The Automatic Cartoning Machine and boxing machine are very effective, operate steadily, and serve a variety of functions all in one unit. It is appropriate for packing food, cosmetics, and medications. In pharma 4.0 this plays a major role because the automatic cartonator makes a very good quality product with very high efficiency and high productivity. This cartonator turns a carton board blank into a carton filled with a product or bag of products or a number of items, say into a single carton, engages their tabs or slots to apply adhesive, and closes both ends of the carton entirely sealing the carton after the filling.

The Performance Attributes of the Automatic Cartoning Machine:

- It is capable of automatically creating cartons, opening them (automatically folding the hook and lining to the specifications of the customer), packaging the products, and sealing them.

- This machine uses PLC control. The photoelectricity keeps track of how different components are operating, and if there is an abnormality while it is running, it can instantly halt and indicate the issue for prompt troubleshooting.

- Each transmission system torque overload protector component is installed on the machine board, and the primary drive motor and clutch brake is mounted inside the frame. The main drive motor can be isolated from each transmission component under overload conditions to assure completeness. the machine’s security.

- An intelligent detection gadget is included with the machine. When there is no material, there is no automatic paper box, making it easier to use front-end machinery.

- A complete manufacturing line can be created using this machine alone or in combination with other pieces of machinery.

- The machine has the ability to modify package specs to meet various user needs. It is simple to troubleshoot and customize. It can fulfill the production of tiny batches and several user varieties while also being appropriate for huge volumes of single types.

Different types of Automatic Cartoning Machine:

There are two types of the Cartoning machines:

- Horizontal Cartoning Equipment.

- Vertical Cartoning Equipment.

Working Principle of the Automatic Cartonator Machine:

A Automatic Cartoning Machine that selects one piece from a stack of folded cartons and stands it up before filling it with a product, bag of products, or quantity of products through an open end and sealing the carton by tucking the end flaps in or using glue or adhesive. Using the mechanical sleeve or with the assistance of compressed air, the product can be forced into the carton. Nonetheless, the items are typically physically placed into the carton for many applications. This kind of cartoning machine is frequently used to package foods, confections, medications, cosmetics, and other items. An end load cartoning machine is one that erects a folded carton, fills it with a product or items vertically via an open end, and then closes it by gluing or adhering the end flaps of the carton or by tucking them in. Depending on the size of the company, different types of cartoning machines can be utilized for packaging bottled products, confections, medicines, and cosmetics.

Read More about:

Ampoule Filling and Sealing Machine

Cartonator packing machine its cartoning process and cartoning system

The flow of the cartooning process, and its machine

- Vials / Bottle transfer from the turn table

- Product infeed

- Product transfer to product pocket

- Product Check

- Leaflet Transfer system

- Leaflet pickup

- Carton pick up

- Carton check

- Product pushing

- Carton Closing – tuck in

- Half product insertion check

- Empty carton check

- Product discharge

Cartonator packing machine Description

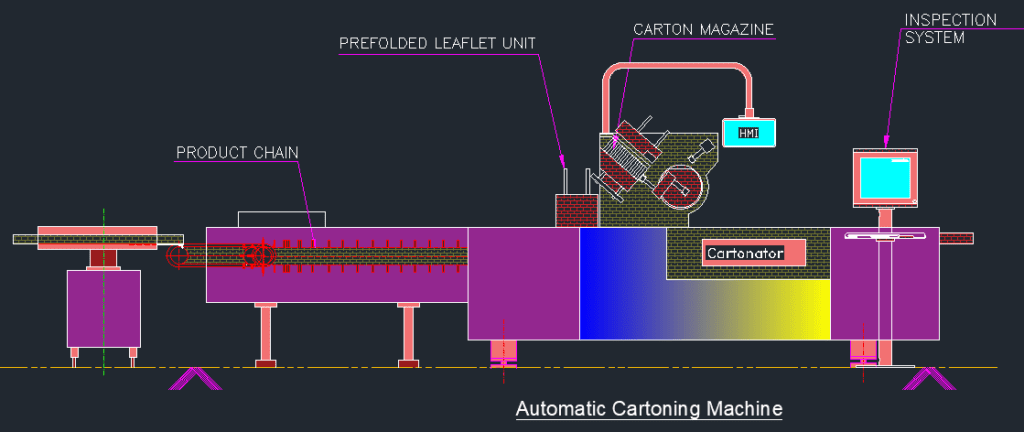

This equipment is a continuous motion Cartoning machine, suitable for the automatic Cartoning of products like Ampoules, Vials/ bottles, tubes, and blisters. The machine meets the need for high-volume production, giving an output of up to 400 cartons/minute depending upon the application. The machine performs the following functions:

- Receive unit product from the upstream machine on the product chain.

- Storing of pre-broken cartons in flat form in the carton magazine.

- Picking up the cartons from carton magazine with rotary pick up system.

- Opening/erecting the carton.

- Rear side flaps folding before product pushing.

- Loading product.

- Both side cartons closing (front & rear sides).

- Discharge either to a bin or to the downstream machine.

The primary functioning sections of the Cartonator Packing Machine:

- The Product Chain for transportation products in Automatic Cartoning Machine :

In this product, the chain transports the product from the feeding area to the pushing area. Product incoming occurs:

•Has 1 pair of roller-supported and double transport chains. Individual product pockets can be adapted to the product size with an adjustment of the chain. The length of the chain extension is depending on the application, upstream integration, and room layout.

Product Chain Extension:

The product chain extension is an additional extension of the product chain. The extension provides additional space between transfer and Cartoning machines for customer-specific use, e.g. for manual product insertion into the production chain or additional product dropping system, etc. - The Carton Chain Transportation System:

The carton chain moves open cartons from the landing to the sealing of the carton. On the carton chain, the following operations take place: • Transfer and final assembly of the cartons- Inserting the leaflet and product

The individual chain pockets can be adapted to the carton size with an adjustment of the chain.

Note: The range of carton length is depending on the chain configuration selected while order finalization. As per the scope of supply, the machine is built with 3 chains.

- Carton Loading Magazine of Automatic Cartoning Machine:

The carton magazine holds various sizes of cartons. Magazine parts can be adjusted easily to accommodate various sizes of cartons with the help of numeric scales. For each size/type of carton, values can be noted down from numeric scales in the setting chart and can be used for reference and changeover. - Carton Pick-up & Transfer System: The folded carton is taken out of the carton magazine by the carton pick-up and transfer system’s sucker arms, and it is then put into the machine’s carton belt. Vacuum pumps and vacuum venturi produce the vacuum that lifts the cartons. The primary method of pick-up is accomplished by suction cups attached to the ends of sucker arms. These rubber cups are flexible and cushioned, making carton handling simple. Together with the carton pick-up system, an integrated carton pre-braking system is offered. Before putting it on the carton chain, this unit is taken out of the carton. The rotating pick-up device is powered by a belt drive and various gears. This thing keeps turning.

- Positioning of Carton of Automatic Cartoning Machine:

A carton pusher that moves cartons towards the product chain from the machine’s backside makes up the carton placement unit.

Two steps are taken to advance the carton:

The carton was half-pushed forward, and then it was fully pushed forward until the flaps met the cell angle’s outside surface. The side flap opener allows for easy product input from the product chain side by opening the side flaps of the carton. - Closed Rear Side Flaps of Automatic Cartoning Machine:

Between pushing the product and loading the carton on the carton chain, the rear side flaps close. The right-side flap is closed by the folding finger, while the left-side flap is closed by the stationary guide. Moving and being propelled by the same force as carton positioning is the folding finger. - Front Side Flaps Opening:

When the backside flap of the carton is folding, the front side flap also opens. Below is the order in which the carton’s front side flaps open.

• The LH side flap is opened by a stationary flap opener.

• A motorized flap opener on the RH side that opens. - System for Pushing Products in Automatic Cartoning Machine

The product is pushed into the carton using the available product-pushing equipment. The Merchandise and Booklet are pushed into the box using product pushers. When the product and carton reach the insertion point, pushing occurs. - Container Closing of Automatic Cartoning Machine :

The carton arrives at the main flaps closing station after the side flaps have closed. In three steps, the front and rear flaps close simultaneously:

Flap placement: By creasing the guide and guiding rod, the closing position is achieved. They are set up so that the locking flap bends with the main flap.

Pre-closing: Tuck-in closers do the pre-closing and full closing. The locking flaps are pushed over the side flaps during pre-closure to lock the carton.

Full closing: Tuck-in closers handle both the pre-closing and the full closing. To lock the carton during pre-closure, the tuck-in closer pushes the locking flaps over the side flaps. - Discharge of Carton in Automatic Cartoning Machine:

The discharge belt receives the closed cartons from the carton chain. These cartons are continuously transported to the following locations, which may be either a collection bin or a line conveyor, by discharge belt.

Two flat belts are part of the discharge belt assembly, which is powered by the main drive. Both belts move at a synchronized speed that is a little faster than the carton chain. - Method for Rejecting Empty Cartons:

The empty cartons are detected by this mechanism, which then removes them from the discharge conveyor. To determine whether there is goods in the container, a sensor is offered. The sensor sends a signal to the control system, which in turn activates an ejection lever driven by a pneumatic cylinder, in the event that the product is not present in the carton. After that, a separate container will be used to collect the rejected carton. - System of Vial Transfer in Automatic Cartoning Machine

This attachment is available for the online transfer of vials from the carton packaging machine’s turntable or upstream equipment. the Turn table, Transfer Conveyor, and Star Wheel are its main assemblies. - Transfer Mechanism for Prefolded Leaflets

To transfer the folded booklet into the carton, this attachment is offered. In the magazine are placed pre-folded pamphlets. - Check for leaflets inside the carton

Before the box is closed, a light sensor that verifies whether the leaflet is within the container is available. If the leaflet is not inserted into the carton properly or is missed, the carton will be returned. - Tower Light in Automatic Cartoning Machine

The machine has a tower lamp put on top that displays the machine’s status in running, stopping, and ready modes. - Discharge of Carton in Automatic Cartoning Machine

The discharge belt receives the closed cartons from the carton chain. - Method for Rejecting Empty Carton

The empty cartons are detected by this mechanism, which then removes them from the discharge conveyor. To determine whether there are goods in the container, a sensor is offered. - System of Vial Transfer in Automatic Cartoning Machine

The turntable’s vials are transferred to the star wheel by a vial transfer conveyor. The vials are transferred at the proper pace thanks to the conveyor’s variable speed motor, which is set to correspond to the star wheel’s peripheral speed. - Transfer Mechanism for Prefolded Leaflets in Automatic Cartoning Machine

To transfer the folded booklet into the carton, this attachment is offered. - Check for leaflets inside the carton in Automatic Cartoning Machine

Before the box is closed, a light sensor that verifies whether the leaflet is within the container is available. If the leaflet is not inserted into the carton properly or is missed, the carton will be returned.

Best Manufacturers (OEMs) of the Automatic Cartoning Machine:

World wide there are many manufacturers are there for Automatic Cartoning Machines, followings are the best well-known manufacturers of the sector:

- ACG Group.

- Elmach Packages Pvt Ltd.

- IMA PG

- IWK technology.

- CAMPAk India Pvt Ltd.

- Lebal Packaging Machinery Co Ltd.

FAQ regarding Automatic Cartoning Machine :

What is principal of Cartonator machine?

Answer: A cartoning machine that selects one piece from a stack of folded cartons and stands it up before filling it with a product, bag of products, or quantity of products through an open end and sealing the carton by tucking the end flaps in or using glue or adhesive.

How does a cartoner work?

Answer: One piece from a stack of folded carton will be picked up by a carton machine, which will subsequently cause the piece to stand up straight or erect. The machine will fold the end flap of the carton or apply glue or adhesive to shut it after filling it with one or more products horizontally through the open end. Although it is not particularly difficult to understand, it can be a little challenging for individuals outside of the cartoning industry to grasp if they haven’t seen one in operation.

What is the meaning of Cartonator?

Answer: The Cartonator is the equipment that packs the semi-finished product & packs it in cartons & to make a good quality product. Automatic Cartoning Machine is one of the best packaging machines.

What is Working Principle of the Automatic Cartoning Machine?

Answer: As per the above details, we briefly discussed the working principle of the Automatic Cartoning Machine so please read the article above.