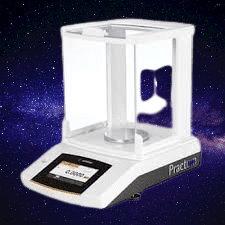

An analytical balance is an essential tool in quality control labs, used to ensure that products meet the required standards. Discover the importance of analytical balances in quality control labs and how they help to maintain the highest levels of accuracy in measurements. Learn about the key features of analytical balances and how they can help to improve the efficiency and reliability of quality control processes.

Analytical balances are essential tools in quality control labs, where they play a critical role in ensuring that products meet required standards. These highly sensitive instruments are used to measure the precise quantities of reagents and samples, helping to maintain the highest levels of accuracy in measurements. With their advanced features such as auto-calibration, anti-static systems, and built-in databases, these balances can significantly improve the efficiency and reliability of quality control processes. By using these balances in quality control labs, manufacturers can ensure that their products meet the strictest standards of quality, safety, and accuracy.

Principle of Analytical Balance

The principle of an analytical balance is based on the law of the lever, where a small weight on one end of the lever can balance a larger weight on the other end. An analytical balance consists of a beam supported on a fulcrum, with a pan hanging from each end of the beam. The sample to be weighed is placed on one of the pans, while calibrated weights are placed on the other pan to balance the sample.

When the sample is placed on the pan, the beam tilts and the pan moves downwards. This movement is detected by a sensitive transducer, which generates a signal that is proportional to the mass of the sample. The signal is then converted into a digital reading and displayed on the balance.

The accuracy of an analytical balance is determined by the sensitivity of the transducer, which is typically a strain gauge or a capacitive sensor. These sensors can detect very small changes in weight, on the order of micrograms or even nanograms, and can provide precise and accurate measurements.

To ensure the accuracy of an analyzing balance, it is important to keep it clean and free of dust, vibrations, and other environmental factors that could affect the measurements. The balance should also be calibrated regularly using standard weights of known mass.

Applications of analytical balance

- Laboratory experiments: Analytic balances are commonly used in chemistry, physics, and biology laboratories to measure precise quantities of reagents or samples.

- Quality control: In manufacturing industries such as food, cosmetics, and pharmaceuticals, analytical balances are used to ensure that products meet quality standards.

- Precious metal and gemstone analysis: Analytical balances are used in the jewelry industry to measure the precise weight of precious metals and gemstones.

- Medication compounding: In pharmacies, analytical balances are used to measure small quantities of active ingredients and excipients to prepare compounded medications.

- Research: Analytic balances are used in scientific research to measure small quantities of materials for various applications.

- Environmental testing: Analytic balances can be used in environmental testing to measure pollutants in soil, water, or air samples.

- Educational purposes: Analytic balances are often used in educational settings to teach students about measurement and accuracy in science.

- Forensic science: Analytic balances can be used in forensic science to analyze trace evidence such as fibers, hair, or powders.

- Veterinary medicine: Analytic balances are used in veterinary medicine to measure precise doses of medications for animals.

- Agricultural research: Analytic balances can be used in agricultural research to measure small quantities of seeds or chemicals for testing and experimentation.

Analytical balance calibration

Analytical balance calibration is a process of checking and adjusting the balance to ensure that it provides accurate and reliable measurements. Here are the general steps to perform an analytical balance calibration:

- Prepare the calibration weights: Obtain a set of certified weights with values close to the maximum capacity of the analytic balance.

- Clean the balance: Use a soft brush or cloth to remove any dirt or dust from the balance pan and surrounding area.

- Warm up the balance: Turn on the balance and let it warm up for at least 30 minutes before starting the calibration process.

- Zero the balance: Press the tare button to set the balance to zero.

- Weigh the calibration weights: Place the calibration weights on the balance pan, one by one, and record the readings.

- Calculate the error: Compare the readings with the expected values of the calibration weights and calculate the error.

- Adjust the balance: Use the adjustment mechanism of the balance to correct any errors found during calibration.

- Repeat the process: Repeat the calibration process if necessary, until the balance provides accurate and consistent readings.

- Record the results: Record the calibration data, including the weights used, the readings obtained, and the adjustments made, in a calibration log or certificate.

It is recommended to perform analytical balance calibration on a regular basis, such as weekly or monthly, depending on the frequency of use and the requirements of the application. It is also important to follow the manufacturer’s instructions and guidelines for proper maintenance and calibration of the analytical balance.

Frequently Asked Questions

What are 5 uses of analytical balance?

Answer:

- Measuring the precise weight of chemicals or samples for experimental purposes in laboratories.

- Conducting quality control in manufacturing processes, such as in the food, pharmaceutical, or cosmetic industries.

- Analyzing precious metals or gemstones for purity and value.

- Conducting research in fields such as physics, chemistry, and biology.

- Compounding medication in pharmacies.

What are the 2 types of analytical balance?

Answer: Types of analytical balance:

- Top-loading analytical balance: typically used for general-purpose weighing and can measure larger samples.

- Microanalytical balance: used for extremely precise measurements, typically weighing samples with a mass of less than 0.1 milligrams.

What is the use of analytical balance in pharmacy?

Answer: Use of analytical balance in pharmacy: Analytical balances are commonly used in pharmacies for compounding medications, which involve combining multiple ingredients to create a specific dosage form. Accurate measurement of each ingredient is critical for ensuring the safety and effectiveness of the final product.

What are the important parts and functions of the analytical balance?

Answer:

- Weighing pan: the platform where the sample is placed.

- Weighing chamber: an enclosed space that protects the balance from external factors that could affect the accuracy of the measurement.

- Load cell: converts the mechanical force of the sample into an electrical signal that can be read by the balance.

- Display: shows the weight of the sample.

- Calibration system: allows the user to calibrate the balance to ensure accurate readings.

The main function of an analytical balance is to provide precise and accurate measurements, which is why it is important to calibrate and maintain the balance to ensure optimal performance regularly.