Tablet Compression Machine or tablet press is the equipment that is widely used in every pharmaceutical formulation plant to make an oral solid dosage form (tablet form) of the drug. In the below article, we discussed the working principles, major components, and all technical details which are considered by the formulation plant.

Principle and Working of Tablet Compression Machine:

The main principle of the tablet compression machine is hydraulic pressure. Tablet compression is a device that compresses the powder or granules into uniform weight and size tablet or shape. This machine used its punches and die with great force to fuse the material together and form a tablet.

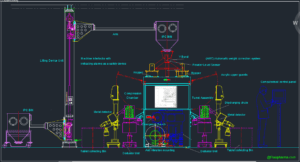

Major Components of compression system:

- Hopper

- Feeder System

- Punches system

- Dies system

- Turret

- Cam tracks

- Filling station and weight control

- Rollers

- Ejection Cam

- Take off Blade

- Discharge Chute

Process of Compression machine to generate tablets:

Filling: Granules or powder fill through IPC with the help of a lifting device, or in current practices Granules or powder by the vacuum system. Granules flow to compression tools i.e., die, punch, and cavity which makes tablets with the help of a lower punch.

Metering: The process of removing extra granules or powder from the turret. Metering is responsible for controlling the Height of the lower punch, which helps in controlling the volume of granules and the Automatic weight control will make the exact dose.

Compression: Formation of tablets with the help of upper and lower punches by pressing within the die.

Ejection: The technique of removing tablets from the die by forcing a lower punch.

Turret Tooling:

Tooling is a setup of punches and dies for the compression of tablets on the machine is called tooling.

There are different types of turret tooling as follows:

| Type of Tooling | Punch Diameter | Die Diameter mm/inch | Punch Length | Max Tab. Size |

| B | 19 mm | 30.05 / 1.187 | 133 | 16/19 |

| D | 25.5 mm | 38.1 / 1.50 | 133 | 25/25 |

| BB | 19 mm | 24 / 0.945 | 133 | 13/24 |

| DB | 25.4 mm | 30.15 / 1.187 | 133 | 19/19 |

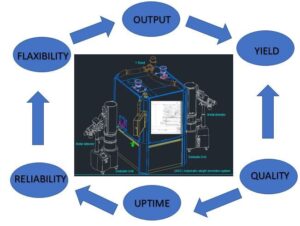

The main feature to be considered when you will be going to buy a new compression machine:

- Choose a machine with high mass and a study design.

- Make of the Compression Machine.

- Interchangeable turret.

- Turret Tooling.

- Layering: Bilayer/ Mono layer or Monolayer with Bilayer facility.

- Single rotary / Double rotary.

- The number of stations.

- Max capacity of Pre / Main compression force (in Kn) 60 kN / 60 kN Pre and Main Compression Force as std.

- Pitch Circle Diameter.

- Machine Dimensions.

- MOC of Cams and all other parts.

- Upper punches should be covered to avoid dust accumulation on punches.

- Sensor with alarm interlock to detect punch jamming.

- Oil lubrication system for lower /upper punches, cam Yes, 4-level Oil Lubrication for upper punches. Lower punches, punch heads, and ejection cam.

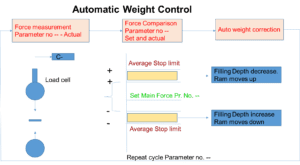

- The machine shall be provided with an inbuilt automatic weight control system (AWC).

- AWC i.e. Weight is controlled in relation thru’ Compaction Force control. (CFC).

- The machine has an Autosampler facility.

The Control panel (IPC) having 21cfr part 11 complies and has facilities like Audit trail, Alarm history, Login / Log out data, Operation history, and Pressure data report. Audit trail in terms of Event Change Report, Batch Recipe, Batch End report, Machine Stop Alarms Report, Rejection report, compression mean values

- Turret Assembly changeover should be possible in 2-4 hours or minimum side.

- Virtually toolless design.

- Multiple turret formats give optimum production capacity for each tablet size/shape.

- Keep a spare set of change parts Interchangeable turret design offers maximum flexibility and hence optimized investment.

The followings are also the key points:

- Fully automatic weight control

- All process parameters set through

- HMI touch screen or IPC

- cGMP compliant to FDA Expectations

- 21 CFR 11 compliant

- CE certified

Certification & Documentations:

- GA Drawing & P&ID, Complete set of Top, Side & Elevation view.

- Ladder logic drawings.

- Motor certificates along with a flameproof certificate.

- MOC certificates of all contact & major non-contact parts including gaskets.

- Certificate of filter bag, pressure test certificate, or each component certificate.

- Complete set of DQ, and IQ Documents.

- All documents are as per URS

Best Manufactures of Tablet compression Machine:

World wide there are many manufacturers are there for tablet compression Machines, Some of the well-known manufacturers are:

- Sejong.

- Fette Compacting

- Korsch Machine

- Parle HATA

- Bosch Manesty

- Cadmech

- Honga

- Karnavati (IRM Enterprises Pvt. Ltd.)

- Chamunda

The cost of the compression machine varies as per the output of the machine it varies from 50 lacs to 4 cr.

(FAQ)Frequently Asked questions about Tablet Compression Machines:

For more technical details, best equipment vendor comparison, or any documentation. (SOP,DQ,IQ,OQ,PQ etc.) Plase contect:admin@flairpharma.com

2 thoughts on “Principle and Working of Tablet Compression Machine (2023)”