Hot water generators revolutionize pharmaceutical manufacturing processes. Explore efficient solutions tailored to meet the stringent demands of the pharmaceutical industry. Learn how these systems ensure precise temperature control and consistent performance, optimizing production efficiency. In the pursuit of efficiency, reliability, and sustainability, the world of hot water generation has seen remarkable advancements. Among these, the Hot Water Generator System stands out as a beacon of innovation, offering a compact and automatic solution to meet diverse heating needs.

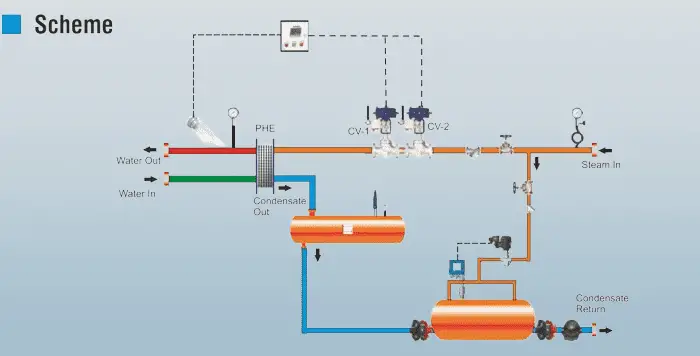

Designed to deliver hot water with precision and efficiency, the HWGS boasts a range of features that set it apart from conventional heating systems. From its pre-fabricated compact design to its plug-and-play functionality, this system streamlines the process of hot water production, eliminating the need for manual intervention and ensuring consistent temperature control.

Working Principle of the HOT Water Generator System:

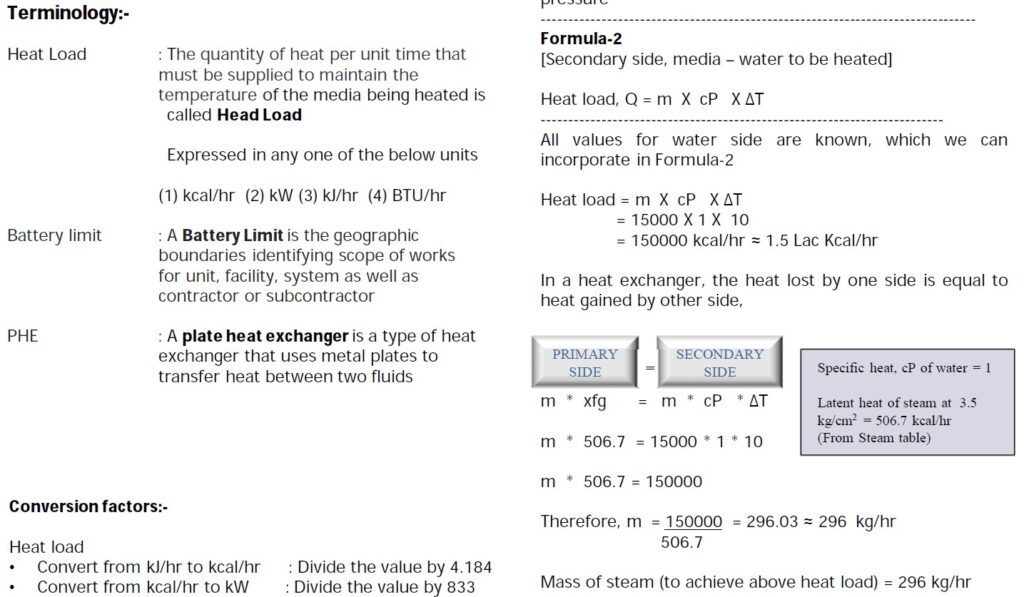

The working principle of a Hot Water Generator System in HVAC (Heating, Ventilation, and Air Conditioning) revolves around the efficient transfer of heat energy from a primary medium, typically low-pressure saturated steam, to a secondary medium, which is water. This process enables the generation of hot water for various heating applications within HVAC systems.

Here’s a breakdown of the working principle:

- Primary Medium Supply: The system begins with the supply of low-pressure saturated steam, which serves as the primary medium for transferring heat energy. This steam is typically supplied within recommended pressure and temperature ranges.

- Heat Transfer: The primary medium, i.e., the steam, enters the system and passes through a plate heat exchanger (PHE). The plate heat exchanger consists of multiple metal plates that facilitate the transfer of heat from the steam to the water.

- Counter Flow Heat Transfer: The heat transfer process in the plate heat exchanger occurs through a counterflow mechanism. This means that the steam and water flow in opposite directions, maximizing the efficiency of heat exchange.

- Secondary Medium Circulation: Simultaneously, the secondary medium, which is water, is circulated through the plate heat exchanger. As the steam transfers its heat energy to the water, the temperature of the water increases, resulting in the generation of hot water.

- Control and Regulation: The system is equipped with various control mechanisms to regulate the temperature and flow rates of both the steam and water. This ensures that the desired outlet temperature of the hot water is achieved and maintained consistently.

- Condensate Recovery: As the steam loses heat energy and condenses within the plate heat exchanger, the resulting condensate is recovered using an automatic pumping trap (APT). This ensures efficient utilization of the steam and prevents energy loss.

- Hot Water Distribution: Once the water has been heated to the desired temperature, it is ready for distribution to different parts of the HVAC system where it is required for space heating, domestic hot water supply, or other heating applications.

- Safety Measures: Safety valves and pressure safety mechanisms are integrated into the system to prevent overpressure conditions and ensure safe operation at all times.

In essence, the Hot Water Generator System in HVAC operates on the principle of efficient heat transfer from steam to water, facilitated by a plate heat exchanger, to generate hot water for various heating applications while ensuring energy efficiency and safety.

Hot water generator manufacturer :

In India, there are several manufacturers of hot water generators, catering to the diverse needs of industries, commercial establishments, and residential applications. Some prominent hot water generator manufacturers in India include:

- Thermax Limited: Thermax is a leading provider of energy and environment solutions, offering a wide range of heating equipment including hot water generators for various industries such as textiles, food processing, pharmaceuticals, and more.

- Forbes Marshall: Forbes Marshall specializes in steam engineering and control instrumentation solutions. They offer hot water generators designed for efficient and reliable operation, suitable for heating applications in industries, hospitals, hotels, and commercial buildings.

- Industrial Boilers Ltd (IBL): IBL is a pioneer in the design and manufacture of hot water generators and other heating equipment. Their hot water generators are used in diverse sectors such as hotels, hospitals, textiles, chemicals, and process industries.

- Energypack Boilers Pvt. Ltd.: Energypack Boilers is known for its high-quality boilers and heating systems, including hot water generators. Their products are widely used in industries like pharmaceuticals, chemicals, food processing, and hospitality.

- Balkrishna Boilers Pvt. Ltd.: Balkrishna Boilers manufactures a range of hot water generators that are efficient, reliable, and easy to operate. Their products find applications in industries such as textiles, chemicals, rubber, and hospitals.

- Saz Boilers: Saz Boilers offers hot water generators designed to provide a continuous supply of hot water for various industrial and commercial heating applications. Their products are known for their durability and energy efficiency.

- Ross Boilers: Ross Boilers manufactures hot water generators with advanced features to ensure optimum performance and energy savings. Their products are used in industries like pharmaceuticals, chemicals, textiles, and food processing.

- Shanti Boilers & Pressure Vessels Pvt. Ltd.: Shanti Boilers specializes in the design and manufacture of hot water generators, steam boilers, and thermal oil heaters. Their hot water generators are used in industries across India and overseas.

- Real Boilers Pvt. Ltd.: Real Boilers offers a range of hot water generators designed to meet the heating requirements of various industries. Their products are known for their efficiency, durability, and low maintenance.

- Microtech Boilers Pvt. Ltd.: Microtech Boilers manufactures hot water generators suitable for industrial and commercial heating applications. Their products are designed to deliver consistent performance and high efficiency.

- Uni Klinger: UNIKLINGER, in keeping with the Innovative Methods to help Process Industry achieve higher levels of operational efficiency have – UKL PACKAGE HOT WATER SYSTEM In Modular Designs-With the space availability at high premium, one needs a Quick, Efficient and Reliable source of Hot Water for process heating applications. And this is the hallmark of UKL HWG System as with all other UKL products and services

On a global scale, there are also several renowned manufacturers of hot water generators, including:

- Fulton Boiler Works, Inc. (USA)

- Clayton Industries (USA)

- Babcock Wanson (France)

- Viessmann Werke GmbH & Co. KG (Germany)

- Bosch Industriekessel GmbH – Industrial Boilers (Germany)

- Hurst Boiler & Welding Co., Inc. (USA)

- Alfa Laval AB (Sweden)

- Cannon Bono Energia (Italy)

- Cleaver-Brooks, Inc. (USA)

- Parker Boiler Co. (USA)

These manufacturers supply hot water generators to various industries worldwide, providing efficient and reliable solutions for heating needs.

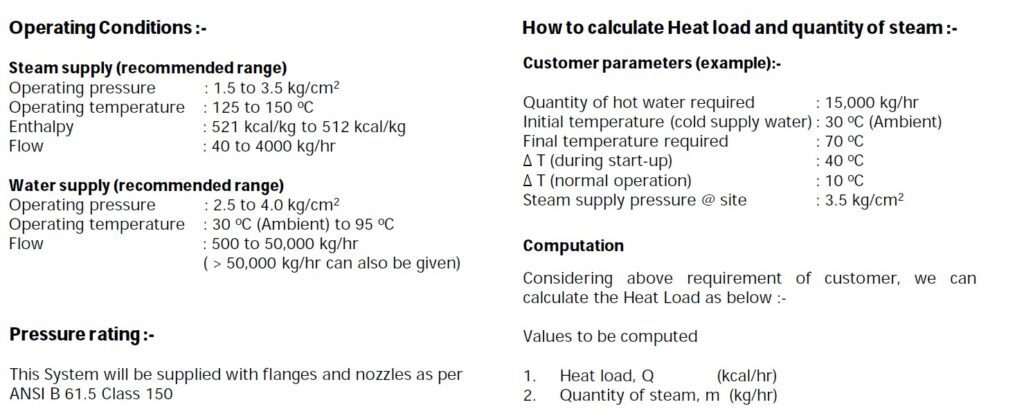

Technical specifications of the Hot Water Generator System:

| Specification | Details |

|---|---|

| Primary Medium | Low-pressure saturated steam |

| Secondary Medium | Water |

| Heat Exchanger Type | Plate heat exchanger (PHE) |

| Heat Transfer Mechanism | Counterflow |

| Control Mechanism | Automatic operation with temperature and flow rate regulation |

| Heat Load Capacity | 0.1 to 10.00 Lac Kcal/hr |

| Operating Pressure (Steam) | 1.5 to 3.5 kg/cm2 |

| Operating Temperature (Steam) | 125 to 150°C |

| Steam Enthalpy | 521 kcal/kg to 512 kcal/kg |

| Steam Flow Rate | 40 to 4000 kg/hr |

| Operating Pressure (Water) | 2.5 to 4.0 kg/cm2 |

| Operating Temperature (Water) | 30°C (Ambient) to 95°C |

| Water Flow Rate | 500 to 50,000 kg/hr |

| Pressure Rating | ANSI B 61.5 Class 150 flanges and nozzles |

| Safety Mechanisms | Safety valves, pressure safety mechanisms |

| Condensate Recovery | Automatic pumping trap (APT) for 100% condensate recovery |

| Salient Features | – Pre-assembled compact skid |

| – Zero loss of energy through automatic operation | |

| – Consistent temperature control (±1°C) | |

| – Efficient heat exchanger for optimal heat transfer | |

| – Baffle type moisture separator for enhanced steam quality | |

| – Quick response, light-weight, and modular design | |

| Weight | – Empty weight: 900 to 1500 kgs (dependent on models) |

| – Operating weight: 1100 to 1800 kgs (dependent on models) | |

| Applications | – Heating and cooling systems in various industries |

| – Space heating and domestic hot water supply | |

| – Sterilization, sanitization, and hot air generation | |

| – Process heating applications in pharmaceuticals, food, etc. |

These specifications provide a comprehensive overview of the Hot Water Generator System in HVAC, including its capabilities, operating parameters, safety features, and applications.

SOP for the Hot Water Generator

Calculations & formulas used while designing new HOT water generator system:

When designing a new Hot Water Generator System, several calculations and formulas are utilized to ensure optimal performance and efficiency. Here are some of the key calculations and formulas commonly used in the design process:

- Heat Load Calculation:

- Formula: Q=m×cp×ΔT

- Where:

- Q = Heat load (kcal/hr)

- m = Mass flow rate (kg/hr)

- cp = Specific heat capacity of water (kcal/kg°C)

- ΔT = Temperature difference (°C) between initial and final temperatures

- Quantity of Steam Calculation:

- Formula: Q=m×Xfg

- Where:

- Xfg = Latent heat of steam (kcal/kg) at corresponding supply pressure

- Enthalpy Calculation:

- Formula: H=h+2gv2+Z

- Where:

- H = Enthalpy (kcal/kg)

- ℎh = Specific enthalpy (kcal/kg)

- v = Velocity (m/s)

- g = Acceleration due to gravity (m/s²)

- Z = Elevation (m)

- Conversion Factors:

- Conversion from kJ/hr to kcal/hr: Divide the value by 4.184

- Conversion from kcal/hr to kW: Divide the value by 833

- Conversion from BTU/hr to kcal/hr: Divide the value by 3.966

- Pressure Drop Calculation:

- Formula: Pressure drop = D×2×gf×L×G2

- Where:

- f = Friction factor

- L = Length of pipe (m)

- G = Mass flow rate (kg/s)

- D = Diameter of pipe (m)

- g = Acceleration due to gravity (m/s²)

- Plate Heat Exchanger Sizing:

- Determination of plate area and number of plates based on heat load and flow rates.

- Moisture Separator Sizing:

- Sizing based on steam flow rate, ensuring effective separation of moisture from steam.

- Pumping System Design:

- Determination of pump head and flow rate requirements based on system parameters and hydraulic calculations.

- Safety Valve Sizing:

- Sizing of safety valves to ensure adequate relief capacity based on system pressure and flow conditions.

- Temperature Control System Design:

- Selection of appropriate temperature control valves and sensors for maintaining desired outlet temperature.

Frequently Asked Question:

What is the use of hot water generator in HVAC system?

Answer: Hot water generators are used in HVAC systems to provide a continuous supply of hot water for heating buildings, maintaining comfortable indoor temperatures, and powering various heating processes such as radiant heating, underfloor heating, and heat exchangers.

What is the difference between boiler and hot water generator?

Answer: A boiler is a closed vessel that heats water to generate steam, while a hot water generator is a system specifically designed to produce hot water directly for heating purposes without generating steam.

What is the full form of HWG in HVAC system?

Answer: HWG stands for Hot Water Generator in HVAC system.

What is the capacity of the hot water generator?

Answer: The capacity of a hot water generator can vary depending on its design and application, ranging from small units providing a few thousand kcal/hr to larger systems with capacities exceeding several lakh kcal/hr.

What is a hot water generator?

Answer: A hot water generator is a heating device that uses various energy sources to heat water and deliver it at a controlled temperature for domestic or industrial heating applications.

Does HVAC use hot water heater?

Answer: Yes, HVAC systems often utilize hot water heaters as a heat source to provide hot water for space heating, domestic hot water supply, and other heating requirements.

What is the full form of CFM in AHU?

Answer: CFM stands for Cubic Feet per Minute in Air Handling Unit.

What is VCD in HVAC?

Answer: VCD stands for Volume Control Damper, a device used in HVAC systems to regulate the airflow volume in ducts.

What is the full form of CFM in AHU capacity?

Answer: CFM in AHU capacity refers to the airflow capacity of an Air Handling Unit, measured in Cubic Feet per Minute.

How does a hot water system work?

Answer: A hot water system typically involves heating water using a heat source such as a boiler or hot water generator. The heated water is then circulated through pipes to heat exchangers, radiators, or other heating devices, providing warmth to spaces or facilitating industrial processes.

What is in a hot water system?

Answer: A hot water system consists of a heat source (boiler or hot water generator), circulation pumps, pipes, control valves, radiators or heat exchangers, expansion tanks, and temperature control devices.

How is hot water pumped?

Answer: Hot water is typically pumped through a closed-loop piping system using circulation pumps, which apply pressure to move the water from the heat source to the desired heating zones or applications.

Is a boiler a hot water system?

Answer: Yes, a boiler can be part of a hot water system as it is commonly used to heat water for both domestic and industrial heating purposes.

Is a boiler a generator?

Answer: A boiler is not technically a generator, as it primarily produces steam rather than electricity. However, it does generate heat energy in the form of steam or hot water.

What is difference between boiler and steam generator?

Answer: While both boilers and steam generators produce steam, boilers typically use water as a working fluid and transfer heat through combustion or electric heating elements, while steam generators often use specialized designs and may utilize different fluids or processes for steam generation.

How many watts is hot water?

Answer: The wattage of hot water depends on factors such as the volume of water, the temperature rise required, and the heating time. It can be calculated using formulas related to energy transfer and specific heat capacity.

How many Litres is a hot water system?

Answer: The capacity of a hot water system is typically measured in liters and varies depending on the size and design of the system. It can range from small residential units with a few liters of storage to large industrial systems with thousands of liters.

How do you calculate hot water boiler capacity?

Answer: Hot water boiler capacity is calculated based on factors such as the heat load requirements, temperature rise needed, and flow rates. Formulas involving heat transfer and specific heat capacity are used for this calculation.

What is the purpose of water generator?

Answer: The purpose of a water generator is to produce hot water efficiently for heating applications, providing a continuous and reliable supply of hot water for various residential, commercial, and industrial purposes.

How does a hot air generator work?

Answer: A hot air generator uses a heat source such as combustion or electrical heating elements to heat air, which is then circulated through ducts or spaces to provide warmth for heating applications, drying processes, or industrial operations.

What is the use of water generator?

Answer: Water generators are used to produce hot water for various heating applications in HVAC systems, including space heating, domestic hot water supply, industrial processes, and hydronic heating systems.

Do you need a boiler for hot water?

Yes, a boiler is often required in a hot water system to heat water and provide a continuous supply of hot water for heating purposes, especially in larger or industrial applications.

What is a combi boiler?

Answer: A combi boiler, short for combination boiler, is a type of boiler that provides both space heating and domestic hot water supply in a single compact unit, eliminating the need for a separate hot water storage tank.

What is the theory of steam generator?

Answer: The theory of a steam generator involves the conversion of water into steam through the application of heat energy, typically achieved by boiling water in a closed vessel called a boiler. The steam generated can then be used for various applications such as power generation, heating, or industrial processes.

I love reading a post that will make people think.

Also, thanks for allowing for me to comment!

Thank you for the good writeup. It actually

used to be a entertainment account it. Look complex to

far added agreeable from you! However, how can we be in contact?