Enhancing Efficiency and Precision: Exploring the Diversity of HVAC Dampers in Pharmaceutical Plants. In the intricate ecosystem of pharmaceutical plants, where precision, control, and hygiene are paramount, the role of HVAC systems is indispensable. Within these systems, dampers emerge as critical components, orchestrating the flow of conditioned air with exacting precision. Understanding the nuances of dampers in this specialized environment is essential for optimizing both operational efficiency and regulatory compliance.

The Essence of Dampers in HVAC Systems

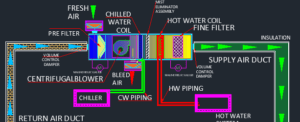

Dampers serve as gatekeepers within the ducted air conditioning systems prevalent in pharmaceutical plants. Acting as regulators of airflow, these components determine the volume of conditioned air directed into each space via ducts. Whether it’s cooling or heating, dampers play a pivotal role in maintaining the desired temperature and airflow within the facility.

In the context of pharmaceutical plants, where stringent environmental controls are imperative, the ability to fine-tune airflow becomes even more critical. Dampers not only facilitate temperature control but also contribute to maintaining optimal air quality and preventing cross-contamination—a fundamental requirement in pharmaceutical manufacturing environments.

Types of Dampers based air flow:

1. Volume Control Dampers (VCDs): Volume control dampers are perhaps the most common type of damper used in HVAC systems. They regulate the flow of air within ducts by adjusting the opening or closing of blades. In pharmaceutical plants, VCDs are often employed to balance airflow distribution, ensuring consistent air delivery to various areas where specific environmental conditions are required.

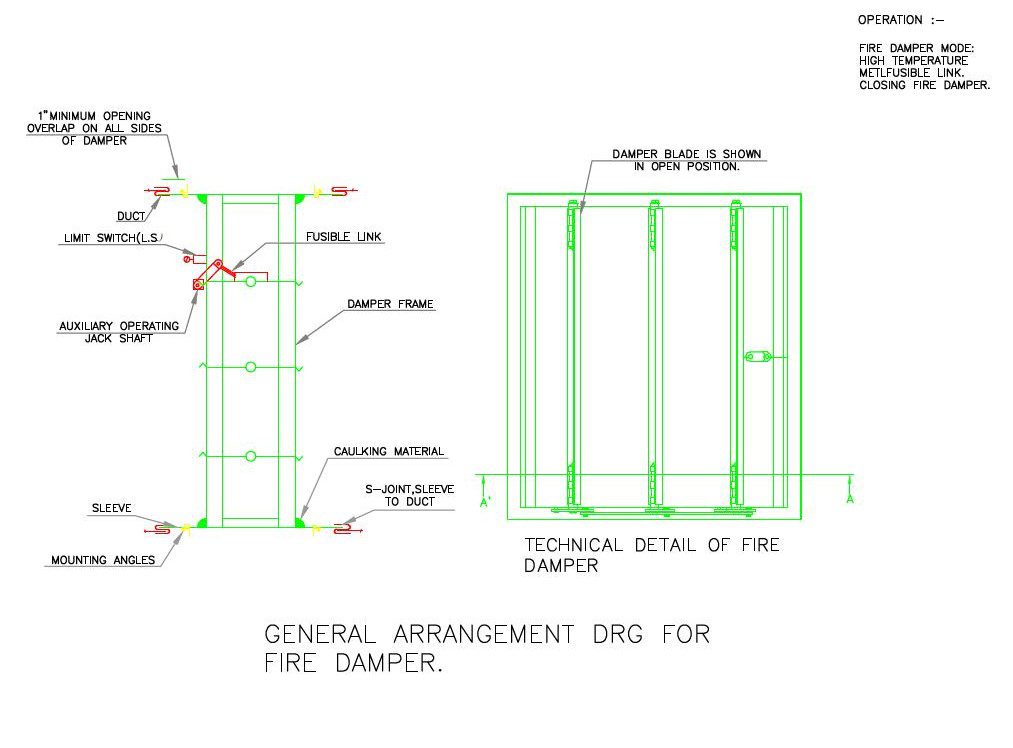

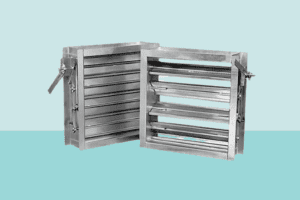

2. Fire Dampers: Fire dampers are critical safety devices designed to prevent the spread of fire and smoke through HVAC ductwork. They remain in an open position during normal operation but automatically close upon detecting high temperatures or the presence of smoke. In pharmaceutical plants, where stringent safety standards are paramount, fire dampers are essential for containing fire incidents and protecting personnel and valuable assets.

3. Smoke Dampers: Similar to fire dampers, smoke dampers are installed within HVAC ducts to prevent the spread of smoke in the event of a fire. However, smoke dampers may also be used independently of fire dampers to control smoke movement within a building during non-fire-related situations, such as smoke evacuation in case of equipment malfunction. In pharmaceutical plants, where maintaining a clean and controlled environment is imperative, smoke dampers help mitigate risks associated with smoke contamination.

4. Pressure Relief Dampers: Pressure relief dampers are employed to regulate air pressure within HVAC systems, particularly in areas where pressure differentials need to be controlled to avoid air leakage or ensure proper ventilation. In pharmaceutical plants, pressure relief dampers are used to maintain controlled environments in cleanrooms, laboratories, and production areas, where maintaining specific pressure differentials is crucial for preventing cross-contamination and ensuring product integrity.

5. Backdraft Dampers: Backdraft dampers, also known as backflow preventers or gravity dampers, are designed to allow airflow in one direction while preventing reverse airflow. They are commonly installed in HVAC exhaust systems to prevent outside air, contaminants, or odors from entering the building when the ventilation system is not in operation. In pharmaceutical plants, backdraft dampers are utilized in exhaust systems to maintain the integrity of cleanroom environments and prevent the ingress of external pollutants.

6. Motorized Dampers: Motorized dampers incorporate actuators or motors to automate the operation of dampers, allowing for remote control and adjustment of airflow. They offer enhanced precision and flexibility in regulating airflow and can be integrated into building automation systems for seamless operation. In pharmaceutical plants, motorized dampers are utilized in critical areas where precise environmental control is required, such as cleanrooms and research laboratories.

In pharmaceutical plants, where adherence to strict regulatory standards and maintaining optimal environmental conditions are paramount, selecting the appropriate types of dampers within HVAC systems is crucial. Each type serves a specific function in ensuring the integrity of controlled environments, safeguarding product quality, and protecting personnel and assets from potential hazards. By understanding the roles and applications of different damper types, pharmaceutical facilities can design HVAC systems that meet their unique operational requirements and regulatory compliance needs.

Types of various HVAC Dampers based on Operating Mode

- Butterfly Flat Dish Damper:

- Description: Butterfly dish dampers are engineered for high efficiency and minimal maintenance requirements. They feature a blade on a hinge mechanism, which, when aligned properly, obstructs the duct to regulate airflow.

- Functionality: These dampers can completely halt airflow and are available with multiple blades for specific applications.

- Applications: Ideal for use in Oxidizers, Baghouses, Scrubbers, Heaters, and Precipitators. They excel in preventing back-draft, making them suitable for fire prevention and heating applications.

- Advantages: High efficiency, low maintenance, excellent airflow control, and prevention of back-draft.

- Blade Dampers:

- Description: Blade dampers consist of thin metal plates designed to regulate airflow within air handling equipment, chimneys, and ducts. Opposed blade dampers feature blades that move in opposite directions.

- Functionality: They offer precise metering and control, with superior sealing capacity and reduced noise production.

- Applications: Widely used in HVAC systems for airflow regulation.

- Advantages: Greater strength, superior sealing capacity, precise control, and reduced noise.

- Guillotine Dampers:

- Description: Guillotine dampers are renowned for their ability to provide exceptional sealing. They are utilized to completely block airflow and are suitable for applications requiring isolation for maintenance or entry to ducts behind media sources.

- Functionality: Provides a tight seal to block airflow completely.

- Applications: Suitable for locations where proper isolation is necessary, such as maintenance access points.

- Advantages: Excellent sealing, ideal for maintenance access points.

- Louver Dampers:

- Description: Louver dampers are valued for their rapid response time and strong airflow blocking capabilities. They typically feature flat blades on hinges to fit various duct sizes.

- Functionality: Offers quick response time and effective airflow blocking.

- Applications: Widely used in HVAC systems for airflow regulation.

- Advantages: Quick response time, strong airflow blocking, versatility in fitting different duct sizes.

- Inlet Vane Dampers:

- Description: Inlet vane dampers are commonly employed in fan inlet applications to improve material flow and pressure control. They feature multiple blades arranged around a central hub, enhancing fan performance by introducing swirl into the inlet.

- Functionality: Enhances fan performance by introducing swirl into the inlet, providing effective control over airflow and pressure.

- Applications: Commonly used in HVAC settings where precise ventilation control is required.

- Advantages: Improved fan performance, precise airflow and pressure control.

Technical Specification of Damper, Consideration of the details while buying new Dampers:

| Detail | Description |

|---|---|

| Damper Type | Identify the specific type of damper required for the intended application (e.g., butterfly, blade, guillotine, louver, inlet vane). |

| Construction Material | Determine the material used in the construction of the damper (e.g., steel, aluminum, stainless steel) based on durability, corrosion resistance, and compatibility with the operating environment. |

| Operation | Decide whether manual, mechanical, or automatic operation is preferred, considering factors such as ease of use, control precision, and automation capabilities. |

| Blade Configuration | Evaluate the blade configuration (e.g., single, multiple, opposed blades) for optimal airflow control and efficiency. |

| Sealing Capacity | Assess the sealing capacity of the damper to ensure effective blocking of airflow when closed, particularly for applications requiring complete isolation or containment. |

| Noise Level | Consider the noise level produced by the damper during operation, aiming for minimal noise generation to maintain a comfortable indoor environment. |

| Maximum Airflow Capacity | Determine the maximum airflow capacity of the damper to ensure compatibility with the HVAC system’s airflow requirements and prevent airflow restrictions. |

| Maximum Operating Temperature | Verify the maximum operating temperature of the damper to ensure it can withstand the temperature extremes experienced in the HVAC system. |

| Size and Dimensions | Specify the size and dimensions of the damper to ensure proper fit and compatibility with the existing ductwork or equipment. |

| Control Mechanism | Select the appropriate control mechanism (e.g., manual lever, pneumatic actuator, electric motor) based on operational requirements and integration with existing HVAC controls. |

| Application | Consider the specific application or use case for the damper (e.g., HVAC systems, industrial processes, cleanrooms) to ensure it meets the functional and performance requirements of the intended environment. |

| Regulatory Compliance | Ensure that the damper complies with relevant industry standards, codes, and regulations (e.g., ASHRAE, NFPA) to maintain safety, performance, and regulatory compliance. |

These details provide a comprehensive checklist to guide the selection process when purchasing a new damper, ensuring that the chosen damper meets the functional, performance, and regulatory requirements of the intended application.

Frequently Asked Question:

What is the function of a damper?

Answer: The function of a damper is to regulate or control the flow of air within a duct or HVAC system. It can open or close to varying degrees to adjust airflow, thereby controlling temperature, pressure, and ventilation in different areas or zones of a building.

Why is a damper used in AHU?

Answer: A damper is used in an Air Handling Unit (AHU) to control the flow of air within the ductwork. It helps in adjusting airflow rates, balancing air distribution, and maintaining desired conditions in different zones or rooms of a building served by the AHU.

What are the three types of dampers?

Answer: The three main types of dampers commonly used in HVAC systems are Volume Control Dampers (VCDs), Fire Dampers, and Smoke Dampers.

How many dampers are on an HVAC?

Answer: The number of dampers in an HVAC system can vary depending on the system’s complexity, size, and design requirements. It may have multiple dampers installed throughout the ductwork to control airflow to different zones or areas.

What is called a damper?

Answer: A damper is a mechanical device used in HVAC systems to regulate airflow by opening or closing to control temperature, pressure, and ventilation within ducts or specific areas of a building.

What is a fire damper in HVAC?

Answer: A fire damper is a specialized type of damper installed within HVAC ductwork to prevent the spread of fire and smoke between different areas or compartments of a building. It automatically closes when exposed to high temperatures, helping to contain fire and protect occupants.

Where is the HVAC damper?

Answer: HVAC dampers are typically installed within ductwork, either close to the air handling unit or at various points along the ducts to control airflow to different areas or zones of a building.

Is an HVAC damper open or closed?

Answer: The position of an HVAC damper (open or closed) depends on the system’s operational requirements. Dampers can be adjusted to open or close partially or completely to regulate airflow as needed.

Do all HVAC have dampers?

Answer: Not all HVAC systems have dampers, but they are commonly used in systems designed for zoning, air balancing, or specific airflow control requirements. The presence of dampers depends on the system’s design and functionality.

What is a VCD in an HVAC system?

Answer: VCD stands for Volume Control Damper. It is a type of damper used in HVAC systems to adjust or control the volume of airflow within ductwork, thereby regulating temperature and ventilation in different areas of a building.

Is a damper a fan?

Answer: No, a damper is not a fan. A damper is a mechanical device used to regulate airflow within ducts or HVAC systems by opening or closing to control airflow, while a fan is a separate component used to circulate air within the system.

What controls a damper?

Answer: Dampers can be controlled manually using levers or knobs, mechanically using pneumatic or electric actuators, or automatically through HVAC control systems that respond to temperature, pressure, or other input signals.

What is a damper in a chiller?

Answer: In a chiller system, a damper may be used to control the flow of chilled water or air to different parts of the system, such as the evaporator or condenser, to regulate temperature and maintain optimal performance.

What is VFD for an ID fan?

Answer: VFD stands for Variable Frequency Drive. In the context of an ID (Induced Draft) fan, a VFD controls the fan’s speed by varying the frequency of the electrical power supplied to the motor. This allows for precise control of airflow and energy savings.

What is a VFD for fan speed?

Answer: A VFD (Variable Frequency Drive) for fan speed is a control device used to adjust the speed of a fan motor by varying the frequency of the electrical power supplied to the motor. It enables precise control of airflow and energy efficiency.

How are HVAC dampers controlled?

Answer: HVAC dampers can be controlled manually through levers or knobs, mechanically using pneumatic or electric actuators, or automatically through HVAC control systems that respond to temperature, pressure, or other input signals.

What is a duct system?

Answer: A duct system is a network of metal or flexible tubes used to distribute air from HVAC equipment to different areas or zones of a building. It facilitates the transport of heated or cooled air for ventilation, heating, or air conditioning purposes.

What is an attenuator in HVAC?

Answer: An attenuator in HVAC refers to a device used to reduce noise levels generated by airflow within ductwork. It typically consists of sound-absorbing materials or structures designed to dampen or attenuate sound waves, improving indoor comfort.

What is AHU in air conditioning?

Answer: AHU stands for Air Handling Unit. It is a component of HVAC systems responsible for conditioning and circulating air within a building. AHUs typically include fans, filters, heating or cooling coils, dampers, and controls to regulate airflow and temperature.

What is a damper valve?

Answer: A damper valve is another term for a damper, which is a mechanical device used in HVAC systems to regulate airflow within ducts or specific areas of a building by opening or closing to control temperature, pressure, and ventilation.

Are dampers bad for HVAC?

Answer: Dampers are not inherently bad for HVAC systems; in fact, they are essential components for regulating airflow and optimizing system performance. Properly designed and installed dampers can improve energy efficiency, comfort, and air quality in buildings. However, inadequate installation or maintenance of dampers may lead to airflow restrictions, inefficiencies, or issues with system operation.

1 thought on “Fire Damper in HVAC”