The purpose of this Standard Operating Procedure SOP for Preventive Maintenance of Laminar Air Flow Units, Mobile LAF, Dynamic Pass Boxes and Sterile Garment Cabinets. This procedure aims to ensure the optimal performance and cleanliness of these critical equipment, minimize contamination risks, and extend their service life.

SOP for Preventive Maintenance of Laminar Air Flow Units, Mobile LAF, Dynamic Pass Boxes and Sterile Garment Cabinets

- OBJECTIVE:

- To lay down the procedure for preventive maintenance of laminar air flow units, Mobile LAF, dynamic pass boxes and Sterile garment cabinets.

- SCOPE:

- This SOP is applicable to preventive maintenance of all laminar airflow units, Mobile LAF, dynamic pass boxes, and sterile garment cabinets installed at the production, warehouse, QC, and small-scale department.

- RESPONSIBILITY:

- Technician/ Operator / Engineer shall be responsible for proper execution of preventive maintenance as per SOP.

- Engineering – The Head shall be responsible for reviewing the SOP and for ensuring proper execution of preventive maintenance as per SOP.

- ACCOUNTABILITY:

- Engineering – The Head shall be accountable for the proper implementation of the SOP.

- DEFINITIONS:

- Nil

- PROCEDURE:

- Preventive maintenance shall be executed as per the SOP/EN/XXXYYY – Execution of Preventive Maintenance.

- Precautions:

- Ensure that the equipment power supply has been disconnected.

- Check that the equipment is in empty condition.

- Frequency:

- 6 months ± 15 days

- Check Points:

- The Following check points should be ensured during preventive maintenance:

- Clean all the electrical contacts with contactor cleaners.

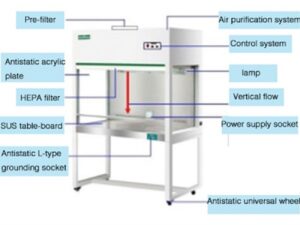

- Check the working of the blower and its motor, do lubrication if required.

- Check that the tubes of magnehelic gauge and ensure differential pressure reading is within range.

- Check the working of UV/fluorescent light.

- Verify working of U.V Meter versus U.V light and record in preventive maintenance checklist.

- Check the proper working of doors and interlocking of the same for pass boxes and garment cubicles.

- Check the pre-filters for choking and if required clean them.

- Check the battery voltage of Mobile LAF

- Check the UPS for Proper Working of Mobile LAF.

- Check the ON/ OFF push button for proper functioning.

- Record the details as per the Format No.: SOP/EN/010-F01 “Preventive Maintenance Checklist & Record for Laminar Air Flow Units, Mobile LAF, and Dynamic pass Boxes and Sterile Garments Cabinets”.

- Whenever any modifications and major works are carried out to the equipment, the same shall be mentioned in the equipment history card as per the SOP no. SOP/EN/XXXYYY

- Connect the equipment main power supply and start the equipment.

- Ensure that the equipment is running smoothly, without any abnormality.

- If any abnormality is observed in the above, same will be attended in co-ordination with User department Head.

- ABBREVIATIONS:

- CRF No. : Change Request Form number

- QA : Quality Assurance

- PM : Preventive Maintenance

- UV : Ultra Violet

- REFERENCES:

- Nil

- DISTRIBUTION LIST:

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES:

- Preventive Maintenance Checklist & Record for Laminar Air Flow : SOP/EN/XXXYYY

- Unit, Mobile LAF and Dynamic Pass Boxes and Sterile Garments Cabinets

| CHECKLIST & RECORD FOR LAMINAR AIR FLOW UNIT,MOBILE LAF, DYNAMIC PASS BOXES & STERILE GARMENTS CABINETS in SOP For Preventive Maintenance of Laminar Air Flow Units |

| Equipment Name | Location | ||

| Equipment ID | Frequency | 6 month ± 15 days |

| Things to be done: in SOP For Preventive Maintenance of Laminar Air Flow Units | Check List | Remark |

| Clean all the electrical contacts with contactor cleaners. | ||

| Check the working of the blower and its motor, do lubrication if required. | ||

| Check that the tubes of magnehelic gauge and ensure differential pressure reading is OK. | ||

| 4. Check the proper working of doors and interlocking of the same for pass boxes and garment cubicles. | ||

| 5. Check the pre-filters for choking and if required clean them. | ||

| 6. Check the ON/ OFF push button for proper functioning. | ||

| 7. Check the battery voltage of Mobile LAF. | ||

| 8. Check the UPS for Proper working of Mobile LAF. | ||

| 9. Check the Working of UV/florescent light. |

1. The Least count of hour meter is 0.01, After 36 sec reading of hour meter change HHHHHH.00 to HHHHHH.01, after 6 min reading of hour meter change HHHHHH.00 to HHHHHH.10 and after 1 hour reading of hour meter change HHHHHH.00 to HHHHH1.00 Hr.

2. Engineering person performing activity should hold calibrated stop watch in one hand and compare with the hour meter reading.

3. Engineering person has to perform Verification of the Hour Meter against a calibrated stop watch.

4. Observe the reading of both hour meter and calibrated stop watch and note down the both reading in checklist.

You may also read about Good Laboratory Practices (GLP)