SOP for Operation of Brine Chiller is to establish a standardized procedure for the safe and efficient operation of a brine chiller, ensuring proper cooling of brine solutions for industrial processes while maintaining equipment integrity and personnel safety.

SOP for Operation of Brine Chiller

- OBJECTIVE:

- To lay down a procedure for the operation of Brine chiller.

- SCOPE:

- This procedure applicable for operation of Brine chiller installed.

- RESPONSIBILITY:

- Technicians/Operator-Engineering shall be responsible for proper operation as per SOP.

- Engineering – Head shall be responsible for reviewing the SOP and for the proper execution of operation of Brine chiller.

- User – To initiate Brine Chiller operation Intimation Memo as per the requirements

- ACCOUNTABILITY:

- Quality Assurance – Head shall be accountable for the SOp for Operation of Brine Chiller.

- DEFINITIONS:

- Nil.

Procedure for Operation of Brine Chiller

Preparation of Brine Solution.

- Brine Solution Preparation for Initial Makeup.

- Prepare the solution as per ratio of 30% propylene glycol with soft water for the temperature of the solution at 2.0–8.0ºC.

- Close the outlet valve of the brine preparation tank and put the 30 Ltr of propylene glycol in the brine preparation tank and then makeup the tank upto 70 Ltr. with softwater with the help of bucket.

- After preparation of solution, open the outlet valve of the brine preparation tank and makeup the brine in the brine solution tank of the Brine chiller.

- Repeat the step 6.1.1.2 and 6.1.1.3 till the brine solution tank filled.

- Note:

- User department person will initiate the brine chiller operation intimation memo (Format No. (SOP/EN/XXXYYY) to BMS operator/shift in charge to start and stop the brine chiller.

- Starting Procedure.

- Check the brine solution level in the brine solution tank.

- Check the availability of the power supply.

- Open the valve of supply pump and recirculation pump.

- Set the temperature of the chiller as per production requirement but not less than 0ºC.

- Before switching on the cooling tower pump check level of water at cooling tower sump.

- Start the cooling tower fan, cooling tower pump, chilled water supply pump and chilled water Recirculation pump.

- Start the compressor.

- Check the status in the chiller display and ensure that “UNIT IS LOADED” and cool mode is on.

- Check the status of the chiller at input M-14 selection display.

- Record chilled water in and water out temperature at input M-1 and M-2.

- Record suction pressure and discharge pressure at input M-3 and M-4.

- Record suction temperature and discharge temperature at input M-5 and M-6.

- Record the load current value at input M-12.

- Stopping Procedure.

- BMS operator/Shift in charge shall inform the HVAC operator/technician to stop the chiller. as per the Brine chiller operation intimation memo.

- Stop the compressor from selector switch.

- After minimum 3 minutes stop the cooling tower fan, cooling tower pump, chilled water supply

- Pump and chilled water recirculation pump.

- Close the valve of supply pump and recirculation pump.

- Check the status of the chiller at input M-14.

- ABBREVIATIONS

- SOP – Standard Operating Procedure

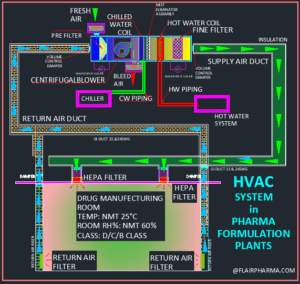

- HVAC – Heating ventilation and Air conditioning.

- BMS – Building Management System

- REFERENCES

- Nil

- DISTRIBUTION LIST

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES

- Chiller Log Book – HVAC SOP/EN/XXXYYY

- Brine chiller intimation memo SOP/EN/XXXYYY

BRINE CHILLER LOG BOOK – HVAC

Date: -_________________

| Time | Suction Pressure | Discharge Pressure | Chilled Water inlet temp | Chilled Water outlet temp | Suction Temp. | Discharge Temp. | Chilled water set point | Load Current | Operator Sign | Remarks | |

| Start | Stop | Psi | Psi | ° C | ° C | ° C | ° C | ° C | Amp | ||

BRINE CHILLER OPERATION INTIMATION MEMO

Department:…………………………

| Intimation given by: | Name : | Sign/ date: | Time: |

| Duration for chiller Activity. (Date\Time) | From: | To: | |

| Reviewed By: HOD/Shift In charge (Initiated Department) | Name: | Sign/ date: | |

| Intimation Received By: (Engineering –Department) | Name : | Sign/Date : | Time: |

| Chiller Start Time | Sign/ date: | ||

| Chiller stop Time | Sign/ date: | ||

| Remark if any: Sign/Date: Sign/Date: (Engineering Department) (Production Department) | |||

You may also read about Good Laboratory Practices (GLP)