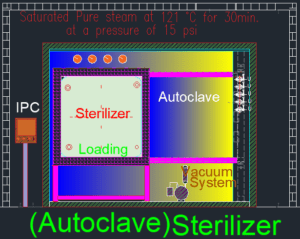

Autoclave also named Steam sterilizers and very known equipment for the pharma industry. Stam sterilizer used for the sterilization/ disinfection (HPHV/HPLV) of solutions, equipment, dresses, and other articles required for working in an aseptic area of the pharma or biotech facility

Types of Autoclave (Steam Sterilizers)

On the basis of the design & shape, there are the following types of equipment available in the market:

- Horizontal Cylindrical Sterilizer.

- Sliding Door Horizontal Steam Sterilizer

- Horizontal Rectangular Sterilizer.

- Double Walled Vertical Autoclave.

- Triple Walled Vertical Autoclave.

System Description:

- The sterilizer is primarily intended for sterilizing porous, non-porous as well as mixed-type loads using saturated steam with required pre and post-sterilization vacuum pulses.

- The equipment will be with double doors and the doors will be operated by pneumatic cylinders. The sterilization processes are run, fully automatically as per the selected cycle.

- The appliance works with steam at positive pressure, produced by a Pure Steam Generator Or Clean, dry saturated steam from your boiler plant duly filtered.

- A water-ring vacuum pump creates pre-and post-vacuum, which makes the sterilizer suitable for porous materials such as garments as well.

- The sterilizer requires connections to the electric power and steam and compressed air supply with suitable drainage for hot effluents.

Construction requirements

- Chamber Volume: …. Ltr

- The door can be pneumatically operated (Horizontal/Vertical), which will be decided after looking into technical feasibility.

- Inner chamber material DIN 1.4571 (AISI 316Ti). Jacket, piping, valves, and external surface DIN 1.4301 (AISI 304). The inner chamber surface finish should be Ra ≤ .09 µm.

- Vacuum break filter 0.2m hydrophobic filter.

- Proper insulation of all hot surfaces.

- All parts to be subjected to a pressure over 3 bar should be designed and manufactured in line with the current National /International standards for pressurized containers. All standards are to be adopted for the construction of steam sterilizers.

- All non-metal parts in contact with the feed water and steam should be of proper materials as per FDA regulations or equivalent.

- Provision for estimation of non-condensable gases.

Utility Requirements: –

- To be fed with Purified Steam (Pure Steam) from the PSG in the chamber and raw steam in the jacket.

- Other quantitative utility requirements such as power/steam requirements for the operation of the machine shall be provided by the vendor.

Operational Requirements: –

- Adjustable operating temperature up to 135o C. Error ± 0.5 C with an empty chamber.

- Following cycles are required.

- High-pressure high Vacuum cycle.

- High-pressure high temperature cycle (With vacuum pulsing).

- Automatic F0 value calculation for each cycle.

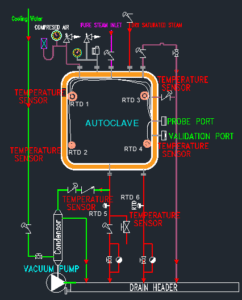

- PLC control with data recording facility for temperature (6 points) and pressure. Software should have three-level access controls.

- Indicator for Steam pressure in chamber and jacket.

- Indicator for temp. at different points in the chamber.

- Temp. Control at the drain point.

- Temp. And pressure monitoring and recording during the sterilization process.

- Steam pulsing and vacuum pulsing are to be provided.

Details of the sterilization cycle shall be recorded with each and every cycle, following are the parameters-

- Date.

- Load Number.

- Set parameters (Time, temp, vacuum stage-wise).

- Cycle time.

- Cycle temp.

- Interruptions.

- In case of power failure manual override should be provided.

Alarms and Safety Requirements:

| Sr. No | Parameter | Indicator | Regulator | Control | Alarm | |

| 1 | low and high temp | √ | √ | √ | √ | |

| 2 | Sterilization temp. not reached | √ | √ | √ | √ | |

| 3 | low steam pressure | √ | √ | √ | √ | |

| 4 | Vacuum fail | √ | √ | √ | √ | |

| 5 | Sterilization cycle time | √ | √ | √ | √ | |

| 6 | Jacket temp. | √ | √ | √ | √ | |

| 7 | Air | √ | X | √ | √ | |

| 8 | Door Open | √ | X | √ | √ |

- Audio visual alarm for low and high temp.

- Audio visual alarm for sterilization temp. not reached.

- Audio visual alarm for low steam pressure.

- Pressure gauges and safety valve.

- Door interlocking

Validation/Documentation Requirements:

- Have access ports for temperature and pressure verification tests, Validation port for the insertion of 16 temperature probes.

- The machine must comply with routine validation requirements such as temperature distribution, heat penetration, vacuum /pressure leak test, etc, as per the applicable standards.

- Calibration document of all instruments with at least 90% shelf life at the time of FAT.

Documentation Requirements:

- Design specification

- Factory Acceptance Test (FAT)

- Site Acceptance Test (SAT)

- Design Qualification (DQ)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Operational manual (2 Sets)

- Maintenance Manual (2 Sets)

- Software operation manual (2 Sets)

- Safety manual (2 Sets)

- Validation protocols

- Certificates of MoC of all contact parts, filters, and all instruments.

- Welding certificates

- Biological compatibility certificates of all non-metallic parts.

- Other certificates should be delivered after performing relevant tests/calibrations before installation.

Diffrent Cycles in the Autoclave:

The following programs can be selected for this type of sterilizer.

- Vacuum leak (Autoclave integrity) test.

- Bowie Dick test.

- Standard Programme (Slow and Fast Exhaust).

- HP/HV.

- SIP of Vent Filter.

Frequently Asked Questions:

What is the main principle of autoclave?

Answer: An autoclave is a device that offers a physical way of sterilization by employing steam under pressure to destroy bacteria, viruses, and even spores contained in the material placed inside the vessel. By heating the materials to a given temperature for a set amount of time, an autoclave sterilizes the materials. The autoclave, which is also known as a steam sterilizer, is frequently used in healthcare facilities and other commercial settings for a variety of functions. Because it relies on wet heat sterilization, the autoclave is regarded as a more successful sterilizing technique.

How does autoclave work step by step?

Answer: Following are the step-by-step detail of the autoclave working:

- Put the autoclave with the goods to be sterilized inside. The entrance is secured.

- Air is removed from the chamber using a vacuum pump.

- The temperature is at the proper setting.

- Microbes and bacteria are destroyed by steam.

- The door is opened, the steam is let out, and the equipment is now used.

What is the principle of autoclave temperature?

Answer: The temperature of 121°C of pure moist steam is used to kill the microorganisms. The results in a temperature of 121 °C. Depending on the amount of the load, the time needed to autoclave at 121°C to achieve sterilization is often estimated to be between 15 and 20 minutes. To guarantee that sterilization is effective, one should make sure. Remember that the high temperatures that may be reached when steam is put under pressure are what kills the bacteria, not the autoclave’s pressure. When sterilizing large things, heat conduction to the interior will be slow, so the heating period must be long enough for the object to reach 121°C for 15 minutes. Large quantities of liquids must be autoclaved for longer periods of time since they take longer to attain sterilizing temperature.

What is the function and use of autoclave?

Answer: The main function of the autoclave is to sterilize the equipment of instruments that are used for sterile activities. Since materials containing water cannot be sterilized by dry heat sterilization, autoclaves are crucial tools to ensure the sterilization of those materials. Moreover, autoclaves provide a number of other functions.

They are used to sterilize lab equipment, sterilize media, and decontaminate certain biological waste.

Before disposal, it is advised to autoclave regulated medical waste that may contain bacteria, viruses, and other biological materials.

Autoclaves are used in medical labs to sanitize medical waste, glassware, surgical instruments, and equipment.

Similar to this, pipette tips, plastic tubes, autoclavable containers, and culture medium are all sterilized in autoclaves.

What is the basic principle of steam sterilization?

Answer: The basic principle of the autoclave is only it operates on pure steam w& kills the microorganism with the help of moist steam temperature and pressure.

What is the principle and working mechanism of autoclave?

Answer: The autoclave operates according to the moist heat sterilization concept. For equipment sterilization, the high pressure inside the chamber raises the boiling point of water. Moreover, the higher pressure ensures that heat will quickly reach the deeper components of the equipment. The moisture in the steam induces the coagulation of microbial protein, which results in an irreparable loss of activity and function.

What are the 4 methods of sterilization?

Answer: Followings are the four method for the sterilization:

- Moist Heat Sterilization

- Sterilization by dry heat.

- Sterilization by radiations

- Sterilization by ethylene oxide

What are the 3 types of sterilization?

Answer: Followings are the three types of sterilizer

- Dry heat Sterilizer (DHS).

- Most Steam Streilizer (Autoclave).

- Radiation sterilizer.

1 thought on “Working Principle of Autoclave (Steam Sterilizer) 2023”