Bulk Packing & Counting Line for tablets/capsules:

In the Pharmaceutical industry, Bottle Packing lines are commonly used for packing tablets and capsules. Various types of plastic bottles are used for drug packing so that the Bottle Packing line for tablets or capsules. The major process that is used in Bottle Packing Line is as below:

- Bottle Unscrambling

- Desiccant Insertion

- Bottle Counting

- Check weigher

- Cot toner

- Bottle Capping

- Bottle Cap sealing

- Bottle Cap Retorqued

- Bottle Labelling

- Leaflet out setter

- Bottle Carting

- Carton Shrink Bundler

Process & working of Bulk packing Line/ Bottle Packing line:

- The Bulk packing line has an entry turn table which is used to provide directions to the bottles towards the Airjet Cleaner.

- Then the bottles get cleansed with the help of air purging.

- After that, the bottles are directed toward the Counting Machine where the bottles are filled with product at the set count directed by the system.

- After the bottle is filled it is diverted towards Silica Gel Inserter Machine which dispenses the pouches/tablets/capsules in the bottles.

- After silica pouches is been dispensed, the bottle is directed toward the Rayon/ Cotton Inserter Machine which inserts the rayon/ cotton in the bottle.

- After that, the bottles are diverted toward the Capping Station where they bottle is capped at the required torque.

- Then the bottle is transferred to the Induction Sealer Machine which gets the bottle sealed with the foil on the cap of the bottle.

- After that, the bottle goes to the 2D Printing Station where it gets the code printed below the bottle with the help of inkjet printing,

- After that, the bottle goes to the labeling station where it gets labeled.

- Then directed toward the exit turn table as a final product.

- After that bundle of bottles is filled in the carton or shipper & send to the market.

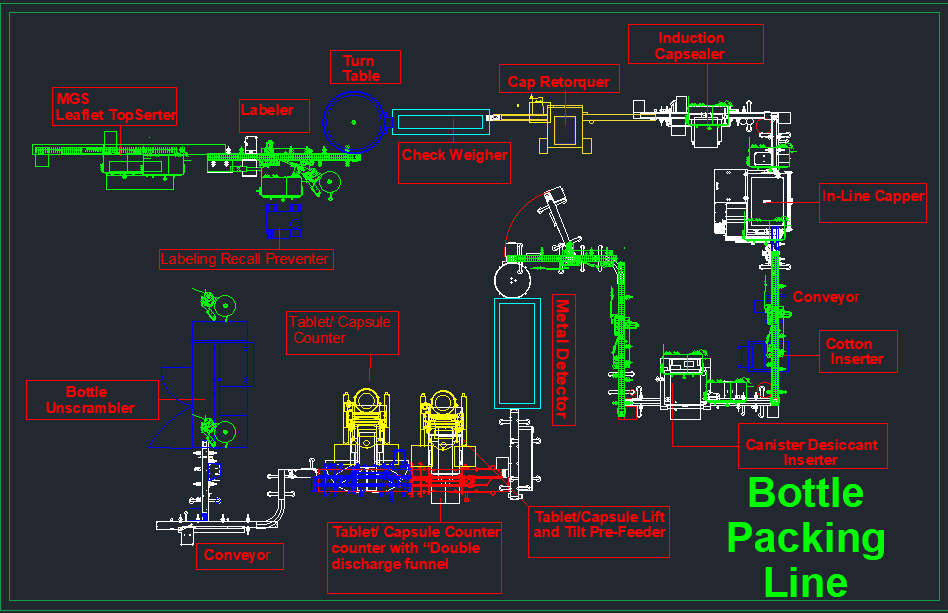

Major Components of the Bottle Packing line :

- Turntable

- Bottle Unscrambler

Bottle counter - Tablet/ Capsule Counter

- Conveyors

- Tablet/Capsule Lift and Tilt Pre-Feeder

- Canister Desiccant Inserter & Conveyor

- Check weigher

- Cotton Inserter & Conveyor

- Metal Detector

- In-Line Capper & Conveyor

- Induction Cap sealer & Conveyor

- Cap Retorquer and Conveyor

- Labeler and Conveyor

- MGS Top Serter

- Catenator

- Shirk wrapping machine

Working principle of Bulk Packing & Counting Line for tablets/capsules.

The working principle of a Bottle Packing line / Bulk Packing & Counting Line for tablets/capsules revolves around a series of systematic steps that ensure efficient packaging and accurate counting. Here’s an overview of the working principle:

- Feeding and Orientation: The tablets or capsules are fed into a hopper or feeder, where they are stored in bulk. From the hopper, they are directed toward a vibratory bowl or sorting unit. The vibratory motion helps to orient the tablets or capsules in a specific direction, ensuring proper alignment for subsequent counting.

- Counting: Once the tablets or capsules are oriented, they move to the counting mechanism. This mechanism employs sensors or imaging technology to detect and count the products as they pass through. It accurately tracks the number of tablets or capsules, ensuring precise counting.

- Conveying: After counting, the tablets or capsules move along a conveyor system. The conveyor system facilitates the smooth and continuous flow of the counted products, transporting them to the packaging stage.

- Packaging: At the packaging stage, the counted tablets or capsules are enclosed in individual packages. Depending on the packaging format, such as blister packs, bottles, or pouches, the packaging machine handles the necessary operations. This includes sealing the packages, creating compartments for each tablet or capsule, and ensuring proper closure.

- Labeling and Printing: Once the tablets or capsules are packaged, a labeling and printing unit applies labels containing essential information. This includes details like product identification, dosage instructions, lot numbers, and expiry dates. The labeling and printing unit ensures compliance with regulatory requirements and facilitates accurate identification of the packaged products.

- Inspection: Quality control is an integral part of the Bulk Packing & Counting Line. Inspection systems are incorporated to check for any defects or errors in the packaging process. These systems employ advanced technologies, such as vision inspection or metal detection, to identify issues like broken tablets, empty packages, or misaligned labels.

- Integration with Secondary Packaging: In some cases, the Bulk Packing & Counting Line can be integrated with secondary packaging equipment. This allows for a seamless transition of the packaged products to cartoning machines or case packers, where they are further processed for bulk packaging or shipment.

Throughout the working process, the Bottle Packing line, Bulk Packing & Counting Line employs automation and advanced technology to ensure efficiency, accuracy, and product integrity. By automating the counting and packaging stages, pharmaceutical manufacturers can significantly reduce manual labor, enhance productivity, and minimize errors in the packaging process.

In summary, the Bulk Packing & Counting Line operates by systematically feeding, counting, conveying, packaging, labeling, and inspecting tablets or capsules. This sophisticated line of equipment streamlines the packaging process, ensuring reliable and accurate packaging for pharmaceutical products.

Critical Parameters and key features of Bulk Packing & Counting Line

| Critical Parameters | Key Features |

|---|---|

| Feeding System | – Controlled and consistent feeding of tablets/capsules from a hopper or feeder. |

| – Ensures a continuous supply of products for counting and packaging. | |

| Counting Mechanism | – Accurate counting of tablets/capsules using sensors or imaging technology. |

| – Precisely detects and counts the products as they pass through the line. | |

| Conveyor System | – Smooth and continuous transport of counted tablets/capsules to the packaging stage. |

| – Minimizes disruptions and maintains a steady flow of products. | |

| Packaging Machine | – Encloses counted tablets/capsules into individual packages (blister packs, bottles, pouches, etc.). |

| – Seals packages, creates compartments and ensures proper closure. | |

| Labeling and Printing | – Application of labels with product information, dosage instructions, lot numbers, and expiry dates. |

| – Ensures compliance with regulatory requirements and accurate identification of packaged products. | |

| Inspection Systems | – Integration of vision inspection or metal detection systems for quality control. |

| – Identifies defects, such as broken tablets, empty packages, or misaligned labels. | |

| Integration | – Possible integration with secondary packaging equipment, such as cartoning machines or case packers. |

| – Streamlines the transition to bulk packaging or shipment processes. | |

| Automation | – Utilizes automation technology for efficient and reliable counting and packaging. |

| – Reduces manual labor, enhances productivity, and minimizes errors. |

Conclusion:

Any pharmaceutical firm that plans to purchase a bulk packing line or Bottle Packing line must ensure seamless integration between each of the separate machines. And choose the best software to integrate the line. Plants require a high-efficiency line machine that decreases the production cost and can boost productivity with less downtime and less changeover time, which may lead to the growth of their factory.

Certification & Documentations in Bottle Packing line:

- GA Drawing & P&ID, Complete set of Top, Side & Elevation view.

- MOC certificates of all contact & major non-contact parts.

- The complete set of DQ, and IQ and all documents are as per URS.

Best (OEMs) Manufacturers of Bottle Packing Line:

World wide there are many manufacturers who make Bottle Bulk packing lines, Some of the well-known manufacturers are:

- CVC technology.

- Pharmapack Technologies Corporation

Elmec Technopac Machineries Private Limited.

The cost of the bulk Bottle Packing line varies from 2 cr to 5 cr.

FAQ:-

What is CVC packing?

Answer: For the pharmaceutical and nutraceutical industries, CVC is a US-based company that offers whole packaging lines for tablets and capsules. The tablet counter is the focus of every effective packaging line for tablets or capsules, and CVC technology provides the best models on the market.

How many types of tablet packing are there?

Answer: There are many types of tablet packing machines/ Bottle Packing line are their:

- Tablet in bottle packaging.

- Aluminum foil packaging

- PVC foil packaging

- Strip packaging.

- Aluminum foil.

What is the full form of CVC Technologies?

Answer: CVC Technologies is a manufacturer or OEM for the complete equipment setup for packing lines to pack the medicines. So CVC is the Name of that company.

What is the purpose of a Bottle Packing Line / Bulk Packing & Counting Line for tablets/capsules?

Answer: The purpose of a Bottle Packing Line / Bulk Packing & Counting Line is to efficiently package and count tablets or capsules, ensuring accurate quantities and reliable packaging for pharmaceutical products.

What are the key components of a Bottle Packing Line / Bulk Packing & Counting Line?

Answer: The key components typically include a feeding system, counting mechanism, conveyor system, packaging machine, labeling and printing unit, inspection systems, and integration capabilities with secondary packaging equipment.

How does the feeding system work in a Bottle Packing Line / Bulk Packing & Counting Line?

Answer: The feeding system controls the consistent supply of tablets or capsules from a hopper or feeder, ensuring a continuous flow of products for counting and packaging.

How does the counting mechanism accurately count tablets or capsules in the line?

Answer: The counting mechanism utilizes sensors or imaging technology to detect and count the tablets or capsules as they pass through, accurately tracking the number of products for precise counting.

What role does the conveyor system play in the line?

Answer: The conveyor system transports the counted tablets or capsules smoothly and continuously, facilitating their movement to the packaging stage without disruptions, ensuring a steady flow of products.

What packaging formats can be handled by the packaging machine in the line?

Answer: The packaging machine can handle various packaging formats, including bottles, blister packs, pouches, or other customized packaging options suitable for tablets or capsules.

How does the labeling and printing unit contribute to the packaging process?

Answer: The labeling and printing unit applies essential labels containing product information, dosage instructions, lot numbers, and expiry dates, ensuring compliance with regulatory requirements and accurate identification of the packaged products.

What is the purpose of inspection systems integrated into the line?

Answer: Inspection systems detect and identify defects, such as broken tablets, empty packages, or misaligned labels, ensuring high-quality control and preventing defective products from reaching the market.

Can the Bottle Packing Line / Bulk Packing & Counting Line be integrated with other packaging equipment?

Answer: Yes, the line can be seamlessly integrated with secondary packaging equipment, such as cartoning machines or case packers, to streamline the overall packaging process and enable efficient bulk packaging or shipment.

How does automation technology contribute to the efficiency of the line?

Answer: Automation technology in the Bottle Packing Line / Bulk Packing & Counting Line reduces manual labor, enhances productivity, and minimizes errors, ensuring efficient and reliable counting and packaging operations.

For more technical details about the Bottle Packing line, best equipment vendor comparison, or any type of documentation. (SOP,DQ,IQ,OQ,PQ etc.) Please contact: admin@flairpharma.com

1 thought on “Best Bottle Packing Line for Tablet or Capsule 2025”