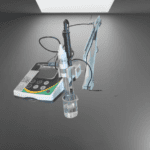

The Karl Fischer Calibration & titrator is a crucial instrument in the field of analytical chemistry, specifically designed for the determination of moisture content in various substances. This sophisticated apparatus provides accurate and reliable results, making it indispensable in industries such as pharmaceuticals, food, and cosmetics.

Operating the Karl Fischer titrator requires a systematic approach. The first step involves preparing the titration vessel by adding the appropriate reagents, typically consisting of a Karl Fischer reagent and a solvent. The sample, which may be a solid, liquid, or gas, is then introduced into the vessel.

Once the sample is in place, the titration process begins. The Karl Fischer reagent reacts with the moisture present in the sample, resulting in a chemical reaction that can be monitored and quantified. This reaction is facilitated by the presence of an indicator or by measuring changes in electrical conductivity.

Karl Fischer Calibration SOP

- OBJECTIVE

- This SOP is applicable for the Operation and Calibration of Karl Fischer.

- SCOPE

- This SOP shall be applicable for the Operation and Calibration of Karl Fischer in the Quality Control Department.

- RESPONSIBILITY

- QC personnel shall be responsible for the Operation and Calibration of Karl Fischer.

- Quality Control Head to ensure compliance with this procedure.

- ACCOUNTABILITY

- QC Head shall be accountable for the SOP.

- DEFINITIONS

- Nil

- PROCEDURE

- Operation:

- Check the electric supply, if required connect the equipment through the UPS line.

- Attach the new/pre-used Karl Fisher bottle to Burette.

- Transfer about 30 to 40 mL of Dried Methanol to the titration Vessel.

- Press “BUBLER” and “Fill” until the burette gets manually filled by the titrant i.e. Karl Fischer reagent.

- Ensure proper fitting of pipe and power supply.

- Switch on the power supply and turn lift side switch to obtain the suitable RPM of the magnetic Bar.

- Select “TITER” mode and start neutralization.

- After the completion of titration instrument will beep.

- Then Add the Weight of the standard /sample (Water) and press key: Start”.

- After the completion of titration, instrument will beep then read the Burette reading & calculate.

- After the completion of test switch off the instrument.

- Cleaning:

- Back flush the reagent present in connecting tube and nozzle by switching on the FLUSH switch.

- Remove the waste solution present in titration vessel with the help of wash bottle.

- Interchange the caps of KF bottle and methanol bottle.

- Rinse the titration vessel with methanol.

- Remove the waste solution.

- Precautions:

- Close the bottle of methanol and KF reagent, tightly when not in use. Moisture present in the Lab may spoil the reagent.

- Shake the bottle of KF reagent when not used for a long time.

- Handle the KF reagent carefully. Follow precautions mentioned by manufacturer.

- Store the KF electrode dry when not in use.

- Rinse the electrode with methanol and store dry.

- Do not keep the electrode dipped in KF reagent/titration vessel after use for long life of electrode.

- Calibrate the flow whenever dispensing tube is changed.

- Make sure the silica desiccant is in good condition.

- Replace the dispensing tube from time to time and make sure it is not leaking.

- Replace the connecting tube after six months to avoid air leaks.

- Calculations:

- Factor Determination:

- KF factor can be determined by weight or by volume.

- By Weight:

- Take some water in the dropping bottle and weigh the bottle. Tare the display so that balance shows 000.0

- Add one drop of water in titration vessel and run the titration. Weigh the water bottle. Display will be showing weight of water drop.

- Factor F1 = Weight of water drop/Volume used of KF

- Factor Determination:

- Operation:

For example, if weight is 35.4 mg and volume is 6.6 mL

F1 = 35.4/6.6 = 5.364

- Determine the factor 2 more times and calculate the average factor.

For example, if weight is 36.2 and volume consumed is 6.8 mL

F2 = 35.8/6.6 = 5.424

- Average Factor (F) = F1 +F2+F3= (5.364+5.324+5.424)/3 = 5.371

- Now weigh the sufficient amount of sample containing 20-35 mg of water and run the titration.

For example weight of sample is say 200.5 mg and volume consumed is 4.6 mL

Factor (mg/mL) x Volume Used (mL) x 100 5.371 x 4.6 x 100

Water % = ———————————————————— = ————————— = 12.32 %

Weight of sample (mg) 200.5

- By Volume: Take accurately 25 µL of water with a syringe or micropipette and inject into the titration vessel and run the titration.

Volume of water (25) x density of water (1)

Factor = ———————————————————————— = mg/mL

Volume of KF used

- Calibration:

- Calibration With Sodium Tartrate Dehydrate.

- Use accurately weighed one drop of water and run H2O factor method.

- The Method is valid if concentration shall be about 5 mg/mL and standard deviation determined consecutively shall not be more than 2.0 %.

- Average of three factors to be considered for calculation of water determination.

- Use 250 mg of accurately weighed Disodium tartrate as a sample.

- Perform the water percentage analysis by selecting % moisture method in three replicates.

- Enter the details in calibration record as per Annexure- I.

- Acceptance criteria: The water content shall be 15.36 % to 15.96 % and the RSD for three samples shall be not more than 2.0 %.

Note: water factor should be determined in once a day before analysis of water content.

- ABBREVIATIONS

- QC : Quality Control

- SOP : Standard Operating Procedure

- KF : Karl Fischer

- RSD : Related Substance Deviation

- QA : Quality Assurance

- REFERENCES

- Instrument operating manual.

- ANNEXURES

- Annexure I : SOP/QCXXX-FYY Calibration Record of Karl Fischer

- Annexure II : SOP/QCXXX-FYY Daily Record of Water Factor

- DISTRIBUTION DETAILS

- SOP shall be distributed to the following departments Quality Assurance and Quality Control and inventory control as per user request.

- REVISION HISTORY

| SOP Version No. | Change Control No. | Reason For Revision | Effective Date |

| 00 | CC | Introduction of new Instrument |

- Annexure I: Calibration Record of Karl Fischer

| Instrument ID | Calibration Due Date | ||||||

| Balance ID | Calibration Due Date | ||||||

| Di sodium Tartrate B. No. | Make | Grade | Valid Up To | ||||

| Sr.No. | Weight of Di sodium tartrate(in gm) A | Volume of K.F Consumed(in ml) B | Water Equivalence factor (in mg/ml) F | Water content W% | Limit |

| 1 | Between 15.60% to 15.72% | ||||

| 2 | |||||

| 3 |

Remarks: – Above Karl Fischer Titrator is suitable for laboratory use.

Annexure II : Daily Record of Water Factor

Instrument Name: _________________ Instrument ID No.: _________________

| Sr. No. | Date | Weight of Water | Volume of KF Reagent Consumed | Factor | Average | %RSD | Done by/Date | Checked by/Date | Remarks |

Application of Karl Fischer

| Application | Description |

|---|---|

| Moisture Content Determination | The primary application of Karl Fischer titrator in QC labs is to determine the moisture content in samples. It provides accurate and precise measurements, enabling quality control of raw materials and finished products. |

| Raw Material Analysis | Karl Fischer titrator is used to analyze moisture levels in incoming raw materials, such as chemicals, excipients, and packaging materials. This ensures the suitability and integrity of the materials used in production processes. |

| Formulation Development | During formulation development, Karl Fischer titrator helps determine the optimal moisture content for product stability and quality. It aids in formulating products with the desired moisture levels to meet regulatory requirements. |

| Product Stability Testing | Karl Fischer titrator plays a crucial role in stability testing by monitoring changes in moisture content over time. This helps assess the product’s shelf life and its ability to maintain quality throughout its intended lifespan. |

| Packaging Integrity Testing | In QC labs, Karl Fischer titrator is utilized to assess the moisture permeability of packaging materials. This ensures that packaging maintains the desired moisture barrier properties, preserving the product’s stability and efficacy. |

| Environmental Monitoring | The Karl Fischer titrator is also used to measure moisture levels in the air, allowing QC labs to monitor and control environmental conditions that may impact product quality and stability. |

| Calibration and Verification | Karl Fischer titrators require regular calibration and verification to maintain accuracy. In QC labs, this includes calibration using certified reference materials and periodic verification checks to ensure reliable results. |

Good Laboratory Practices GLP in Microbiology Laboratory

Finding the Best Tutorials and Tips