cleanliness before taken in use.

- The Technician/ Executive shall disconnect all the utility supplies to the equipment / machine, before starting the maintenance work.

- The Technician/ Executive shall then carry out the maintenance of the equipment / machine by referring the equipment manual and drawings (if required).If requires any spares make indent for the same and get approved from higher authorities.

- After completion of the maintenance, Technician/ Executive shall restore the utility services to the said instrument/ equipment and take a working trial of the equipment / machine in the presence of User department.

- After successful trial, he shall hand over the machine to the user department take the sign of the concerned person on the memo. He shall also remove the “UNDER MAINTENANCE” label.

- The Break down shall be evaluated by QA and accordingly further CAPA /Impact assessment shall be recommended.

- Note: In case the Service engineer of the said equipment / machine is called upon for rectification of the breakdown, then he shall carry out the maintenance in the presence of Technical assistant/ Executive – Engineering & maintenance. After completion of maintenance he shall take a trail in the presence of Technician/ Executive and the User department. After completion of successful trial the instrument/ equipment shall be handed over to the user department and he shall sign on the breakdown memo. The TECHNICIAN/ Executive – Engineering & maintenance shall then remove the “UNDER MAINTENANCE” label from the instrument.

- The Technician shall submit the signed Breakdown memo to the Executive – Engineering & Maintenance.

- The Executive – Engineering & Maintenance shall then enter the details of the maintenance performed in the equipment history card.

- The intimation memo shall be filed in a Record file.

- Breakdown of Utility Machine:

- In case of any breakdown in the utility area machine, the operator shall check for the possible cause of problem.

- If a major problem is found he shall inform Manager – Engineering and Maintenance about the breakdown.

- The manager – engineering & maintenance shall then inform the affected user departments about the breakdown.

- The operator shall then affix “UNDER MAINTENANCE” tag on the said machine.

- The operator/ executive – engineering and maintenance shall then carryout the maintenance work.

- The operator/ executive shall ensure that all the utilities supplies to the machine are disconnected before carrying out the maintenance.

- After the maintenance is over the operator shall take a running trial of the machine.

- On successful completion of the trial the operator shall remove the “UNDER MAINTENANCE” label and then inform the Manager – Engineering & maintenance.

- The manager- engineering & maintenance shall in turn inform all the concerned user departments.

- The operator/ Executive shall make the entry of the maintenance performed in the equipment history card.

- ABBREVIATION:

- CRF No. : Change Request Form Number

- SOP : Standard Operating Procedure

- REFERENCES :

- Nil

- DISTRIBUTION LIST:

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES:

- Breakdown Intimation Memo : SOP/EN/XXXYYY

- Under Maintenance Label : SOP/EN/XXXYYY

Breakdown Maintenance of Equipment /Machine Memo

| BREAKDOWN INTIMATION MEMO |

| Equipment/Instrument Name | Location | ||||||||

| Equipment /Instrument ID | Date | ||||||||

| Nature of breakdown: Electrical/ Mechanical/Instrumentation/Civil/other | |||||||||

| Description of Breakdown: | |||||||||

| Initiated by: | Name: | Sign /date: | Time: | ||||||

| Reviewed By: (QA- Department) | Name: | Sign/Date : | Time: | ||||||

| Intimation Received By: (Engineering –Department) | Name : | Sign/Date : | Time: | ||||||

| Brief on job carried out/Spare Used (After completion of work): | |||||||||

| Breakdown Completed By: (Engineering- department) | Name: | Sign/date: | Time: | ||||||

| Breakdown type: | Repair/ Replace/Modification/ other | Date of completion: | |||||||

| User comments ( if any): | |||||||||

| Checked by : (Initiating department): | Name : | Sign /date: | |||||||

| Comments By (QA): | |||||||||

| Breakdown Evaluated by (QA): | Name : | Sign/date: | |||||||

| Remarks | |||||||||

| Sign/date: | Time: | ||||||||

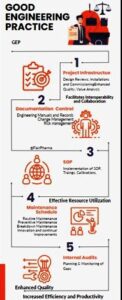

You may also read about Good Laboratory Practices (GLP)