A cleanroom is a controlled environment that is designed to minimize the level of airborne particles, dust, and other contaminants that could potentially compromise the manufacturing or research processes that take place inside the room. Cleanrooms are commonly used in industries such as semiconductor manufacturing, pharmaceuticals, biotechnology, and aerospace, where even small particles or contaminants can have a significant impact on product quality and performance.

Cleanrooms are typically constructed using materials that generate minimal dust or contaminants, such as stainless steel, and are designed to maintain positive air pressure to prevent outside contaminants from entering the room. They also use high-efficiency air filtration systems, such as HEPA (high-efficiency particulate air) filters, to remove particles and other contaminants from the air.

Cleanroom garments, such as gowns, gloves, and masks, are also worn by personnel entering the cleanroom to prevent the introduction of outside contaminants. Cleanroom protocols and procedures are strictly enforced to maintain a controlled environment and ensure that all equipment and materials used in the room are free of contaminants.

How does a clean room work?

A clean room is a controlled environment that is designed to minimize the presence of airborne particles, such as dust, contaminants, and microorganisms. It is typically used in industries such as pharmaceuticals, biotechnology, electronics, and manufacturing, where even small particles can negatively affect the quality and performance of products.

Here’s a general overview of how a clean room works:

- Air filtration: Clean rooms have highly efficient air filtration systems that continuously circulate and filter the air. This typically involves a combination of pre-filters, HEPA (High-Efficiency Particulate Air) filters, and sometimes ULPA (Ultra-Low Penetration Air) filters. These filters remove particles of various sizes, including sub-micron particles, to maintain a high level of cleanliness.

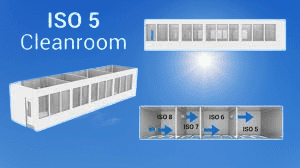

- Positive air pressure: Clean rooms are maintained at a higher air pressure compared to surrounding areas, such as corridors or adjacent rooms. This positive air pressure prevents the entry of unfiltered air from outside and helps to keep contaminants out.

- Controlled airflow: The airflow within a clean room is carefully designed to minimize the presence of particles. Typically, the air is supplied through ceiling-mounted filter units or wall-mounted vents, and it is extracted through floor-level vents or other strategically placed exhausts. This laminar or unidirectional airflow ensures that particles generated within the clean room are quickly removed and that clean air is consistently supplied to the working area.

- Cleanroom garments and equipment: Anyone entering a clean room is required to wear specialized cleanroom garments, such as coveralls, hoods, gloves, and shoe covers. These garments prevent the shedding of particles and help maintain the cleanliness of the environment. Additionally, specific equipment and materials used in the clean room are designed to minimize particle generation.

- Monitoring and control: Clean rooms are closely monitored to ensure that they meet the required cleanliness standards. This includes regular testing of air quality, particle counts, temperature, humidity, and other relevant parameters. Monitoring systems help identify any deviations or potential issues, allowing for timely corrective actions.

By combining these elements, clean rooms create an environment with controlled contamination levels, enabling industries to carry out processes and manufacturing activities with a high degree of precision, reliability, and product quality.

Cleanroom World and its Applications

Cleanrooms are used in a wide range of industries and applications where contamination control is critical. Here are some examples of industries that commonly use cleanrooms:

- Semiconductor manufacturing: The semiconductor industry requires extremely clean environments to manufacture microchips and other electronic components that are free from contaminants that could affect their performance.

- Pharmaceutical and biotechnology: The pharmaceutical and biotechnology industries use cleanrooms to manufacture medicines, vaccines, and other products that require a high level of sterility and purity.

- Medical device manufacturing: Cleanrooms are used to manufacture medical devices such as pacemakers, prosthetics, and surgical instruments, which must be free from contaminants that could cause infection or other complications.

- Aerospace: The aerospace industry uses cleanrooms to manufacture satellites, rockets, and other components that require high precision and cleanliness.

- Optics and electronics: The optics and electronics industries use cleanrooms to manufacture products such as lenses, cameras, and other optical components that require a high degree of precision and cleanliness.

Overall, any industry or application that requires a controlled environment with minimal airborne particles and contaminants could benefit from the use of a cleanroom.

Read about Cleanroom validation

1 thought on “What is a cleanroom”