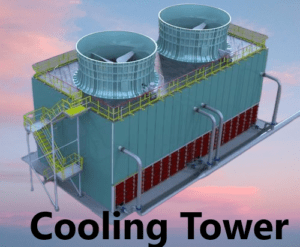

the SOP for Preventive Maintenance of Cooling Towers is to establish a standardized procedure for conducting preventive maintenance on cooling towers, ensuring their efficient operation, prolonging their lifespan, and maintaining optimal heat exchange efficiency.

SOP for Preventive Maintenance of Cooling Towers

- OBJECTIVE:

- To lay down the Procedure for cleaning & preventive maintenance of cooling towers installed on Terrace area .

- SCOPE:

- This SOP is applicable to Preventive Maintenance of Cooling Towers installed on Terrace area of Service area .

- RESPONSIBILITY:

- Technician/ Operator shall be responsible for proper execution of preventive maintenance as per SOP for Preventive Maintenance of Cooling Towers.

- Engineering – Head shall be responsible for reviewing the SOP and for ensuring proper execution of Preventive Maintenance of Cooling Towers.

- ACCOUNTABILITY:

- Engineering – Head shall be accountable for proper implementation of the SOP for preventive maintenance of cooling towers .

- DEFINITIONS:

- Preventive Maintenance of Cooling Towers: Planned and scheduled maintenance activities aimed at ensuring the consistent and efficient operation of cooling towers. These activities include regular inspections, cleaning, lubrication, testing, and adjustments, conducted to prevent potential issues, optimize heat exchange efficiency, extend equipment lifespan, and maintain the overall performance of cooling towers. This proactive approach helps minimize unexpected breakdowns, reduce energy consumption, and ensure the cooling tower’s reliability in heat dissipation processes across various industrial applications and HVAC systems.

PROCEDURE:

- Preventive maintenance shall be executed as per the SOP No.: SOP/EN/XXXYYY – Execution of Preventive Maintenance.

- Ensure that the spare parts are available at the time of preventive maintenance.

Preventive Maintenance of Cooling Towers– Mechanical

- Checking and cleaning of cooling tower basin

- Cleaning of cooling tower basin to be done on every 30±7 days.

- Close main water inlet valve to the sump tank.

- Also close cooling water return valve to stop water return to cooling tower.

- Switch off cooling tower fan.

- Switch off cooling water pumps.

- Open the drain valve of the tank and left water drain off.

- Scrap the internal surface of the tank with the help of brush and allow the water to drain out from the drain valve.

- Dismantle the strainer filter in the outlet of the sump tank and clean it.

- Open main water inlet valve to the sump tank and continue flushing the tank and the pipelines thereof till clear water not comes.

- Checking of valves and pipe fittings

- Check all the Valves, pipe line supports and flanges and tighten them if found loose.

- Check the flanges on pipeline and fittings for leakages.

- If any leakage is present then check the gaskets, if found damaged replace the same and tight the flange.

- Checking shall be done monthly.

- Checking of cooling water circulation pump and sprinkler socket.

- Check the pump for any water leakage, if any leakage is observed then rectify it.

- Visually check the Mechanical seal of the pump for any leakage or damage, If found broken then replace the mechanical seal through a competent technician.

- Lubricate the pump bearing with grease by using grease gun.

- Checking of sprinkler socket for any leakage, tighten them if found loose.

- Checking of sprinkler socket leg fittings and balancing for proper movement of sprinkler.

- Checking shall be done quarterly.

- Checking of cooling tower fan

- Physically Check the cooling tower fan blade for any bending of blades,

- Clean the fan blades if get fouled with dust.

- Check the structural support for the motor.

- Checking frequency shall be done after every six month.

- Checking and cleaning of the fills

- Check the water sprinkler flow pattern

- Physically Check the cooling tower fills for any choking; damaged; if required clean and rectify the same.

- In flow pattern there should not be channel flow; the water should be sprinkle uniformly through the entire cooling tower.

- Checking frequency shall be done after every six month.

- Checking of sprinkler head

- Check the sprinkler head physically for any damage.

- Check the sprinkler head bearings

- Checking shall be done on quarterly basis.

Preventive Maintenance of Cooling Towers– Electrical

- Checking of terminals and wiring

- Ensure that the power supply to the machine is switched off.

- Visually check all the power and control wiring and terminals in the electric panel and on the field instruments.

- Check and ensure by using screwdriver that all the wires are properly tightened.

- Checking shall be done after every six month.

- Checking of motor

- Check the insulation resistance of motor winding with the help of megger.

- Check the phase continuity and winding continuity of motor with the help of multimeter.

- Physically check the motor terminal box and terminal connections.

- Check the voltage drawn by motor with the help of multimeter

- Check the current drawn by motor with the help of tong tester.

- Check the direction of rotation; it should be as per recommended direction.

- Checking shall be done after every six month

- Checking of contactors

- Switch off the main switch on the electrical panel.

- Remove all wires from the contactor.

- Remove the dust from control panel with help of air blower.

- Remove the contactor from the panel and visually check all the contacts for pitting and carbon deposits on the contacts.

- Clean all the contacts with carbon tetra chloride (CTC) or with contactor cleaner.

- Replace the contacts if found damaged or welded.

- Put back the contactor in the panel and connect the wires in their respective panels.

- Check the earthing of the panel body.

- A good earthing shall show less than 2 Volts between the Neutral Wire of the Incoming Power supply and Panel Body.

- Checking of contactors shall be done quarterly.

Post Preventive Maintenance of Cooling Towers Check List

- Whenever any modifications and major works are carried out to the equipment, the same shall be mentioned in the equipment history card as per the respective SOP.

- Connect the equipment main power supply and start the equipment.

- Ensure that the equipment is running smoothly, without any abnormality.

- If any abnormality is observed in the above, same will be attended in co-ordination with User department Head.

- Record the PM details as per the Format No.: SOP/EN/XXXYYY “Preventive Maintenance Checklist & Record for Cooling Tower”.

- ABBREVIATIONS:

- CRF No. : Change Request Form number

- QA : Quality Assurance

- PM : Preventive Maintenance

REFERENCES

- Nil.

DISTRIBUTION LIST:

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request

- ANNEXURES:

- Preventive Maintenance Check List & Record for Cooling Tower : SOP/EN/XXXYYY

Checklist and Records for Preventive Maintenance of Cooling Towers

CHECKLIST & RECORD

| Equipment Name | Location | ||

| Equipment ID | Frequency |

| Check List | Check | Remark |

| Monthly Check List | ||

| Checking and cleaning of cooling tower basin. | ||

| Checking of valves and pipe fittings. | ||

| Quarterly Check | ||

| Checking of cooling water circulation pump for abnormal sound; mechanically seal; lubrication of bearings. | ||

| Checking of sprinkler socket for any leakage, tighten them if found loose. | ||

| Checking of sprinkler socket leg fittings and balancing for proper movement of sprinkler. | ||

| Checking of sprinkler head. | ||

| Half Yearly Check List | ||

| Physically check the cooling tower fan blade for any bending of blades. | ||

| Clean the fan blades if get fouled with dust. | ||

| Checking of terminals and wiring | ||

| Checking of motor. | ||

| Checking of contactors |