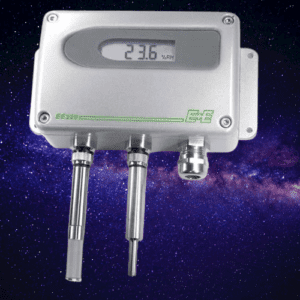

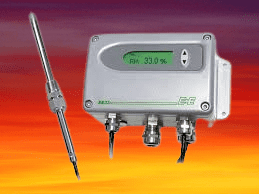

Humidity sensors, also known as hygrometers, are electronic devices designed to measure and monitor the level of humidity in the atmosphere. They employ advanced technologies to detect changes in water vapor concentration, allowing for precise humidity measurements. These sensors are capable of providing real-time data, facilitating informed decision-making and ensuring optimal environmental conditions in various settings.

What is humidity sensor

A humidity sensor, also known as a hygrometer, is an electronic device designed to measure and monitor the moisture content in the air or other gases. It provides valuable information about the humidity levels in a given environment, allowing for accurate and real-time monitoring of moisture conditions. Humidity sensors are widely used in various industries and applications where controlling and maintaining the right humidity levels is crucial for optimal performance, comfort, and safety.

These sensors work based on different principles, depending on the specific technology employed. One common type is the capacitive humidity sensor, which measures changes in the dielectric properties of a moisture-absorbing material. When the humidity increases, the material absorbs moisture, leading to a change in capacitance that can be measured and converted into a humidity reading.

Another type is the resistive humidity sensor, which utilizes a moisture-sensitive material that undergoes changes in electrical resistance as it absorbs or desorbs moisture. By measuring the resistance, the sensor can determine the humidity level in the surrounding environment.

There are also other sensing techniques employed in humidity sensors, such as thermal conductivity, where the sensor measures the heat transfer between a heated element and the surrounding air, or optical sensing, which relies on the absorption or reflection of light by moisture in the air. Each method has its advantages and suitability for specific applications.

Humidity sensors find widespread use in numerous industries. In HVAC systems, they help regulate indoor humidity for enhanced comfort and energy efficiency. They are essential in agriculture and horticulture, enabling precise control of moisture levels for optimal plant growth and irrigation management. In industrial processes, humidity sensors play a critical role in ensuring product quality, preventing corrosion, and maintaining stable conditions. They are also utilized in weather forecasting, environmental monitoring, museums, and archives to protect valuable artifacts and documents from moisture-related damage.

The data provided by humidity sensors allows for proactive decision-making, efficient resource management, and the creation of comfortable and safe environments. With advancements in technology, humidity sensors continue to improve, offering greater accuracy, reliability, and integration with other systems. As a result, they play a vital role in diverse fields, contributing to the advancement of numerous industries and the well-being of individuals worldwide.

Humidity sensor working principle

The working principle of a humidity sensor depends on the specific technology employed, as different types of humidity sensors utilize different mechanisms to measure moisture content. Here, we will explore the working principles of two commonly used humidity sensing technologies: capacitive and resistive.

- Capacitive Humidity Sensors: Capacitive humidity sensors operate based on the principle that the moisture in the air affects the dielectric properties of certain materials. These sensors consist of a humidity-sensitive material placed between two conductive electrodes. When the surrounding air contains moisture, the humidity-sensitive material absorbs or desorbs the water vapor, leading to a change in its dielectric constant.

As the dielectric constant of the material changes, the capacitance between the two electrodes also varies. The capacitance is inversely proportional to the distance between the electrodes, which is influenced by the moisture content. By measuring the capacitance, the humidity sensor can determine the relative humidity of the surrounding environment. This information is then converted into a humidity reading using calibration and signal conditioning circuitry.

- Resistive Humidity Sensors: Resistive humidity sensors operate based on the principle that certain materials exhibit changes in electrical resistance when exposed to moisture. These sensors typically use a moisture-absorbing or moisture-sensitive material such as polymers or ceramics with conductive properties.

The moisture-sensitive material is integrated into a resistive element or a resistor. When the material absorbs moisture, it undergoes a physical and chemical transformation, causing changes in its electrical conductivity or resistivity. As a result, the resistance of the sensor element changes in response to the moisture content in the surrounding environment.

By measuring the electrical resistance across the sensor element, the humidity sensor can determine the humidity level. This resistance value is then calibrated and converted into a humidity reading using appropriate circuitry and algorithms.

It’s worth noting that humidity sensors often require additional circuitry for temperature compensation, as temperature can influence the accuracy of humidity measurements. This compensation ensures that the sensor provides accurate and reliable readings by accounting for temperature variations.

In summary, capacitive humidity sensors rely on changes in capacitance caused by variations in the dielectric constant of a moisture-absorbing material, while resistive humidity sensors measure changes in electrical resistance resulting from the absorption or desorption of moisture by a moisture-sensitive material. These working principles allow humidity sensors to provide valuable information about moisture content in the air, enabling precise and real-time humidity measurements for a wide range of applications.

Application of humidity sensor

| Application | Description |

|---|---|

| HVAC Systems | Regulating humidity levels in heating, ventilation, and air conditioning systems to optimize comfort and energy efficiency. |

| Agriculture and Horticulture | Monitoring and controlling humidity in greenhouses, nurseries, and farms for precise irrigation and optimal plant growth. |

| Industrial Processes | Maintaining specific humidity levels in industrial settings to ensure product quality, prevent corrosion, and optimize manufacturing processes. |

| Museums and Archives | Preserving artifacts, historical documents, and artworks by controlling humidity levels to prevent deterioration and mold growth. |

| Weather Forecasting | Gathering data on humidity for accurate weather forecasting, climate research, and understanding atmospheric conditions. |

| Pharmaceuticals and Laboratories | Creating controlled environments with specific humidity levels to ensure product stability, quality control, and research accuracy. |

| Food and Beverage Industry | Monitoring and controlling humidity in food storage facilities and production environments to prevent spoilage and maintain freshness. |

| Data Centers | Managing humidity to protect sensitive electronic equipment from moisture-related damage and ensure efficient operation. |

| Automotive Industry | Monitoring and controlling humidity inside vehicles for improved comfort and to prevent fogging on windows. |

| Indoor Air Quality | Assessing and maintaining optimal humidity levels in residential and commercial buildings for occupant comfort and health. |

Types of humidity sensor

There are several types of humidity sensors available, each utilizing different technologies to measure and detect humidity levels. Here are some common types of humidity sensors:

- Capacitive Humidity Sensors: Capacitive RH sensors are widely used due to their accuracy and reliability. These sensors work based on the principle that the moisture content in the air affects the dielectric properties of certain materials. Changes in humidity cause the moisture-absorbing material to change its dielectric constant, which is then measured as a change in capacitance. Capacitive humidity sensors offer fast response times and are suitable for a wide range of applications.

- Resistive Humidity Sensors: Resistive RH sensors utilize a moisture-sensitive material that undergoes changes in electrical resistance when exposed to moisture. The resistance of the sensor element varies based on the moisture content in the surrounding environment. Resistive humidity sensors are cost-effective and suitable for many applications. However, they may be more sensitive to temperature variations and require additional calibration for accurate readings.

- Thermal Conductivity Humidity Sensors: Thermal conductivity humidity sensors measure the change in heat transfer caused by the presence of water vapor in the air. These sensors consist of a heated element and a temperature sensor. As moisture condenses on the sensor surface, it causes a change in thermal conductivity, resulting in a corresponding change in temperature. By measuring this temperature change, the humidity level can be determined. Thermal conductivity RH sensors are durable and can operate in harsh environments.

- Dew Point Sensors: Dew point sensors measure the dew point temperature, which is the temperature at which air becomes saturated and condensation begins to form. These sensors use various techniques such as chilled mirror, polymer, or capacitive methods to detect the dew point. Dew point sensors are commonly used in applications where preventing condensation is critical, such as in industrial processes or refrigeration systems.

- Gravimetric Humidity Sensors: Gravimetric RH sensors measure humidity by directly measuring the mass change of a moisture-absorbing material. The sensor absorbs or desorbs moisture from the air, and the change in mass is used to determine the humidity level. Gravimetric RH sensors offer high accuracy but may have slower response times and require more complex calibration procedures.

- Optical Humidity Sensors: Optical RH sensors utilize optical properties to measure humidity levels. These sensors measure the absorption or reflection of light by moisture in the air and use that information to determine humidity. Optical RH sensors can provide accurate readings, but they may be sensitive to contaminants or particulate matter in the air.

It’s important to note that each type of humidity sensor has its advantages and limitations. The selection of the appropriate sensor depends on the specific application requirements, including accuracy, response time, cost, environmental conditions, and calibration considerations.

wifi humidity sensor

A WiFi humidity sensor is a type of humidity sensor that is equipped with WiFi connectivity, allowing it to connect to a wireless network and communicate with other devices or systems over the internet. This feature enables remote monitoring and control of humidity levels, providing convenience and flexibility in various applications.

The WiFi capability of these sensors allows them to transmit humidity data in real-time to a designated server or cloud-based platform. From there, users can access the data using computers, smartphones, or other internet-connected devices, enabling remote monitoring and analysis of humidity conditions from anywhere with an internet connection.

The advantages of WiFi humidity sensors include:

- Remote Monitoring: WiFi RH sensors eliminate the need for physical presence near the sensor to collect data. Users can access the sensor’s readings remotely through a web-based interface or dedicated mobile applications, ensuring convenient monitoring from any location.

- Data Logging and Analysis: WiFi RHsensors often have built-in data logging capabilities, allowing them to record and store humidity readings over time. This data can be analyzed and used for trend analysis, historical comparisons, or generating reports to gain insights into environmental conditions.

- Alerts and Notifications: WiFi RH sensors can be configured to send notifications or alerts via email, SMS, or mobile app notifications when humidity levels exceed predetermined thresholds. This feature enables proactive response and intervention in case of abnormal or undesirable humidity conditions.

- Integration with Smart Home Systems: WiFi RH sensors can be integrated into smart home automation systems, allowing users to automate actions based on humidity levels. For example, the sensor can trigger a connected humidifier or dehumidifier to maintain optimal humidity levels automatically.

- Scalability and Expandability: WiFi RH sensors can be part of a larger network of connected devices, allowing for the expansion and integration of multiple sensors and other smart devices. This scalability enables comprehensive environmental monitoring and control in various settings.

Applications of WiFi humidity sensors can be found in residential, commercial, and industrial environments. They are commonly used in:

- Smart homes and buildings: WiFi RH sensors play a role in maintaining optimal indoor air quality, preventing mold growth, and ensuring comfort for occupants.

- Laboratories and research facilities: These sensors provide remote monitoring of humidity levels in controlled environments to maintain experiment integrity and equipment performance.

- Food storage and production facilities: WiFi RH sensors aid in monitoring humidity levels to prevent spoilage, maintain product quality, and comply with regulatory requirements.

- Museums and archives: WiFi RH sensors help preserve delicate artifacts, documents, and artworks by ensuring consistent humidity levels and raising alarms in case of deviations.

- HVAC systems: WiFi RH sensors can be integrated into HVAC systems to monitor and regulate humidity levels, improving energy efficiency and occupant comfort.

Overall, WiFi RH sensors offer the convenience of remote monitoring, data analysis, and integration with other smart devices, making them valuable tools for managing and maintaining optimal humidity conditions in various applications.

Frequently Asked Questions:

What is a humidity sensor?

Answer: A humidity sensor is an electronic device designed to measure and monitor the moisture content in the air or other gases.

How does a humidity sensor work?

Answer: Humidity sensors work based on different principles, such as capacitance, resistance, thermal conductivity, or optical sensing. These principles involve measuring changes in electrical properties, heat transfer, or light absorption to determine humidity levels.

What are the applications of humidity sensors?

Answer: Humidity sensors are used in HVAC systems, agriculture, industrial processes, museums, weather forecasting, data centers, and more, to control and monitor humidity for optimal performance, comfort, and safety.

How accurate are humidity sensors?

Answer: RH sensors can vary in accuracy depending on the specific technology and quality of the sensor. High-quality sensors can provide accuracies within a few percentage points.

Can humidity sensors measure other environmental factors?

Answer: Some RH sensors are integrated with additional sensors to measure temperature, pressure, or other environmental parameters. This integration allows for comprehensive environmental monitoring.

Do humidity sensors require calibration?

Answer: RH sensors typically require periodic calibration to ensure accurate readings. Calibration compensates for drift or changes in sensor performance over time.

Can humidity sensors be used outdoors?

Answer: Yes, RH can be used outdoors. However, it is important to select sensors designed for outdoor use and consider protection from environmental factors such as moisture, dust, and temperature extremes.

Can humidity sensors be connected to a network?

Answer: Yes, RH sensors can be equipped with connectivity options such as WiFi or wired connections, allowing for remote monitoring and integration with other systems.

How often should humidity sensors be replaced?

Answer: The lifespan of RH sensors can vary depending on factors such as sensor type, operating conditions, and quality. Generally, they can last several years, but periodic replacement or recalibration may be necessary.

Can humidity sensors detect condensation or dew formation?

Answer: Dew point sensors, specifically designed for this purpose, can detect condensation or dew formation by measuring the temperature at which moisture begins to condense. This information helps prevent condensation-related issues in various applications.