This SOP for Chemical Preparation in Water System outlines the procedures to be followed when preparing and introducing chemicals into the water system, ensuring the safety of personnel, equipment, and the environment while maintaining the quality of the water.

SOP for Chemical Preparation in Water System

- OBJECTIVE:

- To lay down the procedure for the chemical preparation in water system.

- SCOPE:

- This procedure is applicable for the chemical preparation procedure and maintaining the preparation record in water system.

- RESPONSIBILITY:

- Technician/ Operator/ Engineer shall be responsible for proper execution of operation as per SOP for Chemical Preparation in Water System.

- Engineering – Head shall be responsible for reviewing the SOP and ensuring proper execution and its compliance.

- ACCOUNTABILITY:

- Head of department – Engineering & Maintenance shall be accountable for the SOP for Chemical Preparation in Water System.

- DEFINITIONS:

- Chemical preparation in a water system refers to the deliberate and controlled process of selecting, measuring, mixing, and introducing specific chemicals into a water supply or treatment system. These chemicals are chosen based on their intended effects, such as disinfection, pH adjustment, coagulation, or removal of contaminants

PROCEDURE for Chemical Preparation in Water System

- The following Chemical will utilize in water system.

Preparation of Sodium Hypochlorite solution

- Fill the dosing tank with Purified water.

- Make 4% sodium hypochlorite solution in tank as per chemical formula is mentioned at point 6.5

- Solution of sodium hypochlorite can be prepared in low quantity depending on consumption.

- Stir the solution with SS rod till dissolves.

- Enter the preparation detail in Format no. SOP/EN/XXXYYY.

- Start dosing the solution as per requirement.

Preparation of sodium hydroxide solution:

- Fill the dosing tank with Purified water.

- Make 3% sodium hydroxide solution in tank as per chemical formula is mentioned at point 6.5.

- Solution of sodium hydroxide can be prepared in low quantity depending on consumption.

- Stir the solution with SS rod till dissolves.

- Enter the preparation details in Format No. SOP/EN/XXXYYY.

- Start dosing the solution as per requirement.

Preparation of Sodium chloride solution

- Fill the regeneration tank with water.

- Make 30% solution of sodium chloride in tank as per chemical formula is mentioned at point 6.5

- Solution of sodium chloride can be prepared in low quantity depending on consumption.

- Stir the solution with SS rod till dissolves.

- Enter the preparation details in Format No. SOP/EN/XXXYYY.

- Start dosing the solution as per requirement.

Preparation of SMBS Solution

- Fill the dosing tank with water.

- Make 4% solution of SMBS in tank as per chemical formula is mentioned at point 6.5

- Solution of SMBS can be prepared in low quantity depending on consumption.

- Stir the solution with SS rod till dissolves.

- Enter the preparation details in Format No. SOP/EN/XXXYYY.

- Start dosing the solution as per requirement.

Preparation of Anti scalent Solution

- Fill the dosing tank with Purified water.

- Make 1% solution of Anti scalent in tank as per chemical formula is mentioned at point 6.5

- Solution of antiscalent can be prepared in low quantity depending on requirement.

- Stir the solution with SS rod till dissolves.

- Enter the preparation details in Format No. SOP/EN/XXXYYY.

- Start dosing the solution as per requirement.

Preparation of Alkali Solution

- Fill the dosing tank with Purified water.

- Make 4% sodium hydroxide Alkali solution in tank as per chemical formula.

- Solution of sodium hydroxide Alkali can be prepared in low quantity depending on consumption.

- Stir the solution with SS rod till dissolves.

- Enter the preparation details in Format No. SOP/ENXXXYYY.

- Start dosing the solution as per requirement.

Preparation of Acid Solution

- Fill the dosing tank with Purified water.

- Make 4% HCL Acid solution in tank as per chemical formula is mentioned at point 6.5

- Solution of HCL Acid can be prepared in low quantity depending on consumption.

- Stir the solution with SS rod till dissolves.

- Enter the preparation details in Format No. SOP/EN/XXXYYY.

- Start dosing the solution as per requirement.

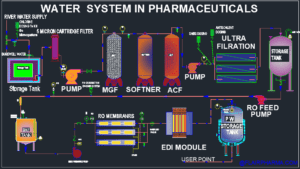

Purpose and dosing location of a solution:

| Sr.No. | Description | Purpose | Location |

| 1 | Sodium Hypochlorite solution | Chlorination of raw water | Pretreatment plant |

| 2 | Sodium Hydroxide solution | To maintain the pH | Water generation system |

| 3 | Sodium Chloride solution | To regenerate the softner | Pretreatment plant |

| 4 | SMBS solution | De-chlorination | Water generation system |

| 5 | Antiscalent solution | Prevent scales formation inside the RO | Water generation system |

| 6 | Alkali solution | For CIP of vessel | CIP system |

| 7 | Acid solution | For CIP of vessel | CIP system |

Dosing rate of the solution shall be calculated as per below formula:

Solution dosing (LPH) = Feed rate of water (m3/hr) × concentration of active reagent in PPM

10× Concentration of solution in %.

- Chemical preparation for solution shall be calculated as per below formula:

- Quantity of chemical required (A) = Required quantity of solution in ltr (B) × concentration of solution required in % (C) / concentration of the chemical received in %.(D)

- ake the quantity of chemical (A) obtained by above formula.

- Then make up the volume by adding the water up to required quantity of solution.

- Free chlorine concentration after SMBS solution dosing should be NMT 0.1 PPM and set dosing pump speed accordingly, record the free chlorine concentration on daily basis in Format No. SOP/EN/XXXYYY or when reset the dosing pumps speed.

- Dosing pump Stroke rate setting in %: LPH/Dosing pump capacity X 100 and add 10% in to the pump Knob setting. This is considering wear and tear losses of dosing pump.

- i.e. A = B × C

- D

Procedure for testing of free chlorine

- Components in free chlorine test kit.

- Comparator.

- Test Tube A & B

- Reagent Cl2-1 & Cl2-2.

- Take 3 drop of reagent Cl2-1 and 1 drop of reagent Cl2-2 in test tube A.

- Add 6 ml of sample water in test tube A, close the test tube cap and mix the sample.

- Take 6 ml of sample water in test tube B.

- Keep the test tube B &A behind of comparator in left hand side slots.

- Wait for colour change in test tube A for pink.

- Rotate the comparator and match the colour of test tube A & B.

- Take the reading from right hand side of comparator

- ABBREVIATIONS

- SMBS : Sodium Meta Bi-sulphate.

- cGMP : current Good Manufacturing Practice

- QA : Quality Assurance

- GMP : Good Manufacturing Practice

- SOP : Standard Operating Procedure

- LPH : Liter per hour.

- REFERENCES

- Nil.

- DISTRIBUTION LIST

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES

- Chemical preparation record : SOP/EN/XXXYYY

- Free chlorine recording : SOP/EN/XXXYYY

Preparation and Records of the Chemical Preparation in Water System

| CHEMICAL PREPARATION RECORD |

NAME OF SOLUTION:……………. Location:……………………….

| Date | Purified Water Quantity (in Ltr.) | Used Chemical Quantity | Discarded Quantity | Prepared by (Sign/Date) | Verified by (Sign/Date) |

FREE CHLORINE RECORDING

| After SMBS Dosing | ||||

| Date | Time | Free chlorine in PPM (Limit NMT 0.1ppm) | Done by (Sign/Date) | Remarks |