There are lots of difference between pu flooring and epoxy flooring, Industrial epoxy flooring is a popular choice for a wide range of industrial settings due to its durability, chemical resistance, and ability to withstand heavy use and harsh conditions. There are different types of industrial epoxy flooring systems available, each with its own unique characteristics. Here are some common types.

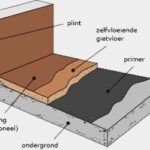

- Self-Leveling Epoxy Floors: Self-leveling epoxy is a popular choice for industrial applications. It creates a smooth, level surface by pouring the epoxy mixture onto the floor, allowing it to self-level and cure. This type of flooring provides a seamless, high-gloss finish and is easy to clean and maintain.

- Epoxy Mortar Floors: Epoxy mortar flooring is a heavy-duty option that consists of epoxy resin mixed with graded aggregates such as quartz or sand. The mixture forms a thick, trowel able mortar that is applied to the floor. Epoxy mortar floors are highly resistant to impact, abrasion, and chemicals, making them suitable for industrial environments with heavy traffic and potential exposure to harsh substances.

- Anti-Static or Conductive Epoxy Floors: In industries where static electricity poses a risk to sensitive equipment or materials, anti-static or conductive epoxy flooring is used. This type of flooring contains conductive materials that help dissipate static charges, preventing damage or accidents caused by electrostatic discharge.

- Chemical-Resistant Epoxy Floors: Industrial facilities often handle chemicals and substances that can be corrosive or damaging to conventional flooring materials. Chemical-resistant epoxy flooring is designed to withstand exposure to a wide range of chemicals, including acids, solvents, and oils. It provides a protective barrier that prevents the chemicals from seeping into the floor and causing damage.

- High-Build Epoxy Floors: High-build epoxy flooring systems are applied in multiple layers to create a thicker coating. These systems are highly durable, providing excellent resistance to abrasion, impact, and chemicals. High-build epoxy floors can be customized with various textures, patterns, or anti-slip additives to meet specific industrial requirements.

- Decorative Epoxy Floors: In addition to their functional benefits, epoxy floors can also be used to enhance the aesthetic appeal of industrial spaces. Decorative epoxy flooring systems offer a wide range of colors, patterns, and designs. They can be customized to create visually appealing surfaces while still maintaining the durability and performance of industrial-grade epoxy flooring.

These are some common types of industrial epoxy flooring. The choice of flooring system depends on factors such as the type of industry, the specific requirements of the facility, the expected level of foot and vehicle traffic, and the exposure to chemicals or other harsh conditions. Consulting with an epoxy flooring specialist can help determine the most suitable option for a particular industrial environment.

Difference between pu flooring and epoxy flooring

| Feature | PU Flooring | Epoxy Flooring |

|---|---|---|

| Material Composition | Made from polyurethane. | Made from epoxy resin and hardener. |

| Chemical Resistance | Good chemical resistance, but less resistant to harsh chemicals. | Excellent chemical resistance, highly resistant to harsh chemicals. |

| Durability | Highly durable, but less durable than epoxy. | Easier to install and requires fewer coats and less preparation. |

| Installation | Easier to install requires fewer coats and less preparation. | Highly durable, and can withstand heavy foot traffic and machinery. |

| Aesthetics | Limited color and pattern options. | Wide range of color and pattern options, often used for decorative purposes. |

| Cost | Generally less expensive than epoxy. | Generally more expensive than PU, but varies depending on the specific product and installation requirements. |

PU flooring Vs epoxy flooring.

| Aspect | PU Flooring | Epoxy Flooring |

|---|---|---|

| Durability | Highly durable | Highly durable |

| Chemical Resistance | Good resistance to chemicals and solvents | Excellent resistance to chemicals and solvents |

| Impact Resistance | Moderate impact resistance | High impact resistance |

| Abrasion Resistance | Moderate abrasion resistance | High abrasion resistance |

| UV Resistance | Moderate resistance to UV rays | Some epoxy systems may have UV-resistant properties |

| Installation | Can be more time-consuming and complex | Relatively faster and simpler installation process |

| Maintenance | Easy to clean and maintain | Easy to clean and maintain |

| Appearance | Usually provides a glossy and smooth finish | Can be glossy or matte, depending on the system used |

| Cost | Generally more expensive than epoxy flooring | Generally less expensive than PU flooring |

frequently Asked Questions

What is epoxy flooring made of?

Answer: Epoxy flooring is made of a combination of epoxy resin and hardener.

What is PU flooring made of?

Answer: PU flooring is made of polyurethane.

Which is more chemical resistant, epoxy flooring or PU flooring?

Answer: Epoxy flooring is generally more chemical resistant than PU flooring.

Which is more durable, epoxy flooring or PU flooring?

Answer: PU flooring is generally more durable than Epoxy flooring.

Which is easier to install, epoxy flooring or PU flooring?

Answer: PU flooring is generally easier to install than epoxy flooring.

Can epoxy flooring be used for decorative purposes?

Answer: Yes, epoxy flooring is often used for decorative purposes due to its wide range of color and pattern options.

Can PU flooring be used for decorative purposes?

Answer: PU flooring has limited color and pattern options and is generally not used for decorative purposes.

Is epoxy flooring more expensive than PU flooring?

Answer: Generally, epoxy flooring is more expensive than PU flooring.

Which type of flooring is better for areas with heavy machinery?

Answer: Epoxy flooring is better for areas with heavy machinery as it is more durable and can withstand heavy foot traffic.

Which type of flooring is better for areas with exposure to harsh chemicals?

Answer: Epoxy flooring is better for areas with exposure to harsh chemicals as it is highly chemical resistant.

Which type of flooring is better for healthcare facilities?

Answer: PU flooring is generally better for healthcare facilities as it offers good slip resistance, is easy to clean, and has a lower VOC content than epoxy flooring.

Can both epoxy and PU flooring be used for industrial and commercial applications?

Answer: Yes, both epoxy and PU flooring are commonly used in industrial and commercial applications.

Which type of flooring is better for areas with high foot traffic?

Answer: Epoxy flooring is better for areas with high foot traffic as it is highly durable and can withstand heavy use.

Can both epoxy and PU flooring be installed over existing concrete floors?

Answer: Yes, both epoxy and PU flooring can be installed over existing concrete floors.

Which type of flooring has better UV resistance?

Answer: PU flooring has better UV resistance than epoxy flooring.

Which type of flooring is better for areas with temperature fluctuations?

Answer: Both epoxy and PU flooring can handle temperature fluctuations, but epoxy flooring is generally more resistant to thermal shock.

Can both epoxy and PU flooring be customized to meet specific design needs?

Answer: Yes, both epoxy and PU flooring can be customized to meet specific design needs.

Which type of flooring requires more maintenance?

Answer: PU flooring requires more maintenance than epoxy flooring as it is more prone to scratches and scuffs.

Which type of flooring has better impact resistance?

Answer: Epoxy flooring has better impact resistance than PU flooring.

Which type of flooring is better for food and beverage facilities?

Answer: Both epoxy and PU flooring are suitable for food and beverage facilities, but epoxy flooring is more commonly used due to its excellent chemical resistance.

You may also read about Microbiology Guidelines