Formation of the Biofilms in purified water of pharmaceutical water systems, the threats they pose, and effective strategies for prevention and removal. Learn how to tackle biofilm-associated contamination with advanced techniques like UV light and strong disinfectants.

Biofilm formation in water systems presents a significant challenge, particularly in the pharmaceutical industry. This issue not only poses contamination risks but also leads to equipment degradation and increased operational costs. The biofilm is a resilient matrix formed by bacteria and other microorganisms that adhere to surfaces within the water pipelines. Once formed, it can become highly resistant to removal and disinfection, making it essential to understand its formation process, associated risks, and prevention methods.

What is Biofilm and How Does It Form?

Biofilm is a structured community of microorganisms, such as bacteria, fungi, and other microbes, that embed themselves within a self-produced matrix known as EPS (Extracellular Polymeric Substance). In pharmaceutical water systems, biofilms commonly form on the internal surfaces of water pipelines, where microorganisms can attach and start colonizing. Over time, the EPS matrix shields them from external environmental stressors, including disinfectants and antibiotics.

Biofilm Formation Process:

- Attachment: The biofilm formation starts when free-floating bacteria, such as E. coli and Salmonella, attach to the inner surfaces of water pipelines. The initial attachment is aided by polymucosaccharides secreted by the bacteria, making these organisms difficult to dislodge with gentle rinsing or weak disinfectants.

- Colonization: If not removed, the attached cells multiply and establish colonies. They adhere more firmly to surfaces using pili and flagella, structural components that allow them to form permanent bonds with the surface.

- Development of Slime Layer (EPS): The bacteria secrete a thick, slimy layer, also known as the EPS or slime layer. This matrix is hydrophobic, meaning it repels water, helping the microbes remain firmly attached to the surface. The EPS not only provides structural support but also protects the bacteria from disinfectants and other environmental challenges.

- Maturation and Dispersion: As the biofilm matures, it periodically releases bacteria into the water, leading to continuous contamination. These released microbes can colonize new areas within the water system, perpetuating the biofilm problem.

Types of biofilms in purified water:

In purified water systems, biofilms can form due to the accumulation of microorganisms on surfaces like pipes, tanks, and other equipment. These biofilms are problematic, particularly in industries that require ultra-clean water, such as pharmaceuticals, food and beverage processing, and medical device manufacturing. The types of biofilms in purified water systems are categorized based on the types of microorganisms present, their composition, and the environmental conditions that promote their growth. Below are the key types of biofilms found in purified water systems:

1. Bacterial Biofilms

Bacterial biofilms are the most common type found in purified water systems. These biofilms typically contain a mixture of different bacterial species, which form a matrix of extracellular polymeric substances (EPS) that allows them to adhere to surfaces and resist environmental stress.

A. Gram-Negative Bacterial Biofilms

- Species: Commonly include Pseudomonas, E. coli, Klebsiella, and Legionella.

- Characteristics: Gram-negative bacteria are often found in purified water systems because they are adapted to low-nutrient environments. They have an outer membrane that protects them from disinfectants and harsh conditions.

- Impact: These biofilms pose serious contamination risks, as pathogens like E. coli and Legionella can cause waterborne infections. They are highly resistant to disinfectants, such as chlorine, and can quickly recolonize after cleaning.

B. Gram-Positive Bacterial Biofilms

- Species: Staphylococcus aureus, Bacillus, Streptococcus.

- Characteristics: Gram-positive bacteria tend to form more robust biofilms with thicker layers of EPS. They often survive in low-nutrient environments and are known for their resistance to antibiotics and heat.

- Impact: Gram-positive biofilms can resist many cleaning agents and are difficult to eradicate completely from water systems. Staphylococcus aureus, for example, can survive high temperatures and form resistant biofilms that can persist after routine sterilization procedures.

2. Fungal Biofilms

A. Yeast Biofilms

- Species: Candida species are among the most common yeast forms found in water systems.

- Characteristics: Yeasts are eukaryotic microorganisms that can adhere to surfaces in purified water systems, forming biofilms in conditions where bacterial biofilms already exist or where there is a higher nutrient load.

- Impact: While fungal biofilms are less common than bacterial biofilms in purified water systems, they can still pose serious risks by contributing to contamination. Candida species, for instance, can form resilient biofilms that are difficult to remove with standard disinfection methods.

B. Mold Biofilms

- Species: Aspergillus, Penicillium, Fusarium.

- Characteristics: Mold biofilms are usually found in areas where water systems have not been adequately cleaned, or where water has been stagnant. These biofilms are more likely to develop in parts of the system where humidity levels are high or where water filtration systems are improperly maintained.

- Impact: Mold biofilms can lead to product contamination, especially in industries that require ultra-pure water. They may also release spores into the water, further spreading contamination throughout the system.

3. Algal Biofilms

A. Cyanobacterial Biofilms

- Species: Cyanobacteria, also known as blue-green algae, such as Anabaena and Nostoc.

- Characteristics: Cyanobacteria can photosynthesize and are often found in biofilms in water systems exposed to light. While purified water systems typically operate in closed environments, trace levels of nutrients and light exposure can still promote cyanobacterial growth.

- Impact: Cyanobacterial biofilms are problematic because they can produce harmful toxins, such as microcystins, that contaminate the water. These toxins are dangerous to human health and can lead to major system failures if not addressed early.

B. Green Algae Biofilms

- Species: Chlorella, Ulothrix.

- Characteristics: Green algae can also form biofilms in water systems, especially in sections exposed to light, such as near UV treatment systems. They can adhere to pipe surfaces and cause blockages, as well as degrade water quality.

- Impact: Algal biofilms, while not as common as bacterial biofilms, can disrupt water flow, clog filters, and contribute to biofouling in purified water systems.

4. Mixed-Species Biofilms

Biofilms in purified water systems often consist of a mixture of different microbial species, creating what is known as a polymicrobial biofilm. These biofilms may include combinations of bacteria, fungi, and algae, which interact with one another to form complex, resilient communities.

A. Bacterial-Fungal Biofilms

- Species: Combinations of Pseudomonas (bacteria) and Candida (fungi).

- Characteristics: These biofilms are particularly resistant to cleaning methods because the different microorganisms support each other’s survival. The bacteria provide the structural matrix (EPS), while the fungi contribute to nutrient scavenging and offer additional protection from biocides.

- Impact: Mixed-species biofilms are notoriously difficult to remove because they can survive in harsher environments and exhibit enhanced resistance to disinfectants. Their ability to adapt to environmental stress makes them a significant threat in purified water systems.

B. Bacterial-Algal Biofilms

- Species: Pseudomonas and cyanobacteria.

- Characteristics: Algae provide oxygen and additional nutrients that bacteria need for survival. The bacteria form a protective layer that shields algae from harsh environmental conditions, creating a symbiotic relationship.

- Impact: These biofilms can spread quickly and produce extracellular substances that clog pipes and filtration systems, significantly reducing the efficiency of purified water processes.

5. Sulfate-Reducing Bacteria (SRB) Biofilms

A. SRB Biofilms

- Species: Desulfovibrio, Desulfotomaculum.

- Characteristics: Sulfate-reducing bacteria (SRB) thrive in anaerobic environments, which can be found in the lower parts of water systems where oxygen is limited. These bacteria reduce sulfate to hydrogen sulfide (H₂S), which can cause significant corrosion in metal pipes.

- Impact: SRB biofilms are particularly damaging to infrastructure. Hydrogen sulfide production can corrode metal surfaces, leading to pipe damage and contamination of the water with harmful byproducts. SRB biofilms are a major concern in systems that use metallic pipes, as they can lead to structural degradation and leaks.

6. Thermophilic Biofilms

A. Heat-Resistant Bacterial Biofilms

- Species: Thermus aquaticus, Geobacillus stearothermophilus.

- Characteristics: These biofilms are formed by heat-resistant bacteria that thrive in high-temperature environments, such as the hot water loops of purified water systems.

- Impact: Thermophilic biofilms are particularly challenging to manage in pharmaceutical and food-processing industries where high temperatures are used for sterilization. These biofilms can survive thermal disinfection processes, leading to persistent contamination risks.

Risks Associated with Biofilm in Water Systems

The presence of biofilms in pharmaceutical water systems can lead to several risks:

- Contamination: Pathogens like E. coli and Salmonella within biofilms can contaminate water, leading to unsafe pharmaceutical products.

- Increased Resistance: Biofilm-associated bacteria exhibit increased resistance to antibiotics and disinfectants. For example, E. coli in biofilms requires 500 times the concentration of amphicillin for effective removal, while Staphylococcus aureus in biofilms demands 10 times more vancomycin.

- Pipeline Damage: Biofilms accelerate corrosion within pipelines, especially when sulfate-reducing bacteria are present. These bacteria produce hydrogen sulfide, which reacts with iron in the pipes, leading to leaks and structural damage.

Challenges in Biofilm Removal

Once established, biofilms are notoriously difficult to remove. Weak disinfectants such as chlorine or ozone are often ineffective against mature biofilms. The EPS matrix provides the bacteria with protection, making them resilient to common cleaning agents. Even after removal efforts, biofilms can re-form rapidly if preventive measures are not consistently applied.

Prevention and Removal Strategies

While removing biofilms from water systems is challenging, several strategies can help mitigate their formation and recurrence:

- Continuous Recirculation: Stagnant water encourages biofilm growth. Keeping the water in continuous recirculation prevents bacteria from settling and attaching to surfaces.

- Avoid Dead Legs: Dead legs, or stagnant sections of pipelines, are hotspots for biofilm formation. Designing water systems without dead legs can significantly reduce the risk of biofilms.

- Surface Smoothness: Microorganisms find it easier to attach to rough surfaces. Ensuring the internal surface of water pipelines is smooth can reduce the likelihood of biofilm attachment.

- Strong Disinfectants: For existing biofilms, a combination of strong acids (like nitric acid) and bases (like sodium hydroxide) is used. These chemicals help dissolve both organic and inorganic matter associated with the biofilm. Following this, strong disinfectants such as hydrogen peroxide are applied to sterilize the system.

- UV Light Technology: Ultraviolet (UV) light can be used to prevent biofilm formation in water systems. UV treatment is highly effective because it damages the genetic material of bacteria, preventing them from reproducing and forming colonies.

Biofilm formation in pharmaceutical water systems presents a multifaceted problem, from contamination to infrastructure damage. Understanding how biofilms form and applying stringent preventive measures is essential to maintaining clean water systems. Incorporating advanced cleaning techniques, such as using strong chemical disinfectants and UV technology, will significantly reduce the biofilm threat, ensuring the safety and integrity of pharmaceutical products.

How to get rid of biofilm in water pipes

Biofilm in water pipes is a persistent problem, especially in industrial settings like pharmaceutical plants, food processing, and even household plumbing systems. It can lead to microbial contamination, health hazards, pipe degradation, and reduced water quality. However, removing biofilm is not a simple process due to its resilient nature and protective extracellular polymeric substance (EPS) matrix. Here are several effective methods to remove biofilm from water pipes:

1. Mechanical Cleaning Methods

A. Flushing and High-Pressure Cleaning

- High-pressure flushing can dislodge biofilm by breaking its physical bond with the pipe walls. Water is pumped through the pipes at high velocities, effectively removing the outer layer of the biofilm and other debris.

- Pigging is a technique often used in industrial pipelines where a flexible plug (pig) is sent through the pipeline to scrape the biofilm off the walls. The mechanical action is highly effective at removing hardened or well-established biofilms.

B. Scrubbing and Brushing

For smaller pipes or accessible systems, manual scrubbing with specialized brushes can be effective. This method physically removes the biofilm by breaking its attachment to the pipe surface. However, it is labor-intensive and usually only suitable for systems that are easy to disassemble.

2. Chemical Cleaning Methods

A. Strong Acid/Base Cleaning

A combination of acidic and alkaline solutions is highly effective in dissolving the organic and inorganic components of biofilms:

- Acid treatment (e.g., nitric acid) breaks down inorganic deposits like calcium, which often trap bacteria within the biofilm matrix.

- Base treatment (e.g., sodium hydroxide) helps to dissolve the organic components of the biofilm, including the EPS that holds the biofilm together.

This two-step method is highly effective in loosening and removing biofilms from water pipes.

B. Oxidizing Disinfectants

Oxidizing agents work by breaking down the cellular structures of bacteria and destroying the biofilm matrix:

- Chlorine is one of the most commonly used oxidizing agents for biofilm removal in water systems. However, biofilms are often highly resistant to low concentrations of chlorine, requiring higher doses for effective removal.

- Hydrogen peroxide (H2O2) is another strong oxidizing agent that effectively penetrates biofilms, breaking down the EPS and killing the embedded microorganisms. When combined with peracetic acid, it becomes even more potent, particularly against bacteria like E. coli and Salmonella.

- Ozone is a powerful oxidizer that can kill bacteria and break down biofilm materials quickly. It is particularly effective when used in combination with other cleaning methods.

3. Thermal Treatment

A. Heat Treatment (Thermal Disinfection)

Heat is an effective method to weaken biofilms and kill the microorganisms within them. By increasing the water temperature to around 60-70°C (140-160°F) for a sustained period, the heat can degrade the biofilm matrix and kill biofilm-associated microorganisms.

This method is often combined with flushing to remove the loosened biofilm material from the pipes.

4. Non-Chemical Cleaning Methods

A. Ultraviolet (UV) Light Treatment

UV light can be used to inhibit biofilm formation and prevent regrowth. UV radiation damages the DNA of bacteria, preventing them from reproducing and forming biofilms. While UV does not physically remove existing biofilms, it’s a powerful preventive measure in water systems where biofilm formation is a recurring problem.

UV light is especially useful in pharmaceutical, medical, and food-processing water systems where chemical disinfectants may not be suitable.

B. Ultrasonic Cleaning

Ultrasonic waves generate high-frequency sound vibrations that disrupt biofilm structure and cause the dislodgment of the biofilm from pipe surfaces. This method is highly effective at weakening biofilms in hard-to-reach areas of the water distribution system. It is commonly used in combination with chemical cleaning for better results.

5. Advanced Biocide and Enzyme Treatments

A. Biocides

Biocides are chemicals specifically designed to kill bacteria, fungi, and other microbes. Certain biocides, like quaternary ammonium compounds (QACs) and glutaraldehyde, are particularly effective at penetrating the biofilm matrix and killing embedded microorganisms. However, biofilms often develop resistance to biocides, so continuous use or improper dosing can lead to diminished effectiveness.

B. Enzyme-Based Cleaners

Enzymes such as proteases and amylases can degrade the biofilm matrix, particularly the EPS, making the biofilm more susceptible to other cleaning methods like mechanical flushing or chemical disinfection. Enzymatic treatments are eco-friendly and have gained traction as a more sustainable method for biofilm removal.

6. Prevention of Biofilm Formation

Once the biofilm is removed, preventing its recurrence is critical. Some key preventive strategies include:

- Continuous water flow: Stagnant water promotes biofilm growth, so ensuring continuous recirculation of water helps prevent microbial attachment.

- Dead leg elimination: Dead legs (stagnant sections of the pipe where water doesn’t flow) should be removed or minimized to prevent biofilm formation.

- Surface smoothing: Rough internal surfaces of pipes encourage biofilm attachment. Using smoother materials reduces the risk of biofilm formation.

- Regular disinfection and cleaning: Routine maintenance using strong oxidizing agents or UV light can help prevent biofilms from forming again after removal.

Biofilm removal from water pipes is a multifaceted process that requires a combination of mechanical, chemical, and non-chemical approaches. Depending on the severity of the biofilm and the system’s design, a tailored approach is needed to ensure effective removal and long-term prevention. Mechanical cleaning, combined with strong chemical treatments like oxidizing disinfectants or acids/bases, remains the gold standard for effective biofilm removal. To prevent biofilm formation, continuous monitoring and regular maintenance are crucial in maintaining the cleanliness and safety of water systems

Frequently Asked Questions (FAQ)

What is a biofilm, and how does it form in water systems?

A biofilm is a colony of microorganisms, such as bacteria, that adhere to surfaces in water systems and produce a protective slime layer (EPS). This layer shields the bacteria from disinfectants, making biofilms difficult to remove. Biofilm formation begins when free-floating bacteria attach to a surface, form colonies, and secrete a matrix that helps them persist.

Why are biofilms dangerous in pharmaceutical water systems?

Biofilms in pharmaceutical water systems can harbor harmful bacteria, such as E. coli and Salmonella, leading to contamination. They are also highly resistant to disinfectants, which makes them difficult to eliminate. Additionally, biofilms can cause corrosion in pipelines, leading to costly repairs and maintenance.

How can biofilm formation be prevented?

Prevention methods include keeping water systems in continuous recirculation, eliminating dead legs, ensuring smooth internal surfaces, and using advanced treatments like UV light. Regular cleaning with strong acids and bases also helps prevent biofilm formation.

What are the most effective ways to remove biofilms from water systems?

To remove biofilms, strong chemical treatments using acids (e.g., nitric acid) followed by bases (e.g., sodium hydroxide) are highly effective. Additionally, disinfectants such as hydrogen peroxide are used to sterilize the system after cleaning. UV light technology is also an effective preventive measure.

Can biofilms form quickly in stagnant water?

Yes, biofilm formation can occur rapidly in stagnant water, as it allows microorganisms the time to attach and colonize surfaces. Continuous water recirculation is crucial to preventing biofilm buildup.

What are the different types of biofilms?

Answer: Biofilms can be classified into different types based on the microorganisms present and the environments they form in:

- Bacterial biofilms: Formed by bacteria such as Pseudomonas and E. coli.

- Fungal biofilms: Composed of fungi like Candida and Aspergillus.

- Algal biofilms: Formed by cyanobacteria or green algae in aquatic systems.

- Mixed-species biofilms: A combination of bacteria, fungi, and algae working in a symbiotic manner.

- Sulfate-reducing bacterial (SRB) biofilms: These produce corrosive byproducts like hydrogen sulfide.

- Thermophilic biofilms: Composed of heat-resistant bacteria in high-temperature environments.

What are biofilms in water?

Answer: Biofilms in water are communities of microorganisms, such as bacteria, fungi, and algae, that attach to surfaces in water systems. These biofilms form protective layers (extracellular polymeric substances or EPS) that shield the organisms from disinfectants and environmental stressors. They can lead to water contamination, reduced water quality, and system corrosion.

What are the biofilms in freshwater?

Answer: Biofilms in freshwater systems typically consist of bacteria, algae, fungi, and protozoa. Cyanobacteria and green algae are common in biofilms found in freshwater environments. These biofilms form on rocks, plants, or man-made structures like water pipelines and can influence nutrient cycling in aquatic ecosystems.

What is biofilm in WFI system?

Answer: Biofilm in a Water for Injection (WFI) system refers to microbial colonies forming on the surfaces of pipes, tanks, and other components in pharmaceutical water systems. These biofilms can cause contamination in ultra-pure water systems, making it challenging to maintain sterility and quality standards.

What is the most common biofilm?

Answer: The most common biofilm is bacterial biofilm, specifically those formed by Pseudomonas aeruginosa and Staphylococcus aureus. These bacteria thrive in water distribution systems and medical environments due to their resistance to disinfectants and antibiotics.

What are the three stages of biofilm?

Answer: The three stages of biofilm development are:

- Attachment: Free-floating microorganisms adhere to a surface.

- Growth and maturation: Cells grow and produce EPS, forming a stable biofilm structure.

- Dispersal: Mature biofilm releases microorganisms into the surrounding environment, spreading contamination.

How many CFU are in WFI?

Answer: In Water for Injection (WFI) systems, the microbial limits are stringent, typically requiring less than 10 Colony Forming Units (CFU) per 100 mL of water.

How do you remove biofilm from water?

Answer: Biofilm removal from water systems involves:

- Mechanical cleaning: Scrubbing or pigging to physically remove biofilms.

- Chemical cleaning: Using strong acids/bases like nitric acid and sodium hydroxide, or oxidizing agents like hydrogen peroxide.

- Thermal treatment: High-temperature water can kill biofilms.

- UV treatment: Disrupts microbial DNA and prevents biofilm formation.

What is biofilm for water treatment?

Answer: In water treatment, biofilms can play both a positive and negative role. While biofilms can cause contamination in water systems, in some cases, they are used in bioreactors for water treatment, where microbial biofilms break down organic waste, remove contaminants, and purify water.

What is the purpose of biofilm?

Answer: The primary purpose of biofilm formation for microorganisms is protection and survival. The EPS matrix shields the cells from environmental stress, disinfectants, and antibiotics, allowing them to survive in harsh conditions. Biofilms also help microorganisms exchange nutrients and genetic material.

What is an example of a biofilm?

Answer: A common example of a biofilm is dental plaque. It forms on the surface of teeth, consisting of bacteria and their byproducts that can lead to tooth decay and gum disease.

What are the microbial limits for WFI water?

Answer: For Water for Injection (WFI), the microbial limit is typically less than 10 CFU per 100 mL and requires water to be free from any endotoxins.

What is biofilm formation in drinking water?

Answer: In drinking water systems, biofilm formation occurs when bacteria and other microorganisms attach to the inner surfaces of pipes, forming colonies that can release pathogens and degrade water quality. Factors like stagnant water, rough surfaces, and nutrient availability promote biofilm growth in drinking water systems.

What are 3 characteristics of biofilm?

Answer:

- Adhesion: Microorganisms attach to a surface.

- EPS production: Biofilms produce a protective extracellular matrix.

- Resistance: Biofilm microorganisms are highly resistant to antibiotics, disinfectants, and environmental stress.

What are the 5 stages of biofilm growth?

Answer:

- Initial attachment: Microorganisms adhere to a surface.

- Irreversible attachment: Cells produce EPS and form a stable attachment.

- Maturation I: The biofilm begins to develop complex structures.

- Maturation II: The biofilm reaches full development, with established channels for nutrient flow.

- Dispersion: Cells are released from the biofilm to colonize new areas.

How do you identify biofilms?

Answer: Biofilms can be identified using:

- Microscopic analysis: Staining and observing under a microscope.

- ATP testing: Detecting cellular activity.

- Surface sampling: Using swabs or coupons to test for microbial growth.

- Genomic sequencing: Identifying microbial species present in the biofilm.

What is the life cycle of a biofilm?

Answer: The life cycle of a biofilm consists of:

- Attachment: Microbes adhere to a surface.

- Growth: Cells divide, produce EPS, and form a matrix.

- Maturation: The biofilm develops complex structures.

- Dispersal: Cells are released to colonize new surfaces.

Is biofilm harmful to humans?

Answer: Yes, biofilms can be harmful to humans. Biofilm-associated infections are more difficult to treat because biofilm bacteria are resistant to antibiotics. Biofilms can also cause contamination in drinking water and medical devices, leading to serious health risks.

How to clean biofilm from a water bottle?

Answer: To clean biofilm from a water bottle:

- Use hot water with soap and a bottle brush to scrub the interior.

- Soak the bottle in a solution of vinegar or hydrogen peroxide.

- Rinse thoroughly with boiling water to kill any remaining bacteria.

How to remove biofilm?

Answer: Biofilm removal methods include:

- Mechanical scrubbing.

- Chemical treatments (acids, bases, oxidizing agents).

- Thermal disinfection (using high temperatures).

- Ultrasonic cleaning to dislodge biofilm.

How many species are in a biofilm?

Answer: A biofilm can contain multiple species of microorganisms, sometimes more than 1,000 different species, including bacteria, fungi, and algae. The diversity depends on the environment and available nutrients.

What is the role of biofilm?

Answer: The role of biofilms is to provide protection for the microorganisms, allowing them to survive in hostile environments. Biofilms also facilitate nutrient exchange and genetic material transfer between cells.

What are the advantages of biofilm?

Answer: Advantages of biofilm formation for microorganisms include:

- Protection from environmental stress and antibiotics.

- Nutrient retention within the biofilm matrix.

- Enhanced communication and cooperation among species.

What are the applications of biofilm?

Answer: Biofilms are used in various applications, including:

- Wastewater treatment: Biofilms break down organic material.

- Bioremediation: They degrade pollutants in contaminated environments.

- Medical research: Understanding biofilms helps in developing treatments for biofilm-related infections.

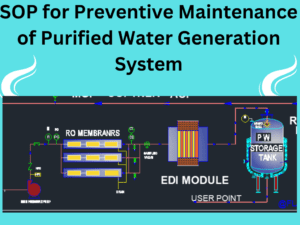

Prevention and Control of Biofilms in Pharmaceutical water systems and Validation of water systems