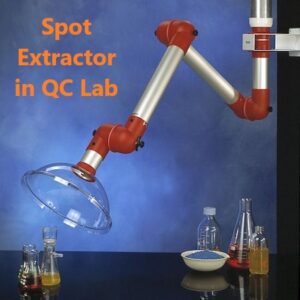

In the quality control (QC) laboratory of pharmaceutical industries, the spot extractor plays a crucial role in ensuring the integrity and quality of products. The spot extractor is a specialized instrument designed to extract and analyze specific components or analytes from pharmaceutical samples. It plays a vital role in the analysis and validation of raw materials, intermediates, and finished products.

The spot extractor in the QC lab offers several key benefits. Firstly, it enables the extraction of target compounds or impurities with high precision and accuracy. Selectively isolating and concentrating the desired components, it allows for thorough analysis and characterization. This is particularly important in pharmaceutical QC, where the identification and quantification of active pharmaceutical ingredients (APIs), excipients, and impurities are crucial for ensuring product safety and efficacy.

Additionally, the spot extractor facilitates the detection of trace levels of impurities or contaminants that may impact product quality. It enables the extraction of minute quantities of impurities, allowing for sensitive analysis and detection using techniques such as chromatography or spectroscopy. This capability helps to ensure compliance with regulatory standards and specifications, as even low levels of impurities can have significant implications for product safety and patient well-being.

Components of spot extractor

| Component | Description |

|---|---|

| Sample Holder | The sample holder is a platform or container that securely holds the sample during extraction. It ensures stability and proper positioning for accurate spot extraction. |

| Extraction Probe | The extraction chamber is an enclosed space where the sample, extraction probe, and solvent interact. It provides a controlled environment for the extraction process, minimizing external influences on extraction efficiency. |

| Solvent Reservoir | The solvent reservoir is a container that holds the solvents or extraction solutions used during the extraction process. It allows controlled dispensing of solvents to ensure optimal extraction efficiency. |

| Control Panel | The control panel is the interface through which the user interacts with the spot extractor system. It typically includes buttons, knobs, or a touchscreen for setting parameters, initiating extractions, and monitoring the extraction progress. |

| Heating/Cooling System | Some spot extractors incorporate a heating or cooling system to maintain the desired temperature during the extraction process. This feature is particularly useful for temperature-sensitive samples or specific extraction methods. |

| Extraction Chamber | Some spot extractors incorporate a heating or cooling system to maintain the desired temperature during the extraction process. This feature is handy for temperature-sensitive samples or specific extraction methods. |

| Collection Vials | Collection vials are containers that collect the extracted samples or analytes. They are designed to ensure proper sample storage and may have features such as labeling options or seals to maintain sample integrity. |

| Waste Container | The waste container is a designated compartment for collecting waste materials generated during the extraction process, such as used solvents or extraction residues. It helps maintain a clean and organized workspace. |

| Data Display and Recording | Spot extractors often feature a display screen for real-time monitoring of extraction parameters, extraction progress, and other relevant data. Some systems may also allow data logging for later analysis or documentation purposes. |

| Safety Features | Spot extractors may include various safety features, such as temperature and pressure sensors, emergency stop buttons, and safety interlocks to ensure safe operation and prevent accidents or mishaps. |

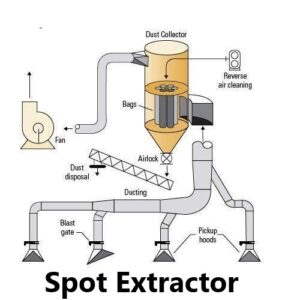

Working principle of Spot Extractor

The working principle of a Spot Extractor revolves around the concept of selective extraction and concentration of specific components or analytes from a sample. The Spot Extractor employs various techniques to achieve this objective, depending on the nature of the sample and the desired extraction method.

The process typically involves the following steps:

- Sample Preparation: The sample is prepared by either solidifying or liquefying it, depending on its original state. It is then positioned or loaded into a suitable holder or container within the Spot Extractor system.

- Extraction Probe Placement: The extraction probe, which can be a specialized tool or device, is positioned in close proximity to the sample. The probe is designed to come into contact with the sample and facilitate the transfer of desired components.

Spot Extractor GA drawing

- Solvent Dispensing: The Spot Extractor system dispenses a specific solvent or extraction solution onto the sample. The choice of solvent depends on the extraction technique and the nature of the target analytes. The solvent is carefully selected to solubilize or extract the desired components effectively.

- Interaction and Extraction: The solvent interacts with the sample, allowing for the extraction of the target components. This can occur through processes such as diffusion, dissolution, or partitioning, depending on the extraction method being employed. The solvent works to selectively extract the desired components while leaving unwanted substances behind.

- Concentration: The extracted components are then concentrated to increase their detectability or to reduce interference from other substances. This can be achieved through techniques such as evaporation, solid-phase extraction, or other concentration methods available in the Spot Extractor system.

- Collection: The concentrated extract is collected in a designated vial or container for further analysis. The collection process may involve automated mechanisms or manual transfer, depending on the system’s design and capabilities.

Throughout the entire process, the Spot Extractor system may incorporate various control parameters, such as temperature, pressure, or flow rates, to optimize extraction efficiency and reproducibility. These parameters can be adjusted based on the specific requirements of the sample and the desired extraction conditions.

Applications of the spot extractor system in pharmaceutical

| Application | Description |

|---|---|

| Drug Discovery | Spot Extractor Systems aid in the extraction and analysis of vast pharmaceutical datasets, enabling researchers to identify potential drug candidates and evaluate their efficacy. |

| Clinical Trials | These systems play a crucial role in extracting and analyzing data from clinical trials, assisting in the identification of safety profiles, treatment responses, and adverse events. |

| Pharmacovigilance | Spot Extractor Systems help pharmaceutical companies monitor and analyze adverse drug reactions and safety data, facilitating early detection and assessment of potential risks. |

| Quality Control | Spot Extractor Systems aid in the analysis of manufacturing data, enabling the optimization of processes, identifying areas for improvement, and enhancing overall operational efficiency. |

| Manufacturing Optimization | Spot Extractor Systems aid in the analysis of manufacturing data, enabling optimization of processes, identifying areas for improvement, and enhancing overall operational efficiency. |

| Regulatory Compliance | These systems assist pharmaceutical companies in extracting and analyzing relevant data for compliance with regulatory requirements, ensuring adherence to safety and quality standards. |

| Pharmacokinetics Studies | Spot Extractor Systems play a vital role in extracting and analyzing pharmacokinetic data, helping researchers understand drug absorption, distribution, metabolism, and excretion profiles. |

| Adverse Event Monitoring | These systems assist in the detection and analysis of adverse events reported post-marketing, allowing pharmaceutical companies to promptly assess safety concerns and take appropriate actions. |

| Drug Formulation Analysis | Spot Extractor Systems aid in the analysis of formulation data, assisting in the optimization of drug delivery systems and formulation development for enhanced therapeutic outcomes. |

| Marketing and Sales Analysis | These systems support pharmaceutical companies in extracting and analyzing market data, enabling effective marketing strategies and sales performance evaluation. |

Best Suppliers of spot extractor

These suppliers are recognized for their expertise and reputation in providing high-quality laboratory equipment. It is recommended to research and compare their offerings, including price, features, and customer reviews, to determine the best supplier for your specific needs. Here are some reputable suppliers:

- Thermo Fisher Scientific: Thermo Fisher Scientific is a global leader in scientific research and laboratory equipment. They offer a wide range of extraction systems and are known for their reliability and innovative solutions.

- Agilent Technologies: Agilent Technologies is a prominent supplier of laboratory instruments and equipment. They provide advanced extraction technologies and have a strong reputation for quality and performance.

- Waters Corporation: Waters Corporation specializes in analytical science solutions and offers spot extractors designed for various applications. They are recognized for their precision and analytical excellence.

- Shimadzu Corporation: Shimadzu Corporation is a leading manufacturer of analytical and scientific instruments, including spot extractors. They are known for their cutting-edge technologies and commitment to research and development.

- PerkinElmer: PerkinElmer is a trusted supplier of laboratory equipment and analytical solutions. They offer spot extractors designed for different sample types and provide comprehensive support for their products.

- Labconco Corporation: Labconco Corporation focuses on providing high-quality laboratory equipment, including spot extractors. They are known for their durable and user-friendly solutions.

- Eppendorf: Eppendorf is a renowned supplier of laboratory instruments and consumables. They offer spot extractors with advanced features and reliable performance.

Frequently Asked Questions

What is the primary function of a spot extractor in pharmaceuticals?

Answer: The primary function of a spot extractor in pharmaceuticals is to extract specific components or analytes from samples, allowing researchers to analyze and study their properties and characteristics.

What are the main extraction techniques used in pharmaceutical spot extractors?

Answer: Pharmaceutical spot extractors commonly employ techniques such as solid-phase extraction (SPE), liquid-liquid extraction (LLE), and supercritical fluid extraction (SFE) to extract desired components from samples.

How does a spot extractor ensure accuracy in the extraction process?

Answer: Spot extrctors ensure accuracy by maintaining controlled extraction conditions, precise sample handling, and accurate dispensing of solvents. The use of standardized protocols and calibration techniques also contributes to the accuracy of the extraction process.

What considerations should be taken into account when selecting a spot extractor for pharmaceutical applications?

Answer: When selecting a spot extrctor for pharmaceutical applications, factors such as sample compatibility, extraction efficiency, automation capabilities, solvent consumption, and regulatory compliance should be considered. The system’s robustness, reliability, and ease of use are also important factors.

Can a spot extractor handle a variety of sample types in pharmaceutical applications?

Answer: Yes, spot extrctors in pharmaceutical applications are designed to handle various sample types, including solid, liquid, and semi-solid samples. The versatility of the extraction probes and the ability to adjust extraction parameters ensure compatibility with a wide range of sample matrices.

How does automation contribute to the efficiency of spot extractors in pharmaceutical applications?

Answer: Automation in spot extrctors reduces manual labor, minimizes human error, and improves workflow efficiency. Automated features such as sample loading, solvent dispensing, and data recording enhance the overall efficiency and reproducibility of the extraction process.

What safety measures are incorporated in pharmaceutical spot extractors?

Answer: Pharmaceutical spot extrctors often incorporate safety features such as temperature and pressure monitoring, emergency stop buttons, and safety interlocks. These measures help ensure operator safety, prevent equipment damage, and maintain a safe working environment.

Can spot extractors be integrated with other analytical instruments in pharmaceutical laboratories?

Answer: Yes, spot extrctors can be seamlessly integrated with other analytical instruments such as chromatography systems, mass spectrometers, or spectroscopy instruments. This integration enables direct analysis of the extracted components, enhancing the efficiency of pharmaceutical analyses.

How are extraction parameters optimized in spot extractors for pharmaceutical applications?

Answer: Spot extrctors offer parameter optimization capabilities, allowing researchers to adjust parameters such as extraction time, solvent composition, temperature, and flow rates. Optimization is typically done through method development and validation studies to achieve the desired extraction efficiency and selectivity.

What are the potential future advancements in spot extractors for pharmaceutical applications?

Answer: Future advancements in spot extrctors for pharmaceutical applications may include enhanced automation and robotics, integration with artificial intelligence for intelligent extraction optimization, miniaturization of systems for point-of-care applications, and the development of new extraction techniques or materials to improve selectivity and sensitivity.

1 thought on “Spot Extractor in QC Lab 2023”