Learn about the importance and methods of tap density tester in powder analysis. Understand how bulk and tapped densities impact quality control, formulation development, and packaging in pharmaceutical and material science industries. A Tap Density Tester is a critical instrument used in pharmaceutical and material science laboratories to determine the bulk and tapped densities of powdered samples. These measurements are essential for understanding the physical properties of powders, which can significantly impact their handling, packaging, and application.

Understanding Bulk and Tapped Densities

Bulk Density refers to the mass of an untapped powder sample divided by its volume, including the void spaces between particles. It is influenced by the particle size distribution, shape, and the arrangement of the particles. The bulk density provides insights into the powder’s flow properties and compaction behavior.

Tapped Density is obtained after the powder sample is mechanically tapped or vibrated. This process reduces the volume of the powder by filling the void spaces, resulting in a higher density measurement. The tapped density is crucial for understanding the powder’s compressibility and stability.

Importance of Tap Density Testing

Tap density tester helps in:

- Quality Control: Ensuring the consistency and quality of powdered products.

- Formulation Development: Aiding in the development of pharmaceutical formulations by providing data on powder flowability and compaction.

- Packaging: Optimizing packaging processes by understanding the powder’s bulk and tapped densities, which affects the amount of powder that can be packed in a given volume.

Methods of Determination

The European Pharmacopoeia and the U.S. Pharmacopeia outline several methods for determining bulk and tapped densities:

- Measurement in a Graduated Cylinder: A known mass of powder is introduced into a graduated cylinder, and its volume is measured before and after tapping.

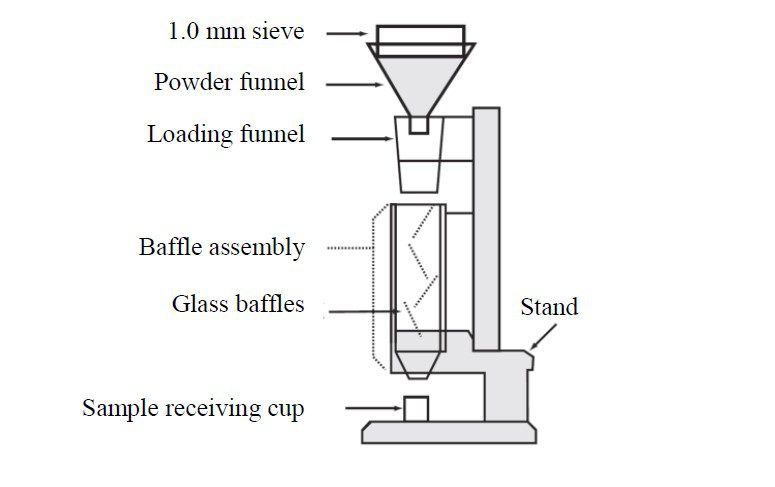

- Measurement in a Volumeter: The powder flows through a baffle system and into a measuring cup, where its volume is recorded.

- Measurement in a Vessel: The powder is allowed to flow into a cylindrical vessel, and its volume is measured after tapping.

Each method has specific procedures and apparatus requirements to ensure accuracy and reproducibility.

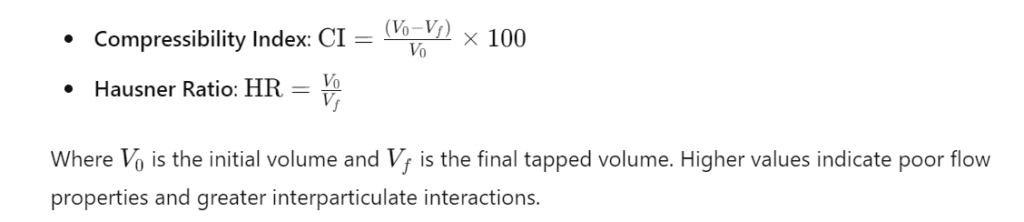

Compressibility Index and Hausner Ratio

The Compressibility Index and Hausner Ratio are derived from the bulk and tapped densities. These indices provide additional information on the powder’s flowability and compaction properties:

Conclusion

The Tap Density Tester is an indispensable tool for characterizing powdered materials. By accurately measuring bulk and tapped densities, it supports quality control, formulation development, and efficient packaging processes in various industries. Understanding and controlling these properties ensures the consistency and performance of powdered products.

Advantages and Disadvantages of the Tap Density Tester:

| Advantages | Disadvantages |

| 1. Accurate Measurement: Provides precise measurements of bulk and tapped densities, essential for quality control and formulation development. | 1. Time-Consuming: The process, especially with multiple tapping stages, can be time-consuming. |

| 2. Standardized Methods: Harmonized with major pharmacopeias (e.g., USP, EP), ensuring consistency and reliability of results across laboratories. | 2. Equipment Cost: High-quality tap density testers can be expensive to purchase and maintain. |

| 3. Essential for Powder Flow Analysis: Critical for understanding powder flow properties, which affect manufacturing processes like tablet compression and packaging. | 3. Operator Variability: Manual methods can introduce variability due to differences in technique among operators. |

| 4. Versatility: Suitable for a wide range of powders and granules across various industries, including pharmaceuticals and materials science. | 4. Potential for Powder Loss: During handling and transfer, there can be a loss of powder, affecting accuracy if not managed properly. |

| 5. Data for Process Optimization: Provides data that can help optimize processes such as mixing, blending, and transport of powders. | 5. Sensitivity to Environmental Factors: Humidity and static electricity can affect powder behavior and measurement accuracy. |

| 6. Non-Destructive Testing: The powder sample remains intact and can be used for further analysis if needed. | 6. Calibration and Maintenance: Requires regular calibration and maintenance to ensure accuracy, which can be resource-intensive. |

| 7. Improved Product Development: Helps in the development of better pharmaceutical formulations by providing critical data on powder behavior. | 7. Limited to Certain Powders: Not all powders may be suitable for this method, especially those prone to caking or agglomeration. |

| 8. Enhanced Quality Control: Enables consistent monitoring and control of powder characteristics, leading to improved product quality. | 8. Requires Skilled Personnel: Accurate measurement and data interpretation require trained and skilled personnel. |

Technical Specifications of the Tap Density Tester:

| Specification | Details |

| Model | Various models available depending on manufacturer (e.g., PT-TD200, TDT Series) |

| Measurement Methods | – Graduated Cylinder Method <br> – Volumeter Method <br> – Vessel Method |

| Tapping Frequency | Adjustable, typically ranging from 100 to 300 taps per minute |

| Tapping Height | Adjustable, typically 3 mm to 14 mm (varies by model) |

| Volume Range | 10 mL to 500 mL cylinders or vessels (model dependent) |

| Volume Resolution | As low as 0.1 mL (model dependent) |

| Timer Range | 0 to 99999 taps (model dependent) |

| Display | Digital LCD or LED display for monitoring parameters and results |

| Power Supply | 100-240 V AC, 50/60 Hz (model dependent) |

| Dimensions | Varies by model, typical dimensions: 300 mm (W) x 400 mm (D) x 500 mm (H) |

| Weight | Approximately 10-20 kg (varies by model) |

| Compliance | Meets USP, EP, and JP standards |

| Data Output | USB and/or RS-232 ports for data transfer and connection to PC |

| Software | Optional software for data analysis and reporting (varies by manufacturer) |

| Temperature Range | Operating range: 10°C to 40°C |

| Humidity Range | 20% to 80% RH (non-condensing) |

| Calibration | Requires regular calibration; calibration weights and tools provided by the manufacturer |

| Accessories | Includes graduated cylinders, tapping platform, funnel, and other necessary accessories |

| Warranty | Typically 1 to 2 years, depending on manufacturer |

Frequently asked Questions (FAQ’s)

What is Tap Density Function?

Answer: Tap density function is a measure of the bulk density of a powder after it has been compacted by tapping. It is used to determine how much space a powder will occupy under specified conditions, providing insights into its packing efficiency and flowability.

How to Test Tapped Density?

Answer:

- Weighing: Weigh a specified amount of powder.

- Filling: Place the powder into a graduated cylinder or a specialized vessel.

- Tapping: Tap the cylinder or vessel mechanically using a tap density tester, typically with a set number of taps.

- Measurement: Measure the volume of the powder after tapping.

- Calculation: Calculate the tapped density using the mass of the powder and the final volume.

What is the Application of Tap Density?

Answer: Tap density is used in various industries, including pharmaceuticals, materials science, and metallurgy, to:

- Optimize powder handling and processing.

- Ensure uniformity in tablet manufacturing.

- Improve packing and shipping efficiency.

- Determine material properties for quality control.

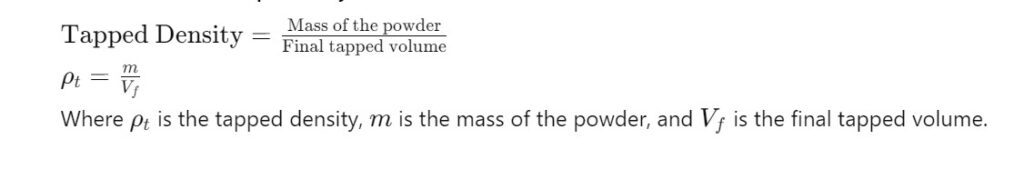

How to Calculate Tap Density?

Answer:

How to Increase Tapped Density?

Answer:

- Particle Size Reduction: Reducing particle size to fill voids more effectively.

- Particle Shape Optimization: Using more spherical particles to improve packing.

- Agglomeration: Encouraging agglomeration to increase density.

- Vibration: Applying additional vibrations to enhance compaction.

How Does a Density Tester Work?

Answer: A density tester works by measuring the volume of a known mass of powder or liquid. It can use different methods, such as:

- Graduated Cylinders: For volume displacement.

- Pycnometers: For precise volume measurement.

- Tap Density Testers: For measuring bulk and tapped densities through controlled tapping.

What is the Test for Density?

Answer: The test for density involves determining the mass and volume of a substance and calculating the ratio:

Density=Volume / Mass

What is the Formula for the Density Test?

Answer: ρ=Vm Where ρ is density, m is mass, and V is volume.

What is the Difference Between Density and Tapped Density?

Answer: Density: The mass per unit volume of a substance.

- Tapped Density: The density of a powder after it has been compacted by tapping.

What is the Formula for Tap Size?

Answer: The term “tap size” usually refers to the size of a threaded hole and is not directly related to tap density. However, in a broader sense, it could be determined using specific engineering standards or formulas based on the application.

What is the Tap Density Standard Test Method?

Answer: Standard test methods for tap density are outlined in pharmacopeias like USP <616> and EP, specifying procedures for measuring bulk and tapped densities using standardized equipment and protocols.

What is the Basic Principle of Density Test?

Answer: The basic principle is to measure the mass and volume of a substance and calculate density as the mass per unit volume.

What is the SI Unit of Density?

Answer: The SI unit of density is kilograms per cubic meter (kg/m³).

What is the Unit for Density?

Answer: Density can be expressed in various units, including kg/m³, g/cm³, and lb/ft³, depending on the context.

What is the Unit of Tap Density?

Answer: The unit of tap density is typically grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³).

What is a Tap Density Battery?

Answer: A tap density battery refers to a battery where the materials used (like powdered cathode and anode materials) are optimized based on their tap density to improve performance and energy density.

What is the Tap Density of Graphite?

Answer: The tap density of graphite varies but is typically around 1.0 to 2.2 g/cm³.

What is the Tap Density of Copper?

Answer: The tap density of copper powder can range from approximately 3.5 to 5.5 g/cm³, depending on the particle size and shape.

Why is Iron Denser Than Graphite?

Answer: Iron is denser than graphite because iron atoms are packed more closely in its metallic crystal structure compared to the layered structure of graphite, which includes significant interlayer spacing.

Is Graphite High or Low Density?

Answer: Graphite has a relatively low density compared to metals, with a typical value around 2.2 g/cm³.