Lifting and Tipping Unit (LTU) / Lifting & Positioning Unit (LPU)

The Lifting & Positioning Devices are used to transfer and discharge the material dust-free and without human touch with products help to control the contaminations. In pharmaceutical industries, these devices are used to Load powder into Tablet Compression Machine hoppers, RMG, Sifters, etc.

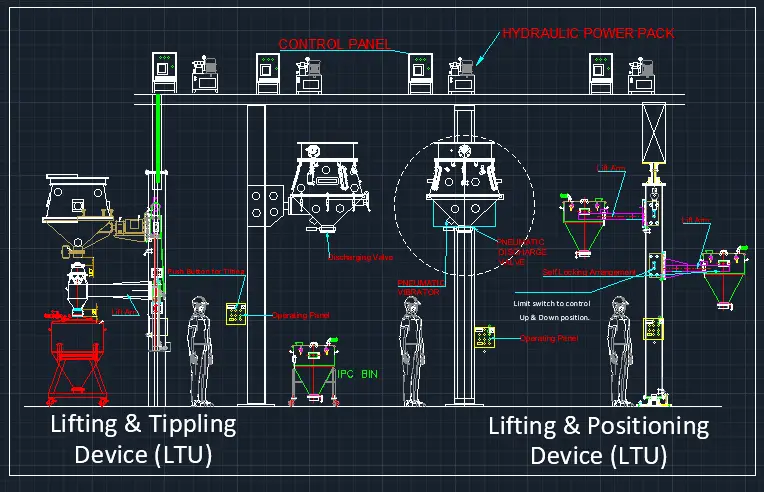

Lifting and Tipping Unit (LTU) / Lifting & Positioning Unit (LPU) Complete setup.

Working Principle:

The Lifting & Positioning Unit / IPC Bin loader is used in the pharmaceutical industry to transport and discharge the material dust-free and without human contact for loading powder into the hopper of the tablet compression machine. It is made up of a pivot base, a mainframe, a bin fastening arm, and a hydraulic lifting device.

Introduction: what is LTU?

Lifting devices are used to lift, Tipper & lower the Bins and FBD bowls in the Granulation area of every pharmaceutical industry. These devices are operated hydraulically & pneumatically & lift the Bins & fill Sifter, RMG, Mills, SCM/Multi mill /Quandromil l/Oscillating granulator, and tipping the FBD bowl FBD.

Technical Specifications: what is LTU technology?

LTU and LPU are customs designed to lift and position any type of container or bin. These units are constructed/made using various s assemblies which helps with the different operation and product transfer of solid dosage manufacturing and also for liquid compounding operation. These LPU &

Lifting and Tipping Unit :

also, reduce the contamination and human intervention in products and also help to achieve dust-free transfer of drug in-process product materials. These systems are also enhancing the cGMP standard. Now one new system also working in pharma industries i.e., the Product Transfer System (PTS) with the help of piping and vacuum pump systems.

Material of Construction (MOC) & Technical details.

- Contact Parts are of SS316/SS316L

- Non-Contact Exposed Parts

- Column and its Cover: Rectangular or cylindrical column is used to house the hydraulic cylinder and the guide box to lift the Bin to the desired height. The column is grouted at the top & bottom.

- Panel and its Covers

- Bowl Holding Arm SS304

- Elastomers in contact with Material

- Lifting Arrangement: Double acting hydraulic cylinder is mounted with two pulleys on its piston head. Two wire ropes are passed over the pulleys. The wire ropes are fixed at the back of the column and the front ends are tied to the sliding head. The sliding head is fitted with the cone lifting and tilting assembly.

- Gaskets Food Grade Silicon

- Vibrator: In Build, the vibrator to discharges 100% material.

- LTU/LPU both have bins with pneumatically operated butterfly valves and shall have self-locking arrangements.

- Control the ON/OFF switch

- Push Button Up & Down movement.

- Indication Lamps.

- Push the Button for Tilting.

Safety Features:

- Interlocks, Maximum Up/Down Height possible only up to set Proxy switch position. And E-Stop provision for Stopping all operations.

- Product Safety All internal surfaces have smooth rounded edges. Internal surfaces smooth mirror Polished.

- Drive Flameproof

- Electricals Flameproof

- Surface Finish Internal – 240 Grit Mirror

- External – 180 Grit Matt

- Noise Levels Below 80 decibels at 3.5 feet from the machine

Documents for Machines:

- URS

- FAT Document

- Design Qualifications

- GA Drawing

- As-Built Drawings

- Motor TC

- Operation / Instruction Manual

- Warranty Certificate

- Electrical Circuit Diagram

- MOC certificate

- Food Grade Certificate for Gasket

- Contact Surface Area Certificate with Calculation.

- IQ and OQ.

Original Equipment Manufacturers (OEM), Best Manufactures in India:

There are many manufacturers in India who supplied the LPD setups, basically, the equipment is the supporting equipment to the main OSD equipment. Some of the best suppliers are:

- Bowman And Archer

- Anish pharma Equip. Pvt ltd.

- Saan Engineering Pvt. Ltd.

- Bectochem Loedige

- Brothers Pharmamach

- Saimach Pharmatech

Budget or Cost for New Equipment in India:

In India, the cost of these lifting devices start from 6 lacs to 20 lacs and varies as per the loading capacities and safety feature.

There are many suppliers Indian as well as foreign who manufactured this equipment. To Know the best supplier in Granulation Lines, technically as well as commercially, please write us at: admin@flairpharma.com.

1 thought on “Working and Technology of Lifting Tipping Unit LTU, LPU”