The purpose of this (Standard Operating Procedure) SOP For Preventive Maintenance of Incubators and Stability Chambers is the guidelines and procedures. Regular maintenance ensures the optimal performance, reliability, and accuracy of these critical equipment, thus ensuring the integrity of samples and stability studies.

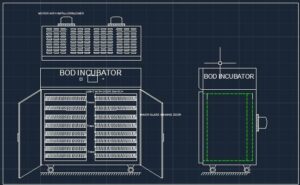

SOP for Preventive Maintenance of Incubators and Stability Chambers

OBJECTIVE:

- To lay down the procedure for Preventive Maintenance of Incubators and Stability Chambers.

SCOPE:

- This SOP is applicable to all Incubators and Stability Chambers.

RESPONSIBILITY:

- Engineering – The head or designee shall be responsible for reviewing the SOP and for ensuring proper execution of Preventive Maintenance of Incubators and Stability Chambers

- User Department – The head shall be responsible for ensuring that the preventive maintenance of equipment is done as scheduled.

- ACCOUNTABILITY:

- Engineering – The head shall be accountable for the proper implementation of the SOP for Preventive Maintenance of Incubators and Stability Chambers.

- DEFINITIONS:

- Nil

- PROCEDURE:

- Preventive maintenance shall be executed as per SOP No.: SOP/EN/XXXYYY – Execution of Preventive Maintenance.

- Precautions:

- Ensure that the equipment power supply has been disconnected.

- Check that the equipment is in empty condition and that any load has been shifted to equipment with the same condition.

- Frequency:

- 3 months ± 7 days

- Check Points in Preventive Maintenance of Incubators and Stability Chambers

- The following checkpoints should be ensured during preventive maintenance of Incubators & Stability chambers:

- Clean the chamber externally.

- Check for door leakages and clean the gaskets.

- Check the water level in the boiler and the condition of the gasket.

- Check inside the control panel and the machinery compartment for loose electrical connections, frayed wires, loose components, or other potential problems.

- Check refrigerant compressor low and high pressure.

- Check the working condition of the safety thermostat cut-off.

- Check the electric heater (s) inside the chamber conditioning plenum for any defects.

- Observe and clean the chamber circulation fan and the condenser with blower, if found loose, tighten it.

- Check and clean the drain pipe of chamber.

- Clean the humidifier tank (if available).

- Check the set points.

- Check that the alarm hooter is working properly.

- Check that the PLC battery is in proper condition.

- Check that the electrical panel cooling fan is working properly.

- Clean the sensor tip with the help of a smooth polish paper.

- Record the preventive maintenance details as per Format no. SOP/EN/XXXYYY

- Connect the equipment main power supply and start the equipment.

- Ensure that the equipment is running smoothly, without any abnormality.

- If any abnormality is observed in the above, same will be attended in co-ordination with User department Head.

- ABBREVIATIONS

- CRF No. : Change Request Form number

- QA : Quality Assurance

- PM : Preventive Maintenance

- REFERENCES

- Operational & Maintenance Manual of Incubators & Stability Chambers

- Execution of Preventive Maintenance: SOP/EN/XXXYYY

- DISTRIBUTION LIST

- SOP shall be distributed to the following departments Quality Assurance, Engineering as per user request.

- ANNEXURES

- Preventive Maintenance Checklist & Record for Incubators: SOP/EN/XXXYYY and Stability Chamber.

Checklist and Records in Preventive Maintenance of Incubators and Stability Chambers

| Things to be done: | Check List | Remarks |

| Clean the chamber externally. | ||

| Check for the door leakages and clean the door gaskets. | ||

| Check inside the control panel and the machinery compartment for loose electrical connections, frayed wires, loose components, or other potential problem. | ||

| Check refrigerant compressor low and high pressure. | ||

| Check the working condition of safety thermostat cut off. | ||

| Check the electric heater (s) inside the chamber conditioning plenum for any defects. | ||

| Observe and clean the chamber circulation fan and the condenser with blower, if found loose, tighten it. | ||

| Check and clean the drain pipe of the chamber. | ||

| Clean the humidifier tank (if available) | ||

| Check the set points. | ||

| Check that the alarm hooter is working properly. | ||

| Check that the PLC battery is in proper condition. | ||

| Check that the electrical panel cooling fan is working properly. | ||

| Clean the sensor tip with the help of a smooth polish paper. |

Mention √ or NA, whichever is applicable, under check list.

| Date of Scheduled PM | Actual PM done on | Next Due date | Done by | Checked by | Remarks |

PM – Preventive Maintenance