Many types of Blenders are used for mixing granules of different drugs. That’s why the selection of the design of the blender plays a very important role in every pharmaceutical industry. A blender is used to achieve a uniform blending of dried powder/Granules. there are many types of blenders in pharmaceuticals plant. Here we are discussing the technical aspect and working principles of the blenders.

Working Principle of the Blenders:

In pharmaceutical manufacturing, blending is a crucial unit function because it’s necessary for the uniform distribution of a drug’s ingredients. It is obvious that the amount of active pharmaceutical ingredients (API) in the finished solid dosage form is crucial.

The blender works on the principle of moving or revolving the different types of shaped vessels at a specific RPM of 2RPM to 20 RPM with the help of the electrical motor and gearbox with a supporting piler that holds the revolving vessel. This process is called the blending process of the bulk drug. Generally blending step of bulk drug start after the drying of the bulk drug batch. After blending the batch was directly shifted to the compression machine for the generating tablets.

Types of Blenders:

- V-type Blender:- Design of this blender is V-shaped and this is used for mixing or helping to achieve the uniform mixing of granules of drugs.

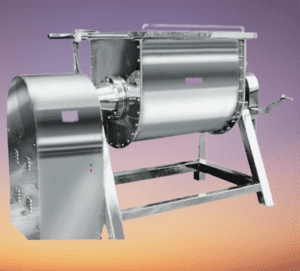

- Mass Blender: – When a product is a lumpy mass, wet or dry granules then we generally, select this mass-type blender.

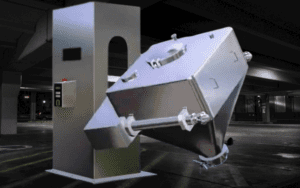

- Octagonal Blender: – It has an Octagonal shaped body and is used for drug granule mixing.

- Vertical Blendr: – Vertical type blender selected in case of mixing of solid drugs, powder, and Granules it gently lifts the material upward direction and blends the same

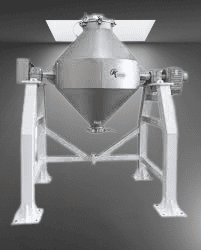

- Double cone Blendr: –This is selected in case of dry powder with heavy and abrasive material.

- Conta blender:- For mass bacheces.

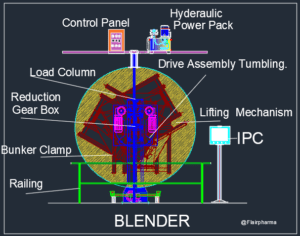

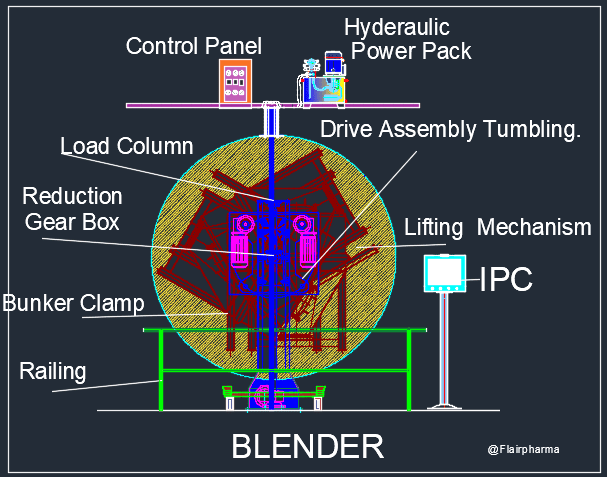

Major Component of different types of Blenders:

- Column, Bunker Clamp.

- Lifting Mechanism.

- Charging port/mechanism.

- Discharging mechanism.

- Drive Assembly Tumbling.

- Electric motor.

- Reduction gear box.

- AC Frequency Drive.

Cleaning Requirements of the Different Types of Blenders:

The Cleaning of the blender is carried out by using a CIP/WIP system. Equipment design must allow for ease of removal of various components in product contact and ease of placement again. All weld joints must be ground & smooth with no crevices and easy cleanability.

Critical parameters:

- Product recipe.

- RPM.

- Time.

- Utility Controls.

- Alarm Set Points.

- S. Tubular Railing at entrance point with gate.

- The gate is interlocked with the drive, through a proximity switch.

- All rotating parts are covered by S.S. Guards.

- 0˚ Stopping, the electromechanical brake.

WIP System For different types of Blenders:

- High-pressure Pump

- Valve Group / Manifold

- Process Piping & Spray Nozzles.

- Compressed Air System

- Electrical Control.

Certification & Documentations:

- GA Drawing & P&ID for FBD, AHU, Exhaust unit, Wet scrubber, Complete set of Top, Side & Elevation view.

- Ladder logic drawings.

- Motor certificates along with a flameproof certificate.

- MOC certificates of all contact & major non-contact parts including gaskets.

- Certificate of filter bag, pressure test certificate, or each component certificate.

- Document for WIP/CIP system for In chamber and duct cleaning document.

- Complete set of DQ, IQ, and OQ.

Manufacturers of different types of Blenders in India

There are many manufacturers of different types of Blenders in India, Some of the well-known manufacturers are:

- Saan Engineers

- Ganson.

- Tapasya.

- Bowen & Archer

- Durma

- Anish Pharma

The cost of the different types of blenders varies as per the output of the equipment it varies from 15 lacs to 60 lacs Indian rupees.

FAQ about the different types of Blender:

What are the different types of blenders and their functions?

Answer: There are several types of blenders used in various industries including pharmaceuticals. Common types include V-blenders, ribbon blenders, double cone blenders, fluidized bed blenders, and high shear mixers. Their functions include mixing powders, granules, pastes, and other materials to achieve uniform blends necessary for pharmaceutical formulations.

What is the working principle of a blender?

Answer:The working principle of a blender involves the rotation of blades or agitators within a container to mix and blend materials together. The blades create turbulence and shear forces that facilitate the blending process.

What is the working principle of blending?

Answer: Blending involves the thorough mixing of multiple ingredients to achieve a homogeneous mixture. This is typically accomplished by applying mechanical force through the rotation or agitation of blending equipment.

What is the working principle of a double cone blender?

Answer: In a double cone blender, the blending process occurs as the double cone-shaped vessel rotates, causing the material inside to move along the vessel walls. This motion facilitates the mixing of the materials, resulting in a uniform blend.

What is the working principle of an octagonal blender?

Answer: Octagonal blenders operate on a similar principle to other tumble blenders, where the container’s octagonal shape promotes efficient mixing as it rotates. The materials inside move in a tumbling motion, ensuring thorough blending.

Do blenders use AC or DC?

Answer: Blenders typically use AC (Alternating Current) motors for their operation.

Do blenders use DC motor?

Answer: While some blenders might use DC (Direct Current) motors, AC motors are more common due to their efficiency and suitability for household and industrial applications.

How many types of blenders are there?

Answer: There are various types of blenders, including V-blenders, ribbon blenders, double cone blenders, fluidized bed blenders, high shear mixers, and more, each with its own unique design and functionality.

Which blender is best in India?

Answer: The choice of the best blender in India depends on factors such as specific requirements, budget, and preferences. Popular blender brands in India include Philips, Preethi, Bajaj, and Maharaja Whiteline, among others.

How many watts is a good blender?

Answer: A good blender typically has a motor with a wattage ranging from 500 to 1500 watts. The wattage of the blender can affect its blending power and performance, with higher wattage generally indicating more powerful blending capabilities.

In India, there are lots of suppliers/machine manufacturers who manufacture Blendrs. We have all technical and commercial comparisons for all. For more detail, you may write to admin@flairpharma.com

You have hit the mark. Thought excellent, it agree with you.

It is remarkable, the helpful information