The vacuum transfer system in the granulation area of an Oral Solid Dosage (OSD) pharmaceutical plant is critical for ensuring the efficient and safe movement of powders and granules. This system is designed to handle bulk materials from the granulation process, which typically includes mixing, wet granulation, drying, and milling, and transferring them to subsequent stages such as blending, tablet compression, or encapsulation.

Working Principle of the Vacuum Transfer System for Powder in Pharma (PTS):

The vacuum transfer system for powder in the pharmaceutical industry is designed to transport bulk materials from one location to another using vacuum pressure. This system creates a vacuum within a sealed container, causing a pressure differential that moves the powder through a pipeline or hose. The material is conveyed to the destination, where it is discharged, often into a process machine such as a tablet press or mixer. This method ensures a clean, safe, and efficient transfer process, minimizing contamination and product loss

Step-by-Step Working Principle:

- Material Preparation:

- Granulation: The raw materials are mixed and granulated to form uniform granules. This can be done using wet granulation methods, where a binder solution is added, or dry granulation methods.

- Drying: The wet granules are dried to the desired moisture content using a fluid bed dryer or similar equipment.

- Loading into the Vacuum Transfer System:

- Material Hopper: The dried granules are fed into a hopper, which serves as the intake point for the vacuum transfer system.

- Inlet Valve: An inlet valve controls the flow of granules from the hopper into the vacuum pipeline. This valve ensures a consistent and controlled feed of material.

- Vacuum Generation:

- Vacuum Pump: A vacuum pump creates a low-pressure zone within the pipeline, generating the necessary suction force to draw the granules from the hopper into the pipeline.

- Pipeline: The pipeline is typically made of stainless steel or other pharmaceutical-grade materials to prevent contamination and ensure cleanability.

- Conveying:

- Vacuum Pressure: The pressure differential between the hopper and the destination point causes the granules to move through the pipeline.

- Air Flow: The air flow within the pipeline is carefully controlled to ensure that the granules are conveyed gently, minimizing damage and segregation.

- Separation and Filtration:

- Filter Separator: As the granules reach the end of the pipeline, they pass through a filter separator. This device separates the granules from the air stream, ensuring that only the granules are collected in the receiver.

- Air Filtration: The air is filtered through HEPA or ULPA filters to remove any residual particles before it is exhausted, maintaining a clean and safe working environment.

- Collection and Discharge:

- Vacuum Receiver: The granules are collected in a vacuum receiver, a sealed container designed to hold the material until it is ready for discharge.

- Discharge Valve: A discharge valve at the bottom of the vacuum receiver controls the release of granules into the next stage of the process, such as a blender or tablet press.

- Level Sensors: These sensors monitor the fill level of the receiver and trigger the discharge valve when the desired level is reached.

- Control System:

- Programmable Logic Controller (PLC): The entire process is controlled by a PLC, which ensures precise control over the vacuum levels, air flow, and material handling. The PLC is often equipped with a Human-Machine Interface (HMI) for easy operation and monitoring.

- Integration with Process Equipment:

- Blenders, Tablet Presses, and Encapsulation Machines: The vacuum transfer system can be integrated with various process equipment, allowing for seamless transfer of granules to the next stage of production without exposure to the environment.

Technical Specifications of the Vacuum Transfer System:

| Specification | Description |

| Material | Stainless Steel (typically 316L) |

| Capacity | 50 – 5000 kg/hour |

| Vacuum Pump | Dry or Oil-Lubricated |

| Filtration System | HEPA or Ultra-Low Penetration Air (ULPA) filters |

| Control System | Programmable Logic Controller (PLC) with Human-Machine Interface (HMI) |

| Power Supply | 220V/380V, 50/60Hz |

| Discharge Valve | Full opening discharge valve for complete material discharge |

| Connectivity | Compatible with existing process equipment and control systems |

| Safety Features | Explosion-proof design, automatic shutdown features |

| Compliance | GMP, FDA |

| Conveying Distance | Up to 100 meters |

Key Benefits in the Granulation Area

- Efficiency: Automates the transfer process, reducing manual labor and increasing throughput.

- Safety: Minimizes dust generation and exposure, enhancing worker safety.

- Quality Control: Maintains product integrity by reducing the risk of contamination and segregation.

- Compliance: Adheres to strict pharmaceutical industry standards and regulations.

The vacuum transfer system in the granulation area of an OSD pharma plant ensures a smooth, efficient, and contamination-free transfer of granules, playing a crucial role in maintaining the high standards required for pharmaceutical production.

➡️👉Options of the PTS is Lifting device or Lifting & tilting devices.

Advantages & Disadvantages of Vacuum Transfer System for Powder in Pharma

| Advantages | Disadvantages |

|---|---|

| Reduces manual handling and labor costs | Initial setup cost can be high |

| Minimizes contamination and dust generation | Requires regular maintenance |

| Ensures consistent and controlled transfer | May not be suitable for very sticky materials |

| Enhances safety by reducing manual lifting | Limited by conveying distance and capacity |

| Compatible with various process equipment | Requires proper system design for efficiency |

Applications of the Vacuum Transfer System

| Application | Description |

| Tablet Press Loading | Automated conveying of tablet granulations to tablet presses |

| Gel Cap Conveying | Transfer of gel caps, soft gels, or tablets to packaging lines |

| Direct Charge Blender Loading | Loading of blenders and mixers with bulk materials |

| Collection of Wastes/Wastewater | Assists in compliance with wastewater disposal regulations |

| Delivery of Excipients and Active Ingredients (APIs) | Precise and contamination-free transfer of sensitive materials |

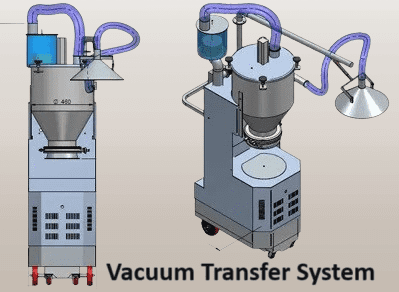

Types of Vacuum Transfer Systems for Powder in Pharmaceuticals

In the pharmaceutical industry, vacuum transfer systems are employed to efficiently and safely transport powders and granules. These systems vary based on their design, application, and operational principles. Here are the main types of vacuum transfer systems used in the pharmaceutical sector:

1. Dilute Phase Vacuum Conveying

Description: In dilute phase vacuum conveying, powders are transported through the pipeline at high velocities with a low product-to-air ratio. The material is suspended in the air stream, creating a fast-moving flow.

Features:

- High air velocity (15.2 to 35.6 m/sec)

- Low product concentration

- Suitable for non-fragile, non-cohesive materials

Applications:

- Transfer of bulk powders

- Loading materials into mixers and blenders

- General material transport where segregation and attrition are not major concerns

2. Dense Phase Vacuum Conveying

Description: Dense phase vacuum conveying involves the transport of powders at low velocities with a high product-to-air ratio. The material moves in a plug flow, reducing the risk of damage and segregation.

Features:

- Low air velocity (0.4 to 8.6 m/sec)

- High product concentration

- Gentle handling of materials

Applications:

- Transfer of fragile or sensitive powders

- Feeding materials to tablet presses or encapsulators

- Transporting pre-blends and granulations

3. Continuous Vacuum Conveying

Description: Continuous vacuum conveying systems are designed for continuous operation, ensuring a steady supply of material to process equipment. These systems are often integrated with continuous manufacturing processes.

Features:

- Continuous material flow

- Integrated with process control systems

- Suitable for large-scale production

Applications:

- Continuous feeding of reactors, mixers, and blenders

- Supplying material to continuous tablet press lines

- Integrated with continuous granulation processes

4. Batch Vacuum Conveying

Description: Batch vacuum conveying systems transport materials in discrete batches rather than continuously. These systems are suitable for applications where precise amounts of material are required.

Features:

- Batch processing capability

- Precise control over material quantities

- Suitable for intermittent operations

Applications:

- Feeding batch mixers and blenders

- Transferring materials in batch manufacturing processes

- Loading materials into hoppers for batch processing

5. Mobile Vacuum Conveying Systems

Description: Mobile vacuum conveying systems are portable units that can be moved between different locations within a facility. These systems offer flexibility for various material handling tasks.

Features:

- Portable and flexible

- Can be used for multiple applications

- Easy to clean and maintain

Applications:

- Transferring materials between different process areas

- Temporary material handling needs

- Cleaning and maintenance operations

6. Customized Vacuum Conveying Systems

Description: Customized vacuum conveying systems are designed and built to meet specific requirements of a pharmaceutical manufacturing process. These systems are tailored to handle unique materials, environments, or process conditions.

Features:

- Tailored to specific needs

- Specialized components and designs

- Optimized for unique material properties

Applications:

- Handling highly potent compounds

- Specialized transfer needs in cleanroom environments

- Customized integration with existing equipment and processes

Comparison Table :

| Type | Air Velocity | Product Concentration | Typical Applications |

| Dilute Phase | 15.2 to 35.6 m/sec | Low | Bulk powder transfer, mixer loading |

| Dense Phase | 0.4 to 8.6 m/sec | High | Fragile powder transfer, tablet press feeding |

| Continuous | Variable (low to medium) | Medium to high | Continuous manufacturing, reactor feeding |

| Batch | Variable (medium) | Medium | Batch processing, hopper loading |

| Mobile | Variable (medium) | Medium | Temporary transfer, maintenance operations |

| Customized | Customizable | Customizable | Specialized needs, potent compound handling |

Frequently Asked Questions (FAQ’s)

What is the principle of vacuum powder transfer system?

Answer: The principle of a vacuum powder transfer system involves creating a vacuum to move powders and granules through a sealed pipeline. A vacuum pump generates a low-pressure area within the system, causing atmospheric pressure to push the material through the pipeline. The material is typically drawn from a hopper or container, conveyed through the pipeline, and collected in a receiver where the vacuum separates the material from the air. This method ensures a dust-free, contained transfer of materials.

What is the use of vacuum in pharmaceutical industry?

Answer: In the pharmaceutical industry, vacuum systems are used for:

- Powder Transfer: Moving powders and granules between processes without contamination.

- Drying: Vacuum dryers remove moisture from pharmaceutical products more efficiently.

- Packaging: Vacuum systems are used in packaging processes to ensure airtight seals.

- Filtration: Vacuum assists in filtering processes to separate solids from liquids.

- Sterilization: Vacuum steam sterilizers ensure complete sterilization of equipment and materials.

What is a powder transfer system?

Answer: A powder transfer system is a mechanical setup used to move powdery substances from one part of a manufacturing process to another. It typically includes components such as hoppers, conveyors, pipelines, and vacuum pumps to ensure efficient, safe, and dust-free transfer of powders.

What is the mechanism of a vacuum system?

Answer: The mechanism of a vacuum system involves:

- Vacuum Generation: A vacuum pump creates a low-pressure area.

- Material Intake: The vacuum draws material from a source into a pipeline.

- Conveying: The material is transported through the pipeline due to the pressure differential.

- Separation: Material is separated from the air stream in a receiver.

- Discharge: The material is discharged into the next stage of the process.

What are the basic principles of vacuum?

Answer: The basic principles of vacuum include:

- Pressure Reduction: Lowering the pressure inside a vessel below atmospheric pressure.

- Pressure Differential: Utilizing the difference between the internal low pressure and external atmospheric pressure to move materials.

- Gas Flow: Managing the flow of gas molecules from a higher pressure area to a lower pressure area.

What is the purpose of a vacuum?

Answer: The purpose of a vacuum is to create a low-pressure environment that can be used for various applications such as:

- Material Transfer: Moving powders and liquids.

- Drying: Removing moisture efficiently.

- Filtration: Enhancing the separation of substances.

- Sterilization: Ensuring the sterility of equipment and materials.

- Packaging: Ensuring airtight packaging for products.

What are vacuum systems used for?

Answer: Vacuum systems are used for:

- Material Handling: Transporting powders and granules.

- Drying Processes: Removing moisture from materials.

- Filtration: Enhancing separation processes.

- Sterilization: Sterilizing equipment and materials.

- Packaging: Ensuring airtight seals in packaging.

What are the advantages of vacuum techniques?

Answer: Advantages of vacuum techniques include:

- Contamination Prevention: Reduces exposure to contaminants.

- Efficiency: Enhances the speed and efficiency of processes.

- Safety: Minimizes dust and improves safety conditions.

- Precision: Allows for precise control over processes.

- Versatility: Can be used in a wide range of applications.

What is the PTS system for powder transfer?

Answer: The PTS (Powder Transfer System) is a specialized vacuum conveying system designed for the safe and efficient transfer of powders and granules in pharmaceutical and other industries. It integrates well with various process equipment and ensures dust-free, contained transfer.

How is powder transported?

Answer: Powder is transported using methods such as:

- Vacuum Conveying: Using vacuum to draw and move powders through pipelines.

- Pneumatic Conveying: Using air pressure to push powders through pipelines.

- Mechanical Conveyors: Using belts, screws, or vibrating systems to move powders.

What are the methods of powder processing?

Answer: Methods of powder processing include:

- Milling: Reducing particle size.

- Blending: Mixing powders to achieve uniformity.

- Granulation: Forming granules from powders.

- Drying: Removing moisture from powders.

How does a vacuum work?

Answer: A vacuum works by creating a low-pressure area through the removal of air or gas. This low-pressure zone causes materials or gases to move from areas of higher pressure to areas of lower pressure, enabling various industrial processes such as conveying, drying, and filtering.

What is the theory of vacuum?

Answer: The theory of vacuum involves the concept of reducing pressure within a closed system below atmospheric pressure, creating a differential that can be utilized for movement, processing, and containment of materials and gases.

What is the concept of a vacuum?

Answer: The concept of a vacuum is the creation of a space with significantly reduced pressure compared to atmospheric pressure, resulting in a low-density environment where the effects of air resistance and pressure are minimized.

What is the principle of PTS?

Answer: The principle of the Powder Transfer System (PTS) is to use vacuum to create a low-pressure environment that draws powders and granules from one location to another, ensuring a contained, efficient, and dust-free transfer process.

What is the use of PTS?

Answer: The PTS is used for:

- Transferring Powders: Moving powders between processing steps.

- Feeding Process Equipment: Supplying powders to mixers, blenders, and tablet presses.

- Ensuring Containment: Reducing dust and contamination.

What is powder handling system?

Answer: A powder handling system is an integrated setup designed to manage the movement, storage, and processing of powders in a controlled and efficient manner. It includes equipment such as hoppers, conveyors, vacuum systems, and filters.

What is the principle of powder transfer system?

Answer: The principle of a powder transfer system involves creating a pressure differential (usually by vacuum or pneumatic means) to move powders from one location to another within a manufacturing process, ensuring containment and efficiency.

What is powder testing?

Answer: Powder testing involves assessing the physical properties of powders, such as particle size distribution, flowability, compressibility, and moisture content, to ensure they meet the required specifications for processing and final product quality.

What are the methods of powder handling?

Answer: Methods of powder handling include:

- Vacuum Conveying: Using vacuum to move powders.

- Pneumatic Conveying: Using air pressure to transport powders.

- Mechanical Conveying: Using belts, screws, or vibratory systems.

- Manual Handling: Manual scooping and transfer.

What are the methods of powder flow?

Answer: Methods of powder flow include:

- Gravity Flow: Utilizing gravity to move powders from higher to lower points.

- Pneumatic Flow: Using air or gas to push powders through pipelines.

- Vibratory Flow: Using vibrations to encourage powder movement.

- Mechanical Flow: Using mechanical means such as screw conveyors or belt conveyors to move

Manufacturer for the Vacuum Transfer System for Powder in Pharmaceutical industry in India

Check it 👉➡️ PTS by CoralPT Worldwide Pvt. Ltd.

Your writing is a true testament to your expertise and dedication to your craft. I’m continually impressed by the depth of your knowledge and the clarity of your explanations. Keep up the phenomenal work!