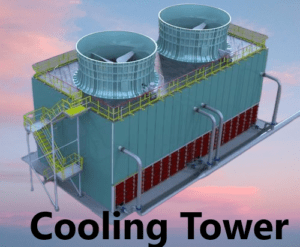

A cooling tower is a specialized structure designed to facilitate the removal of excess heat from industrial processes or commercial buildings. It serves as a crucial component in maintaining optimal temperatures and preventing equipment from overheating. The primary function of a cooling tower is to dissipate heat into the surrounding atmosphere by facilitating the transfer of thermal energy from water or other fluids.

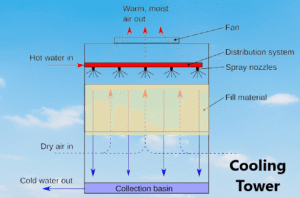

The cooling tower operates on the principle of evaporative cooling, harnessing the natural phenomenon of water evaporation to remove heat. In simple terms, warm water from the industrial process or air conditioning system is directed to the top of the cooling tower, where it is distributed over a series of fill materials. These fill materials are specifically designed to increase the surface area of water exposed to the air.

As the water flows downward through the fill materials, it encounters a stream of ambient air that is simultaneously drawn upwards by fans located at the base or top of the cooling tower. This interaction between the descending water and ascending air creates a counterflow or crossflow pattern, promoting efficient heat exchange.

During the process, a portion of the water evaporates due to direct contact with the air, absorbing heat energy from the remaining water. This evaporation causes a cooling effect, lowering the overall temperature of the water. The cooled water then collects at the bottom of the cooling tower and is recirculated back to the industrial process or air conditioning system, ready to absorb more heat.

How Does A Cooling Tower Work

A cooling tower operates by harnessing the principles of evaporation to remove excess heat from industrial processes or air conditioning systems. The process involves the circulation of water and the exchange of heat with the surrounding air. Let’s explore how a cooling tower works in more detail:

- Water Circulation: The cooling tower receives hot water from industrial processes or air conditioning systems through an inlet pipe. This hot water is then distributed over a series of fill materials within the tower. These fill materials increase the water’s surface area, facilitating efficient heat transfer.

- Air Flow: Simultaneously, fans or blowers located within the cooling tower draw in ambient air and direct it toward the fill materials. The airflow can be either in a counterflow or crossflow configuration. The purpose of this airflow is to promote contact between the air and the falling water.

- Heat Exchange: As the hot water cascades down through the fill materials, it comes into direct contact with the upflowing air. This contact facilitates the transfer of heat from the water to the air. Some of the water evaporates into vapor due to the temperature difference, absorbing heat energy in the process.

- Evaporative Cooling: The evaporation of water into vapor removes heat from the remaining water, resulting in a cooling effect. This cooled water collects at the bottom of the cooling tower, ready for recirculation back to the industrial processes or air conditioning systems.

- Release of Heat: The vapor generated during evaporation and warm air is expelled from the cooling tower through an outlet. This release of heat and moisture into the atmosphere helps dissipate the excess heat and maintains the cooling tower’s efficiency.

- Water Treatment and Maintenance: Cooling tower systems often incorporate water treatment methods to prevent scaling, corrosion, and the growth of microorganisms. Regular maintenance, including cleaning, inspection, and water quality monitoring, is essential to ensure optimal performance and prevent potential issues.

By utilizing evaporation and heat exchange, cooling towers effectively remove heat from industrial processes or air conditioning systems, enabling the equipment to operate within the desired temperature range. They play a vital role in maintaining efficient and safe operations while reducing energy consumption and enhancing overall productivity.

Cooling towers operate on the principle of evaporative cooling, harnessing the natural phenomenon of water evaporation to dissipate heat. The process typically involves the circulation of water through the tower and the exchange of heat with the surrounding air.

Here’s a breakdown of how a cooling tower works:

- Heat Transfer: Hot water from industrial processes or equipment is pumped into the cooling tower system. The hot water is distributed over a series of fill materials within the tower. These fill materials enhance the water’s exposure to the air, increasing the surface area available for heat exchange.

- Air Movement: Simultaneously, fans or blowers located within the cooling tower induce a flow of air, either in a counterflow or crossflow configuration. This air movement facilitates the removal of heat from the water.

- Evaporation: As the hot water cascades down through the fill materials, it comes into contact with the upflowing air. This contact promotes evaporation, as a portion of the water absorbs heat from the remaining water and transforms it into vapor.

- Cooling Effect: The evaporation process results in a cooling effect, reducing the temperature of the water. The cooled water collects at the bottom of the cooling tower.

- Recirculation: The cooled water is then pumped back to the industrial processes or equipment that require cooling. This recirculation ensures a continuous flow of cooled water, allowing the cooling tower to effectively manage heat removal.

Cooling towers vary in size and design, depending on the specific requirements of the industrial application. They can be found in power plants, manufacturing facilities, chemical plants, refineries, and other industrial settings where heat dissipation is crucial.

Water treatment is an integral part of cooling tower systems. It helps maintain water quality, inhibits the growth of microorganisms, and prevents scaling and corrosion that could negatively impact the cooling process. Regular maintenance, including cleaning and inspections, is necessary to ensure the efficient and safe operation of cooling towers.

Types of cooling tower

Cooling towers come in various types, each designed to suit specific industrial applications and cooling requirements. Here are some commonly used types of cooling towers:

- Crossflow Cooling Towers: Crossflow cooling towers are widely used in commercial and industrial settings. In this design, the air flows horizontally across the falling water. The water is distributed over the fill material, and as it descends, it comes into contact with the upward flow of air. Crossflow towers are known for their compact size and ease of maintenance.

- Counterflow Cooling Towers: Counterflow cooling towers are another prevalent type found in many industries. In this configuration, the air flows vertically upward while the water cascades downward over the fill material. The counterflow design allows for better heat transfer efficiency and typically results in a smaller footprint compared to crossflow towers.

- Natural Draft Cooling Towers: Natural draft cooling towers utilize the stack effect to create airflow. The design relies on the temperature difference between the outside air and the warmer air inside the tower to induce a natural updraft. These towers are typically large and often found in power plants or other applications with high heat loads.

- Mechanical Draft Cooling Towers: Mechanical draft cooling towers employ fans or blowers to force air through the tower. This type of cooling tower provides more control over airflow and is commonly used in industrial processes that require precise temperature regulation. Mechanical draft towers can be either induced draft (fans located at the top of the tower) or forced draft (fans located at the base or top of the tower).

- Hybrid Cooling Towers: Hybrid cooling towers combine the features of both evaporative and dry cooling systems. These towers incorporate heat exchangers to allow for additional cooling through a secondary process, such as air or water cooling, in addition to the evaporative cooling process. Hybrid cooling towers are often used in applications where water availability is limited or water conservation is a priority.

- Closed Circuit Cooling Towers: Closed circuit cooling towers operate in a closed-loop system, with the cooling tower water separated from the process water. The process water flows through a heat exchanger while the cooling tower water circulates through the tower, transferring heat to the ambient air. Closed circuit cooling towers are commonly used in applications where the process water must be kept separate from the cooling tower water due to contamination concerns or specific temperature requirements.

Components of the cooling tower

| Component | Description |

|---|---|

| Fill Material | Fill material provides a large surface area for water and air contact, facilitating heat transfer through evaporation. Common materials include PVC, wood, or metal grids. |

| Water Distribution System | This system ensures an even distribution of water over the fill material. It typically includes nozzles, distribution basins, and piping. |

| Drift Eliminators | Drift eliminators capture water droplets entrained in the exhaust air to minimize water loss. They help maintain efficient water usage and prevent environmental concerns. |

| Fans or Blowers | Fans or blowers create airflow through the tower, facilitating the exchange of heat between the water and the surrounding air. They can be located at the top or bottom of the tower, depending on the tower design. |

| Water Collection Basin | The water collection basin collects and collects the cooled water at the bottom of the tower for recirculation or discharge. It is designed to separate debris and sediment from the water. |

| Louvers | Louvers are found on the sides of the cooling tower and help control the air intake and exhaust, optimizing airflow and heat dissipation. They can be adjusted to regulate cooling tower performance. |

| Makeup Water Supply | The makeup water supply provides a source of fresh water to compensate for water losses due to evaporation, drift, and bleed. It helps maintain the desired water level and chemistry in the cooling tower. |

| Water Treatment System | A water treatment system is used to maintain water quality by controlling factors such as pH, hardness, corrosion inhibitors, and biocides. It helps prevent scaling, corrosion, and microbiological growth. |

| Control System | The control system monitors and regulates various parameters, such as water level, temperature, and flow rates. It ensures the efficient operation of the cooling tower and may include automated controls for optimal performance. |

| Access Doors and Ladders | Access doors and ladders provide entry points for maintenance personnel to inspect and access internal components of the cooling tower. They facilitate routine inspections, cleaning, and repairs. |

Cooling tower water treatment

Cooling tower water treatment is a crucial aspect of maintaining the performance and longevity of cooling towers. It involves the implementation of various processes and technologies to ensure the quality of the water used in the cooling tower system. The primary goals of cooling tower water treatment are to prevent scale formation, control corrosion, inhibit microbial growth, and maintain optimal water chemistry.

Here are the key components and methods commonly employed in cooling tower water treatment:

- Water Filtration: Filtration is the initial step in the treatment process, where suspended solids and debris are removed from the water. Filters such as sand filters, cartridge filters, or multimedia filters are used to capture particles and improve water clarity.

- Chemical Water Treatment: Chemical treatment involves the use of various chemicals to address specific water quality issues. These chemicals include:

- Biocides: Biocides are used to control microbial growth, such as bacteria, algae, and fungi. They help prevent the formation of biofilms and the proliferation of harmful microorganisms like Legionella.

- Scale Inhibitors: Scale inhibitors are added to prevent the formation of mineral scale deposits, which can impede heat transfer and reduce the efficiency of the fluid cooler. These inhibitors help control the precipitation of minerals such as calcium, magnesium, and silica.

- Corrosion Inhibitors: Corrosion inhibitors protect metal surfaces from corrosion caused by water chemistry. They form a protective layer on the metal surfaces, reducing the likelihood of corrosion and extending equipment lifespan.

- pH Adjusters: pH adjusters are used to control and maintain the desired pH level of the water. Maintaining proper pH helps prevent scaling and corrosion issues.

- Water Softening: Water softening is employed in areas with high levels of hardness caused by the presence of minerals like calcium and magnesium. Water softeners use ion exchange resins to remove these minerals, reducing the potential for scale formation.

- Bleed and Makeup Water Control: Continuous monitoring and control of the bleed and makeup water are important to maintain water quality. Bleed refers to the controlled discharge of a portion of the fluid cooler water to remove accumulated solids and maintain water chemistry. Makeup water is added to compensate for the water loss due to evaporation, drift, and bleed. Proper control of these processes ensures water quality remains within specified limits.

- Ongoing Monitoring and Maintenance: Regular monitoring of water quality parameters, such as pH, conductivity, total dissolved solids (TDS), and microbiological levels, is essential to detect any deviations from the desired range. Additionally, routine maintenance activities, including cleaning of basins, nozzles, and fill materials, are necessary to prevent the buildup of debris and maintain optimal performance.

By implementing effective fluid cooler water treatment practices, industrial facilities can minimize the risk of equipment damage, improve energy efficiency, and ensure the safety of personnel. Proper water treatment helps optimize heat transfer, reduce maintenance costs, and extend the lifespan of cooling fluid cooler systems, contributing to the overall efficiency and reliability of industrial processes.

Applications of the cooling tower

| Application | Description |

|---|---|

| Power Plants | Fluid coolers are widely used in power plants to dissipate heat generated by electricity generation processes. They help maintain optimal operating conditions for power generation equipment. |

| Industrial Processes | Cooling towers play a crucial role in various industrial processes, including manufacturing, chemical production, oil refining, and steel production. They help remove heat from equipment or processes, ensuring efficient operation and product quality. |

| HVAC Systems | Data centers generate significant heat due to the operation of computer servers. fluid coolers are used to remove heat from data center facilities, ensuring stable and efficient operation of the servers. |

| Data Centers | Data centers generate significant heat due to the operation of computer servers. fluid cooler are used to remove heat from data center facilities, ensuring stable and efficient operation of the servers. |

| Refineries | Refineries require cooling towrs to cool process fluids and equipment, such as heat exchangers, condensers, and reactors. Cooling towrs help maintain safe operating temperatures and optimize the refining process. |

| Chemical Plants | Cooling towrs are extensively used in chemical plants to remove heat generated during chemical reactions and manufacturing processes. They enable precise temperature control and prevent equipment damage. |

| Petrochemical Facilities | Petrochemical facilities utilize cooling towrs to cool fluids and gases involved in the production of various petrochemical products. Cooling towrs play a vital role in maintaining optimal operating conditions and enhancing process efficiency. |

| Food and Beverage Industry | Cooling towrs are used in the food and beverage industry for process cooling, refrigeration, and chilling applications. They help maintain the quality and safety of perishable products during production and storage. |

| Pharmaceutical Industry | Cooling towrs find application in the pharmaceutical industry for cooling equipment, process cooling, and maintaining stable conditions in cleanrooms. They are critical for pharmaceutical manufacturing processes. |

| Textile Industry | Cooling towrs are utilized in textile manufacturing processes to cool the dyeing and printing equipment, ensuring consistent product quality and preventing equipment overheating. |

| Plastics Industry | Cooling towrs are essential in the plastics industry for cooling extruders, injection molding machines, and other equipment involved in plastic processing. They help maintain precise temperature control and improve product quality. |

Frequently Asked Questions:

What is the purpose of fill material in a cooling tower?

Answer: The fill material provides a large surface area for water and air contact, facilitating efficient heat transfer through evaporation.

How does a crossflow cooling tower differ from a counterflow cooling tower?

Answer: In a crossflow fluid cooler, the air flows horizontally across the falling water, while in a counterflow fluid cooler, the air flows vertically upward as the water cascades downward.

What is the role of drift eliminators in a cooling tower?

Answer: Drift eliminators capture water droplets entrained in the exhaust air, reducing water loss and minimizing environmental concerns.

What is the purpose of fans or blowers in a cooling tower?

Answer: Fans or blowers create airflow through the fluid cooler, facilitating the exchange of heat between the water and the surrounding air, enhancing the cooling process.

How does water treatment in a cooling tower help prevent scaling and corrosion?

Answer: Water treatment involves the use of chemicals and processes to control water chemistry, preventing the formation of scale deposits and protecting metal surfaces from corrosion.

What is the function of a water distribution system in a cooling tower?

Answer: The water distribution system ensures an even distribution of water over the fill material, optimizing heat transfer efficiency and maintaining consistent cooling performance.

How does a closed circuit cooling tower differ from an open circuit cooling tower?

Answer: In a closed circuit fluid coolers, the fluid coolersr water is separate from the process water, preventing contamination. Open circuit cooling towers directly expose the process water to the fluid coolers.

What is the purpose of louvers in a cooling tower?

Answer: Louvers are adjustable panels on the sides of the cooling tower that control the intake and exhaust airflow, optimizing cooling efficiency and performance.

How does a natural draft cooling tower generate airflow?

Answer: Natural draft fluid coolers utilize the stack effect, where the temperature difference between the outside air and the warmer air inside the tower creates an upward draft, inducing airflow.

What are the main considerations when selecting a cooling tower for a specific application?

Answer: Factors to consider include cooling requirements, space availability, water availability, environmental regulations, energy efficiency, maintenance requirements, and budget constraints.

What is a cooling tower vs chiller?

Answer:

| Cooling Tower | Chiller |

|---|---|

| Device used to remove heat from water through evaporation | Refrigeration device that cools a liquid or air using a cycle |

| Primarily used for heat dissipation | Primarily used for air conditioning, process cooling, or refrigeration |

| Removes excess heat generated by industrial processes | Provides controlled cooling at specific temperatures |

| Relies on evaporation and convection | Relies on mechanical compression or absorption refrigeration cycle |

| Typically open systems | Closed-loop systems |

| Uses ambient air for cooling | Uses refrigerants for heat transfer |

| Requires a water source for operation | Requires electricity to power the compressor and other components |

| Larger structures and installations | Compact designs suitable for various applications |

What is the cooling tower process?

The cooling tower process is a mechanism used to remove excess heat from industrial processes or equipment by exchanging it with the surrounding air through the principles of evaporation and convection. The process begins with the circulation of warm water, known as hot water or process water, from the industrial system or equipment into the fluid coolers. Inside the tower, the hot water is distributed over fill material, which provides a large surface area for increased contact between the water and air.

As the hot water cascades down through the fill material, it comes into contact with ambient air. At the same time, fans or blowers create an upward flow of air through the tower. This airflow promotes heat transfer, and a portion of the water evaporates, absorbing heat from the remaining water and reducing its temperature.

The evaporated water, along with the exhaust air, is expelled from the fluid coolers. To minimize water loss, drift eliminators are often employed to capture water droplets entrained in the exhaust air. The cooled water collects in a basin at the bottom of the tower, known as the sump, where it is either recirculated back to the industrial process or discharged based on specific requirements.

Water treatment systems are commonly integrated into fluid coolers to maintain water quality and prevent scaling, corrosion, and microbial growth. Regular maintenance activities, such as cleaning and inspections, ensure the efficient operation of the fluid coolers.

Overall, the fluid cooler process efficiently dissipates heat through evaporation and convection, contributing to the optimal functioning and productivity of industrial processes while preventing equipment from overheating.

My cousin owns a factory for shoemaking, and it seems like he uses a cooling tower to keep the indoor temperature comfortable for the workers inside the factory. I appreciate your explanation when you informed us that it is the louvers that are adjusted to regulate cooling tower performance since they control the air intake and exhaust to optimize airflow and heat dissipation. I’ll keep this in mind while I look for a manufacturing company of cooling tower parts to contact about the components that need replacing to bring back our cooling tower’s peak functionality.